- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Fused Deposition Modeling (FDM) has emerged as one of the most popular and accessible 3D printing technologies, changing how we approach design, prototyping, and manufacturing.

These printers offer a diverse range of features and capabilities to cater to the needs of hobbyists, professionals, and businesses alike and are being applied in creating durable final-use products and prototypes across various industries.

This guide lists the best 3D printers for FDM processing for beginners and seasoned manufacturers alike.

What is an FDM 3D printer?

An FDM 3D printer is an additive manufacturing technology that uses a material extrusion process to create 3D objects layer by layer. In this process, a spool feeds thermoplastic filament through an extruder that heats, melts, and extrudes the plastic through a thin nozzle onto a build plate.

An FDM printer typically consists of extruding nozzles on linear slides, a build platform on another linear slide, and supports for plastic filament spools. These printers work with various thermoplastic 3D printing materials: polymers that melt when heated and solidify when cooled.

How fused deposition modeling works

The first few steps of FDM 3D printing are similar to other additive manufacturing technologies. It begins by designing a digital version or 3D model of the object to be printed using build preparation software, also known as computer-aided design (CAD) software.

After the 3D model is created, it is exported in a 3D printable file format, usually STL or OBJ, to a slicer software where information about the object, such as layer height, orientation, and infill percentage, is chosen.

The slicer software then slices the model into layers and generates extruder paths and building instructions based on this data. The information is loaded into the 3D printer which is in turn loaded with a thermoplastic filament spool of choice for building both the model and a support structure.

The FDM 3D printer build platform is heated to control material cooling, and the extruders are heated to melt the filament. When the nozzles reach the right temperature, the extruder then pushes and melts the filament, depositing it layer by layer onto the build platform.

The extrusion head and build platform move in three axes to deposit material accurately. After all layers are built, the part is removed from the platform, supports are removed, and post-processing may be done to finish the part for its intended use.

Best FDM 3D printers

From high-speed industrial printers to beginner-friendly desktop options, some of the best FDM 3D printers include:

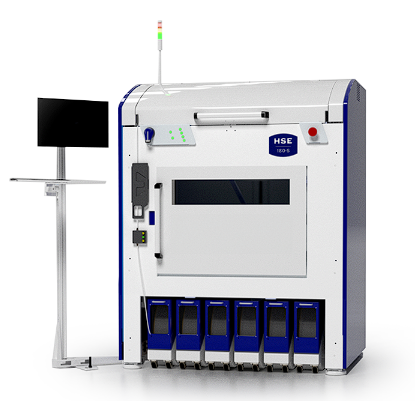

1. Nexa3D HSE 180 Series

The Nexa3D HSE 180 series advanced industrial 3D printers are high-speed extrusion 3D printing platforms equipped with linear servo motors, enabling them to reach a remarkable five to fifteen times the speed of their competitors. They are designed to address longstanding challenges in additive manufacturing, specifically tackling issues related to strength, speed, and scalability.

The Nexa3D HSE 180 series achieves printing speeds of up to 500 mm/sec using linear servo motors to minimize wasted movement. These printers boast an impressive 1G acceleration and a swift 1 m/sec travel speed to print high-quality products quickly, with record-high increases in daily throughput compared to traditional FDM printers.

Besides unmatched printing speeds, the HSE 180 series is equipped with large build volumes to efficiently produce substantial components with rapid speed and robustness on a generously sized build plate that accommodates 85% of the world’s jigs and fixtures. Its open ecosystem makes it one of the best 3D printers for printing an extensive range of thermoplastic materials, including engineering-grade Essentium materials.

The Nexa3D HSE 180 series catalogue includes three printers, the HSE 180LT, the HSE 180ST, and the HSE 180HT. These printers are used in all industries, from commercial manufacturing to aerospace, defense, automotive, and transportation. They print everything from prosthetic sockets to 3D-printed tools, manufacturing aids, and high-temp jigs and fixtures.

Specifications:

- 690 x 500 x 600 mm build volume

- 0.081 mm XY and 0.005 mm Z motion system accuracy

- Hozzle™ heated nozzle

- One print head

- Works with 1.75 mm filament diameter

- 1G acceleration

- 1 m/sec movement speed

- 4 KVA, 220/240V 20A for LT machine and 40A for ST and HT machines, Single Phase 50/60 Hz electrical requirements

- Prints low-temperature, standard, and high-temperature materials

- Compatible with the NexaX and Dentflow 3D printer software

Explore all HSE 180 3D printer models.

2. Nexa3D HSE 280i

The Nexa3D HSE 280i is another advanced industrial 3D printer designed to revolutionize manufacturing processes by outpacing the competition. This HSE280i overhauls factory floor operations using an X-Y stage equipped with linear servo motors to deliver printing speeds of up to 500 mm/sec and a swift 1 m/sec travel speed–speeds five to 15 times faster than traditional FDM printers.

This large 3D printer boasts true independent dual extruders (IDEX) that provide complete autonomy for each head along both the X and Y axes. This function enables the HSE 280i HT printer to achieve versatile printing options like support material, identical parts, or unique parts simultaneously.

Besides these innovative features, the HSE 280i printer also uses a non-slip, high-torque extrusion system to deliver an uncompromising printing solution. By providing both speed and reliability to enable seamless 3D printing at scale, the HSE 280i redefines the possibilities of additive manufacturing.

Specifications:

- Build volume: 695 x 500 x 600 mm (Single head mode), 595 x 500 x 600 mm (support mode), 595 x 500 x 600 mm (Multi-process mode)

- True independent dual extruders (IDEX)

- 500 mm/s print speed

- Two print heads

- 5 printing modes: single head mode, copy mode, multi-process mode, support mode, and independent mode

- 1.75 mm filament diameter

- 1590 x 1350 x 2490 mm printer dimension

- Open ecosystem to process diverse materials

Learn more about the Nexa3D HSE 280i.

3. Stratasys F370

The Stratasys F370 offers a large build volume of 355 x 254 x 355 mm and supports a wide range of high-performance materials, including ABS, ABS-CF10, FDM TPU 92A, and Diran 410MF07. The Stratasys F370 has auto-calibration, fast material swaps, and compatibility with the GrabCAD Print software.

Specifications:

- 355 x 254 x 355 mm (14 x 10 x 14 in.) build volume

- 4 material bays (2 models and 2 supports)

- Supports GrabCAD Print, GrabCAD Print Pro3 Insight

- Supports Ethernet connectivity

- Requires Windows 7, 8, 8.1 and 10

4. Bambu Lab X1C

The Bambu Lab X1 series are desktop printers with multi-color capabilities. The printer is air-tight with a humidity sensor, 2-stage feeding, filament buffer, provision for snap-away supports, Bambu Micro Lidar for high precision, dual auto bed leveling, and spaghetti detection for structural confidence.

The Bambu Lab X1C comes in a wear-resistant steel chassis, can operate in silent mode below 50db, and prints PA, PC, and carbon/glass-reinforced materials.

Specifications:

- 256 × 256 × 256 mm³ build volume

- All-metal hotend that reaches up to 300°C

- Maximum speed of 500mm/s and maximum acceleration of 20 m/s²

- Lidar sensor and power loss recovery

- Filament runout sensor and door sensor

- 5-inch 1280 × 720 touch screen and remote control

5. Bambu Lab P1S

The Bambu Lab P1S is a mid-range 3D printer that provides access to full-color printing. It offers up to 16-color printing with AMS and comes with a PEI build plate, a built-in camera for remote monitoring and timelapse, and an enclosed-body for high-temperature filament printing. The Bambu Lab P1S also comes with auto bed Leveling and vibration compensation.

Specifications:

- 256 x 256 x 256 mm build volume

- Max speed of 500mm/s and max acceleration of 20m/s2

- Direct-drive extruder and filament runout sensor

- Fan and carbon filters

- Multi-color capability

- Compatible with Bambu Studio for remote control

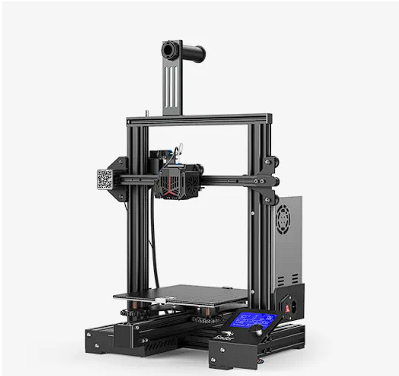

6. Creality Ender 3 V2 Neo

The Creality Ender 3 V2 Neo is an FDM 3D printer with a sturdy gantry for stable printing. It comes with CR touch auto-leveling, a full-metal Bowden extruder, a bendable PC spring steel magnetic build plate, and a silent mainboard that enables low-decibel operation.

The Creality Ender 3 v2 Neo printer supports PLA, PETG, and ABS filaments.

Specifications:

- 220 x 220 x 250 build volume

- Maximum print speed of 120mm/s

- 4.3-inch color knob screen

- 1 nozzle with 0.4mm diameter that reaches 260°C

- 32-bit silent mainboard

- PC spring steel magnetic build plate

- Compatible with Creality Slicer/Cura/Simplefy 3D

- Resume printing function and CR touch auto leveling

7. Elegoo Neptune 4 Pro

The ELEGOO Neptune 4 Pro is designed for quiet operation below 50 decibels using silent drivers. It comes with a Klipper motherboard, smart segmented heat bed, wear-resistant POM V-guide wheels, four auxiliary fans for omnidirectional rapid cooling, dual-gear direct drive extruders, a 300°C high-temp nozzle, and a removable touchscreen.

The ELEGOO Neptune 4 Pro prints a range of materials, such as PLA, PETG, ABS, ASA, TPU, and high-temp filaments like nylon.

Specifications:

- Print volume at 225 x 225 x 265 mm³

- Max print speed of 500 mm/s

- Intelligent segmented heatbed

- 121 (11 x 11) points auto bed leveling

- Up To 300 °C high-temp nozzle

- Support PLA/TPU/PETG/ABS/ASA/Nylon filaments

- USB/LAN transfer

8. AnyCubic Kobra Plus

The Anycubic Kobra Plus has a build volume of 350 x 300 x 300 mm that caters to small and large designs. It offers a typical print speed of 100mm/s, modular design, fast leveling, and a user-friendly touch-screen.

The Anycubic Kobra Plus also features a carborundum glass print bed that locks parts down during printing, a filament runout sensor, and an intuitive color touchscreen interface. It is compatible with many filaments, including ABS, PLA, and Anycubic color filaments.

Specifications:

- 350 x 300 x 300mm (13.8 x 11.8 x 11.8in.) build volume

- Printing speed of about 100 mm/s

- Replaceable nozzle with ø 0.4mm size

- 4.3″ resistive touch-control screen

- Power-Loss Recovery function

- Nozzle temperature around 260°C

9. Stratasys Fortus 450mc

The Fortus 450mc by Stratasys has a build volume of 406 x 355 x 406 mm. It supports a wide range of standard, engineering-grade, and high-performance thermoplastic materials, including ABS, ASA, PC, Nylon 12, and ULTEM 1010.

The Fortus 450mc can become an open system when used with an OpenAM material license and associated software. It is typically used to produce custom tools, prototypes, and low-volume parts across various industries.

Specifications:

- 16 x 14 x 16 inches (406 x 355 x 406 mm) build volume

- Compatible with 16 materials

- Up to 500 x 500 x 500 in cartridge capacity

- Limited attendance for job start and stop required

- 208VAC 3 phase, 50/60 Hz, consumes 18 Amps power requirements

- Operates on Microsoft Windows

FDM 3D Printing Overview

Some more information about FDM include:

What are FDM printers best for?

FDM printers are best for cost-effective productions using various thermoplastic materials with varying mechanical and chemical properties to create prototypes, jigs, fixtures, and even small-batch production parts.

Advantages of FDM 3D printing

There are several advantages of FDM over other 3D printing technologies. These include its user-friendliness, which makes it suitable for beginners, reliability, repeatability, ability to print a wide range of thermoplastic materials, and cost-effectiveness, which makes it accessible for hobbyists, beginners, and small 3D printing services alike.

FDM 3D printer price

The cost of an FDM 3D printer depends on its size, capabilities, and functions. For example, FDM printers for beginners and hobbyists typically have fewer professional features and cost between $100 and $500, while large industrial options like Nexa3D HSE 280i are more advanced printers for professional manufacturing and cost between $10,000 and $100,000+.

While FDM printers typically cost less upfront than other technologies like resin 3D printers, there are more factors to consider when running 3D printing costs. These include project specifications, printing materials, maintenance, manpower costs, and energy consumption.

FDM 3D Printing vs Resin 3D Printing

Resin 3D printing, a technology that uses vat polymerization processes to cure liquid photopolymers into structures, and FDM are two of the most common 3D printing technologies today.

Some common differences between them include:

3D Printing Materials

Filament 3D printers work with a range of standard thermoplastic filaments, such as ABS, PLA, and their various blends. The technology also works with engineering materials, such as Nylon, PETG, PA, or TPU, and high-performance thermoplastics like PEEK or PEI.

Resin 3D printing, including processes such as stereolithography (SLA) or mSLA 3D printing (masked stereolithography), uses a liquid photopolymer resin material that is cured by UV light to create objects.

3D Printer Speeds

FDM printers can vary in speed depending on the model and settings, with some like Nexa3D HSE 180 series offering faster output rates than others. Resin 3D printers, on the other hand, can be generally slower than FDM printers but can achieve higher resolutions, making them suitable for intricate designs and small-scale models.

Nexa3D’s filament printers are a top choice when it comes to combining precision with speed. With a platform that offers up to 500 mm/s of printing speed and 5-15 times the printing speed of average filament 3D printers, the Nexa3D filament printers are some of the fastest 3D printers in the market today.

Resolution

FDM typically has a lower resolution than SLA because it deposits heated filaments in layers. These layers may not fully meld into one another, making them clearly visible on the surface. In SLA 3D printing, liquid resin is cured by a highly precise laser or light projection with high repeatability, leading to the production of finer details and a higher resolution.

Applications & Industries

FDM printers are commonly used for rapid prototyping, tooling, and custom production or mass customization due to their cost-effectiveness and versatility. SLA printers such as the Nexa3D XiP and XiP Pro used for 3D printing with polymers, are preferred for applications requiring high detail and precision, such as the manufacturing of custom dental prosthetics or orthopedics.

These printers are also ideal for flexible 3D printing using flexible resin materials to make things like functional prototypes, pipes, and manifolds.

Choose the Best Filament 3D Printer

FDM 3D printing offers many possibilities for creators, innovators, and businesses looking to push the boundaries of what’s possible.

To enjoy the numerous advantages this additive printing process offers, it is essential to invest in the right hardware and choose the best filament 3D printers.

Although every printer on our list offers swift printing speed and high-quality operations, Nexa3D’s range of filament 3D printers provides unprecedented capabilities, including smarter operations and the fastest print speed in the market today.

Designed with automation and scalability in mind, Nexa3D printers offer high quality, precision, accuracy, and large build volumes to accommodate numerous printing needs.

Ready to experience it yourself?