- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Since the advent of 3D printing technologies in the 1980s, there has been increasing interest in using polymers and their composites due to their high efficiency, resolution, and customization capabilities. 3D printing with polymers occurs by depositing polymers layer by layer to form a completed part.

Polymer 3D printing only continues to advance, allowing 3D professionals to use additive manufacturing technology to create end-use parts, functional prototypes, and complex geometries.

This guide will cover everything you need to know about 3D printing with polymer materials, including polymer 3D printing technologies and the benefits and challenges of this type of 3D printing.

What is Polymer 3D Printing?

Polymer 3D printing technology is a type of additive manufacturing (AM) that can create three-dimensional objects by depositing materials layer by layer. Instead of using metals or ceramics, polymer 3D printing uses polymers – long chain molecules made up of repeating units – as its primary material.

Polymer printing uses extrusion, resin, and powder 3D printing processes to provide versatility for material selection and support designs with diverse architectures, responses, and layouts not possible with other technologies. This technology can print using a wide range of commercially available polymers, including acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polycarbonate (PC), poly ether ester ketone (PEEK), polyetherimide (ULTEM) and thermoplastic elastomers (TPE).

PLA is the most common material used because of its ease of use; it undergoes minimal expansion and contraction when heated and cooled. While the other materials provide superior performance characteristics, they’re more expensive and difficult to print.

Polymer 3D Printing Technologies and Processes

Polymer 3D printing technologies dominate the additive manufacturing industry as the preferred technology for producing end-use parts, functional prototypes, and complex geometries.

Polymer 3D printing technologies and processes include:

Vat Polymerization with Resin

Vat photopolymerization is an additive manufacturing technique that produces 3D objects by selectively curing photopolymer liquid resin through light-activated polymerization. The build platform is lowered into, or raised out of, a vat of liquid photopolymer resin.

The object is created by projecting light or a laser onto the build platform. This causes the photopolymer to solidify and adhere to the platform. After each layer is cured, the build platform is lowered or raised slightly, and a new photopolymer layer is introduced. This process is repeated until the object is complete.

Resin 3D printers are now available in three generations. The first generation, Stereolithography (SLA), uses a laser to draw out each layer, the second, Digital Light Processing (DLP), uses a projector chip to project a full layer of curing light, and the third, Masked Stereolithography (mSLA), uses an LCD panel to project a full layer of curing light.

Masked stereolithography (mSLA), the latest evolution of SLA, uses an LED array rather than a laser or a single projection point. The LED array directs light through an LCD panel, masks the necessary pixels while printing, and allows only necessary pixels to pass light. As a result, only the unmasked part cures.

The best masked stereolithography (mSLA) 3D resin printers use Nexa3D’s Lubricant Sublayer Photo-curing (LSPc) technology. The patented variant of the mSLA resin 3D printer combines a UV light array and LSPc optical lens layer to ensure light uniformity in this 3D printing process, which is critical for the optimal use of the LCPc High Contrast Mask.

For example, Nexa3D’s XiP professional desktop 3D printer combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes for any desktop. Patented under Nexa3D’s LSPc technology, it addresses common concerns over usable power, image homogeneity, heat buildup, layer separation, and resin replenishment cycles during the build process.

The LSPc High Contrast Mask is responsible for projecting 3D image slices onto the vat where the photopolymerization process occurs layer-by-layer. This combination creates a high edge-to-edge performance with no distortion.

Powder Bed Fusion

In powder bed fusion, a laser or an electron beam selectively melts the powder material layer by layer. The process begins with a layer of powder spread evenly over the build platform and then the laser or electron beam fuses the powder to form the desired shape. The build platform is lowered, and another layer of powder is spread over it.

The most common type of powder bed fusion is selective laser sintering (SLS). In sintering, the powder is heated below its melting point. This causes the particles to bond without changing the object’s overall shape. In melting, the powder is heated above its melting point, which allows it to flow and take on the desired shape.

Powered by Quantum Laser Sintering technology, Nexa3D’s QLS 820 delivers premium production capabilities with incredible speed, end-to-end traceability, centralized printer management, real-time data monitoring, and the highest throughput in its class.

The QLS 820 is about 60% faster than the existing industry standard with double the average packing density. With four times more power and throughput compared to competitor models, this thermoplastic 3D printer can produce up to four times the throughput of traditional laser sintering 3D printers and other polymer powder bed technologies.

Material Extrusion

Material extrusion is a 3D printing technology that uses a continuous material filament to create objects. The process begins with the material, typically plastic filament, being fed through a heated nozzle. The nozzle melts the material and deposits it onto the build platform.

The deposition process is controlled by a computer-aided design (CAD) file, which dictates the path of the extruded filament. The object is then built layer by layer until it is complete.

Material extrusion is commonly known as fused deposition modeling (FDM) or fused filament fabrication (FFF). FDM technology is best for creating large parts with simple geometries from various materials.

Material Jetting with Resins

Material jetting with resins involves the process of printing objects with photopolymer resins. This printing process works the same way as a 2D printer: a printhead (similar to the printheads used in regular inkjet printing) dispenses droplets of a photosensitive polymer material that solidifies under ultraviolet light. This technology dispenses viscous liquids to create wax-like parts which have applications in investment casting.

Material jetting parts have high dimensional accuracy and a smooth surface finish. Multi-material printing is possible and it’s compatible with a wide range of materials, including ABS-like, rubber-like, and fully transparent materials.

Polymer 3D Printing Applications

Polymer 3D printing is a versatile technology used for different applications in a variety of industries.

1. Medical Devices

The medical industry was one of the first to adopt additive manufacturing due to the need for custom-made implants and prosthetics. Polymer 3D printing has been driving innovative solutions and influencing the evolution of medical devices.

With polymer 3D printing, medical professionals can produce patient-specific implants that are a perfect fit. Polymer 3D printing technology enables more agile product development, new final-use parts, and the fabrication of tailored medical devices that would be challenging to create with existing tools and technologies.

The combination of speed, accuracy, and affordability makes polymer 3D printing the perfect technology for producing low-volume batches of medical devices. For instance, rapid prototyping is a group of techniques used to fabricate a full-scale model of physical parts or assemblies using three-dimensional computer-aided design (CAD) data. In the medical industry, this can create prototypes of new devices that can be tested before mass production.

Dentistry is another area that has benefited immensely from polymer 3D printing technology. With polymer 3D printing, dental professionals can create custom-fit crowns, bridges, and implants in a matter of hours. What would normally take days or weeks can now be done in a fraction of the time – making it possible to provide same-day service to patients.

The Nexa3D’s NXD 200Pro proves how dental 3D printing technology is being used to quickly print custom dental implants in-office. The NXD 200Pro has an unprecedented 8.5L build volume measuring 275 x 155 x 200 mm (10.8 x 6.1 x 7.8 inch) and patented LSPc technology. This makes the dental 3D printer ideal for dental models, splints, impression trays, occlusal night guards, and more. The superior speed and workflow are complemented by intuitive interfaces and ease of use, perfect for dental labs.

Polymer 3D printing also helps in surgical pre-planning. Professionals print models of a patient’s anatomy to help the surgeon understand the problem area and plan the surgery. The models can be created from medical images such as CT or MRI scans.

2. Industrial Manufacturing and Construction

The construction industry uses 3D printing technology to produce custom-fit parts and prototypes quickly and easily. Builders are adopting polymer 3D printing to construct office buildings, homes, and other structures. 3D-printed buildings can span thousands of square feet and multiple stories and are more affordable than traditional construction methods.

For civil engineers, polymer 3D printing offers a way to quickly produce prototypes of bridges, roads, and other structures. The technology is also used to create full-scale models of proposed buildings and structures. Currently, sophisticated devices can print buildings in a matter of days using polymer 3D printing technology.

A perfect example is the world’s first 3D-printed commercial building, the Dubai Future Foundation (DFF). The 250 sqm office building was printed using a 20m x 40m concrete printer in just 17 days, costing less than $100,000.

3. Engineering, Designing, and Prototyping

Engineers and designers can use polymer 3D printing to create prototypes of parts and products. The technology offers a fast, efficient way to produce prototypes that can be used for testing and evaluation. Product designers can also use 3D visualization technology to go beyond the limitation of pictures and create full-color, moving images of their products.

Nexa3D’s NXE 400Pro provides exceptional affordability for designers, engineers, and manufacturers who need fast, accurate, and cost-effective prototyping and manufacturing solutions.

The XiP is a best-in-class desktop resin 3D printer that offers the ultimate flexibility. Users can create consistent, high-quality parts and prototypes with reliability and repeatability using both Nexa3D validated resin and third-party materials.

4. Consumer Products

Consumer products made with polymer 3D printing technology are becoming more common. These products include toys, eyewear, phone cases, and home décor items.

As Polymer 3D printing technology continues to evolve, it will profoundly impact how more industries operate. The technology is here to change products’ designs, manufacturing, and distribution through its versatile and affordable way of creating parts and products.

Polymer 3D Printing Benefits

Here are some of the top benefits of using polymer 3D printing technology:

Reduced Costs

3D printing with polymers can help businesses reduce the cost of manufacturing by eliminating the need for tooling and assembly. Since polymer 3D printing is fast and efficient, businesses can save money on inventory costs by only producing parts and products when they are needed.

Plus, 3D printing is an additive process. In subtractive manufacturing, parts are created by cutting away materials from a block until the desired shape is achieved. Additive manufacturing builds objects layer-by-layer, resulting in less waste and reduced need for materials.

Rapid Prototyping

mSLA technologies have drastically reduced production time by using LCD light engines to project UV light across the build platform to cure a full layer of the print at once.

And while mSLA itself is one of the fastest technologies, Nexa3D’s LSPc technology goes a step further utilizing a patented lubricated sublayer called the Everlast 2 membrane. This membrane significantly reduces the “peel force” imposed as each layer is lifted off of the base of the vat.

The result is an open architecture, reflector-based light engine. It’s equipped with a 200-diode LED array for maximum light generation, a 13-inch 4K high-resolution LCD mask sitting between the membrane and LEDs, and a duct and blower design that efficiently cools the projector area. This provides the fastest printer on the market with the largest build area in its class, all without sacrificing image quality.

With Nexa3D’s polymer printers, you can go from weeks and days of print time to hours and minutes.

Learn more about all of Nexa3D’s printers.

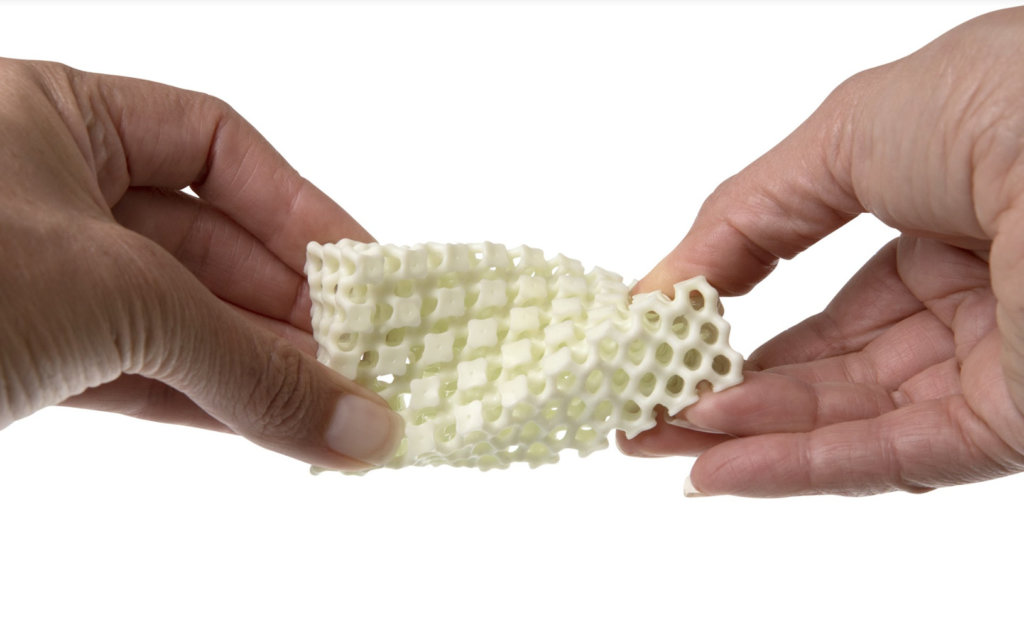

Increased Complexity

3D printing offers better printing qualities for complex designs. The technology can create parts with intricate designs that would be impossible to create with traditional manufacturing methods. Resin 3D printers can print resolutions as low as 10 microns, creating products with very fine features and a reduced need for post-processing.

Improved Sustainability

Polymer 3D printing reduces the need to mass produce plastic components that could quickly become obsolete and go to waste. It also enables on-demand printing of exactly the quantity you need when you need it, so manufacturers no longer need vast inventories of unused parts.

Plus, 3D printing can lower transportation and logistics costs – thereby reducing an organization’s overall carbon footprint.

Polymer 3D printing challenges

Despite the many benefits of 3D printing, some challenges still need to be addressed. Here are some limitations of using polymer 3D printing technology:

Quality and Speed Tradeoff

In traditional manufacturing and even 3D printing with other materials, it’s often necessary to sacrifice speed for quality. However, with the best polymer 3D printers, it’s possible to have both high-quality products and short production times.

Nexa3D’s LSPc technology addresses common concerns over usable power, image homogeneity, layer separation, resin replenishment cycles, and heat buildup during the build process, making it the most successful at solving the historical speed vs. quality problem.

Managing Heat Production

The heating and cooling process of polymer 3D printing can produce undesirable results, such as warping and cracking. These problems can be prevented by using a 3D printer with active temperature control.

Nexa3D’s LSPc technology uses an internal chamber heater and an external build plate cooling system to ensure that the build area is kept at a consistent temperature. This results in less warping and cracking, and ultimately, higher-quality parts.

Work with the best polymer 3D printing technology

Polymer 3D printing allows for more versatile, efficient, and customizable 3D printing. And with the right polymer 3D printing tools and an experienced team, any business can harness the power of 3D printing to create high-quality parts and products.

Nexa3D makes ultrafast 3D printers for designers, engineers, and manufacturers who need to develop and manufacture excellent products. It offers the fastest 3D printers on the market with the largest build area in its class without sacrificing image quality – all while using affordable, long-lasting, and readily available components.

If you’re ready to move from days or even weeks of prototyping and development time to hours or minutes, Nexa3D is the solution.

Experience polymer 3D printing technology by requesting a free sample part.

Or, keep learning with our 2023 ultrafast 3D printing material guide.