- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Rapid prototyping is the quick creation of a preliminary 3D model or part that can be used to evaluate a product’s functionality or design. Rapid prototyping processes often use 3D computer-aided design and 3D printing technology to create prototypes faster and more affordably than through traditional manufacturing methods.

To utilize rapid prototyping with 3D printing, designers and printers need the right software tools and the best 3D printers that can print quickly and accurately while preserving function.

This guide will explore the basics of rapid prototyping, 3D prototyping examples, and how to 3D print prototypes.

What is Rapid Prototyping in 3D Printing?

Rapid prototyping is a general term for a range of manufacturing processes that uses technology to create physical models quickly and cost-effectively. Engineers, designers, and manufacturers often use this process for prototyping new products or testing design modifications.

Rapid prototyping utilizes a digital CAD software (Computer Aided Design) design to allow for faster turnaround time between when changes are made to a design and final printing. 3D printing technology is then used to create the prototype.

It’s important to note that rapid prototyping is not the same as 3D printing. Rapid Prototyping is a broader term that involves creating prototypes using various manufacturing processes like CNC machining. 3D printing is one of the manufacturing processes used for rapid prototyping.

3D Printed Prototype Examples

Rapid prototyping with 3D printing can produce models of any shape, size, and material. Examples include simple components such as gears, car or electronic device parts, or even a large-scale model of an architectural structure.

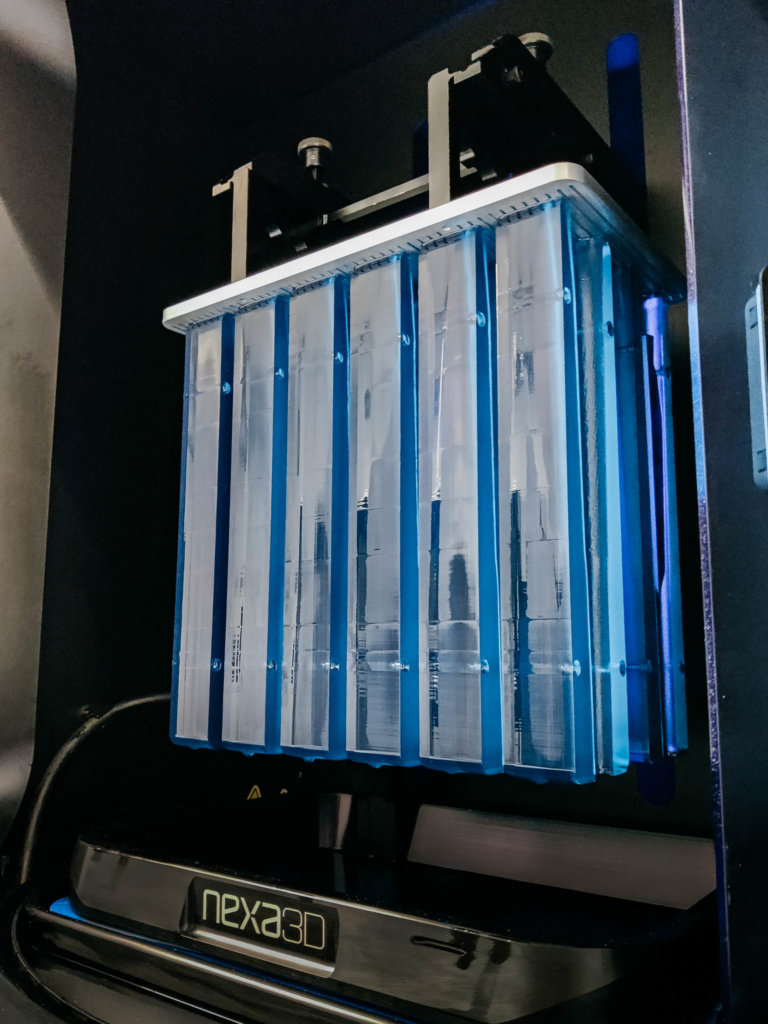

MotoCilino, an engineering service firm, utilizes Nexa3D XiP Desktop 3D printer to accelerate its design iteration and validation process for producing hardware products for various industries such as motorsport, biomedical, consumer electronics, and defense. The XiP’s proprietary technology means it can print with reduced force and achieve next-generation geometries. Through these inverted systems, the manufacturer could primarily focus on complex geometries with an ultrafast print time, flexibility, and precision accuracy.

Wilson Sporting is another perfect example of utilizing rapid prototyping for product development. The company uses Nexa3D and Addifab platforms to churn out new innovations and improve existing product lines.

Although Wilson’s design team started with the traditional subtractive manufacturing methodologies to produce tools for plastic injection mold prototypes, they soon embraced Nexa3D’s Lubricant Sublayer Photo-curing (LSPc®) for improved prototype injection mold tooling and multiple-part production. The firm could reduce costs and time-to-market while still achieving the perfect balance between strength and flexibility in its products.

Wilson Sporting Goods – Printing process

Benefits of Rapid Prototyping with 3D Printing

Time Saving

3D printing technology offers better speed, flexibility, and accuracy compared to traditional manufacturing techniques, especially if using the fastest 3D printing technology. Some 3D printers can take an entire day to produce a prototype model, while other 3D printers, like the Nexa3D XiP, can print at blazing speeds of up to 18 cm per hour– allowing for parts to print up to ten times faster than other leading 3D printers.

This allows designers and engineers to quickly modify designs without waiting for long production cycles. Businesses can reduce the time-to-market as well as minimize the cost and risk associated with developing new products.

Reduced Prototyping Costs

Traditional manufacturing techniques, such as machining or injection molding, can require expensive tooling and molds that can take several weeks or months to make. With 3D printing, there is no need for these costly tools and molds since a 3D printer acts as both a tool and a mold for producing parts. This helps reduce prototyping costs–especially if the prototype is only needed for short-term use or testing.

Rapid prototyping with 3D printers also offers improved part durability because of improved accuracy, and the durability of parts can be achieved by using materials such as nylon, polypropylene, and ABS in a more reliable way. This means that you can make stronger parts faster, allowing for faster end-use product development cycles and a reduction of production waste.

A perfect case study is how Excel Orthodontic Lab tripled its efficiency with the ultrafast NXD 200Pro Dental 3D Printer. The NXD 200Pro cost Excel Orthodontic one-third of the cost of what it was paying for a three-year lease with other Carbon 3D printers. This allowed them to see a significantly higher return on investment and a longer lifetime to build value-added products, including items like twin blocks, splints, and Herbst kits.

Excel Orthodontic x Nexa3D

When building smaller, complex geometries, 3D printing is faster than traditional manufacturing processes. This means it can be used to create multiple iterations of a prototype quickly and accurately. Designers and engineers can test multiple design iterations until obtaining their desired results, allowing businesses to supply new products – and see profits – faster.

Various Iterations and Design Flexibility

3D printing offers designers and engineers the flexibility to quickly make new iterations of a prototype without having to wait for long production cycles or worry about tooling costs. 3D printers can produce multiple versions of a prototype at once, meaning that designs can be quickly tested, evaluated, and modified with just one machine.

They’re also capable of producing complex geometries and details that aren’t achievable with traditional manufacturing methods. Designers can rapidly create innovative products with intricate features and designs, which can lead to greater product success and customer satisfaction.

Other benefits of rapid prototyping with 3D printing include improved accuracy and durability of parts, reduced production waste, and the ability to produce end-use parts.

How to 3D Print Prototypes

1.CAD Design File

CAD software originates from the need to solve complicated manual design problems engineers face during technical hand drawing. Users can customize CAD design files to meet exact specifications, produce complex geometries that are impossible to make manually, and quickly create variations for product development.

2. Slicing Software

The next step in the process is to use slicing software to convert the 3D model into a set of instructions that the 3D printer understands. The slicing software “slices” the 3D model into layers and generates a code that tells the printer where to place each layer and how much material should be used for each layer.

Slicing software is a powerful tool for controlling printing and optimizing print quality. It offers layer-by-layer print previews, customizable supports and rafts, advanced slicing engine settings, 3D model repair tools, and more.

3. The Printing Process

Once the slicing software has generated the code, it can be sent to the 3D printer for printing. The printer then reads the instructions and starts printing according to the code provided by the slicing software.

During the printing process, a nozzle deposits a layer of plastic or other material onto a print bed in small increments until each layer is complete. It’s essential to use high-quality 3D printers to get the best out of the prototypes. The best 3D printers offer greater precision and accuracy, faster print speeds, better layer adhesion and surface finish, and can accommodate a wider range of materials.

Nexa3D 3D printers offer affordable and scalable functional prototyping and on-demand manufacturing solutions for industries such as automotive, aerospace, medical device, consumer electronics, and more.

4. Prototype Testing

After printing the models, it’s important to test them for design and functionality. Testing helps to identify potential product defects, refine designs, and ensure that parts meet specification requirements.

Prototype testing also helps manufacturers determine whether a particular manufacturing process or material works well for their application. This allows them to make necessary changes to their CAD design file or 3D printing process to deliver the best product.

Thanks to the flexibility of rapid prototyping with 3D printing, manufacturers can quickly build parts and test them in a short amount of time. This helps to reduce product development costs, decrease time-to-market, and improve the overall quality of the products.

Use the Best 3D Printer for Prototyping

Rapid prototyping with 3D printing has been proven to be one of the most effective ways to create physical models quickly and cost-effectively. Investment in hard tooling and the financial burden that comes with it can go away. Management teams no longer need to determine how many parts they must produce to justify an investment, worry about the cost of modifying it for a design change, or wonder when it will need replacing.

3D printing prototypes allows businesses and brands to truly think differently about their production process. Of course, selecting the right 3D printer is important. It should allow developers to quickly and accurately test their ideas, improve their designs, and iterate new ones until they reach the best possible product for their customers.

Nexa3D offers an array of ultrafast 3D printers that provide unrivaled throughput, excellent layer adhesion, and consistent print quality. Nexa3D is the perfect solution for professionals looking for a cost-effective way to build prototypes quickly.

Ready to experience rapid prototyping yourself?