- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

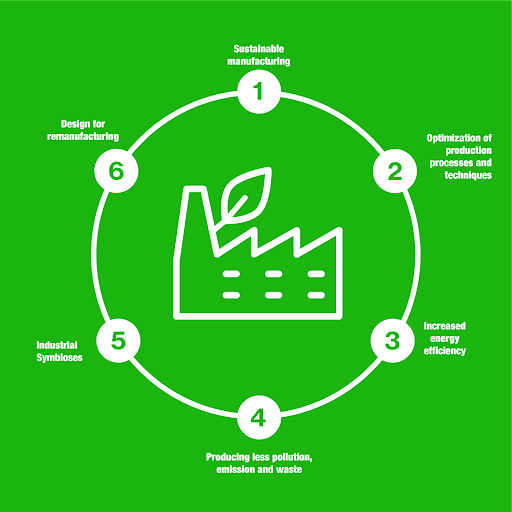

Sustainable manufacturing focuses on creating products through economically-sound processes that minimize negative environmental impact. One primary way companies are looking to achieve sustainable manufacturing is through 3D printing.

3D printing is an additive manufacturing technique that creates three-dimensional objects layer by layer based on computer-aided designs (CAD). This technology is used by multiple industries–including aerospace, healthcare, and manufacturing–to make products faster, more efficiently, and sustainably.

This article will review what sustainable manufacturing is, its benefits, and various methods to implement more sustainable practices into your manufacturing business.

What is Sustainable Manufacturing?

The United States Environmental Protection Agency describes sustainable manufacturing as “the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.”

It involves the adoption of manufacturing practices that balance economic growth with environmental and social well-being.

More manufacturers are starting to recognize the growing demand for “green” practices and are transitioning from traditional manufacturing to sustainable manufacturing. This is because traditional manufacturing processes require large amounts of power, often use wasteful techniques such as milling or cutting, and tend to rely on materials that aren’t eco-friendly.

Sustainable manufacturing embraces production techniques that focus on reducing waste, pollution, and toxic emissions–all to keep the planet and its inhabitants safe.

Sustainable Manufacturing Benefits

Reduced Waste & Energy Consumption

Traditional manufacturing processes often result in copious amounts of waste materials, including excess raw materials, packaging, and byproducts. American industries generate and dispose of an estimated 7.6 billion tons of industrial solid waste each year. This waste not only burdens landfills but also contributes to pollution and resource depletion. Sustainable manufacturing, on the other hand, employs strategies such as lean production and circular economy principles to minimize waste at every stage of production.

Non-renewable energy makes up nearly 90% of the global energy supply, which is depleting due to the unsustainable practices adopted in industrial manufacturing. This resource depletion not only increases overhead operating costs but also contributes to environmental degradation.

Sustainable manufacturing solves this problem by integrating energy-efficient technologies throughout the production process. For example, to make wind turbines more efficient at capturing wind energy, researchers at the US National Renewable Energy Laboratory have developed a way to 3D print wind turbine blades using thermoplastics. This method creates advanced blades that are lighter, longer, less expensive, and more efficient.

Cost Effectiveness

Companies can reduce operational costs related to utilities and raw materials by implementing energy-efficient technologies and optimizing resource usage.

Additionally, waste recycling practices promoted in sustainable manufacturing reduce the expenses that come with purchasing and disposing of materials. This, together with sustainable supply chain management and locally sourcing materials, helps to reduce transportation costs and create long-term cost-reduction benefits.

Also, the U.S. government acknowledges the importance of sustainable and renewable energy and has implemented measures to encourage businesses to adopt green practices. To support this approach, businesses are eligible for various tax advantages that serve as incentives. These incentives include tax breaks, rebates, and other financial rewards, which are available at both the state and federal levels. Here are some examples:

- Business deductions: Businesses can claim deductions for the installation of energy-efficient systems such as HVAC, interior lighting, or hot water systems, which significantly reduce power consumption.

- Tax credits and grants: Businesses can benefit from tax credits and grants of 10 to 30 percent for the utilization of alternative energy properties. These incentives encourage the use of renewable energy sources and technologies.

- Bonus depreciation: Qualified recycling and reuse of certain equipment or machinery can be eligible for bonus depreciation. This provides additional tax benefits to businesses engaged in environmentally responsible practices.

These tax advantages aim to incentivize businesses to embrace sustainable practices, reduce their carbon footprint, and contribute to the transition toward a greener economy.

Innovation Opportunities

Sustainability goals can change how essential resources are used in product creation and processing. This often leads to the development of innovative, eco-friendly designs, materials, and manufacturing techniques.

Companies may explore the use of renewable materials, implement energy-efficient production methods, or create products with improved durability and recyclability. These innovations not only reduce environmental impact but can also lead to enhanced product performance and customer satisfaction.

Improved Competitiveness

According to a study on corporate social responsibility, 88% of consumers will be more loyal to a company that supports social or environmental issues. To improve brand image and demonstrate a commitment to the health of the planet, organizations are working to offer greener solutions.

Companies that adopt sustainable manufacturing strategies can gain a competitive edge, attracting eco-conscious customers and establishing themselves as industry leaders.

Methods to Improve Sustainable Manufacturing

There are several opportunities organizations can take to make their manufacturing processes more sustainable.

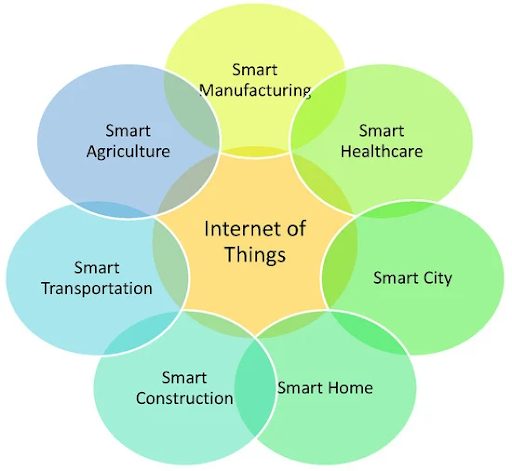

1. Use Digital Technology & Automation

Digital technologies enable the collection and analysis of vast amounts of data throughout the manufacturing process. By leveraging data analytics, manufacturers can gain valuable insights into their operations, energy consumption, material usage, and waste generation. This data-driven approach allows for informed decision-making to optimize resource utilization, identify areas for improvement, and implement more sustainable practices.

Automation systems integrated with digital technology can monitor equipment and machinery in real time. This enables predictive maintenance, where potential failures or inefficiencies can be detected early, reducing downtime and minimizing energy waste. Additionally, digital technology facilitates energy management by providing visibility into energy consumption patterns, allowing manufacturers to identify and implement energy-saving measures.

Digital technology and automation enable the creation of interconnected and intelligent supply chain networks. Real-time data sharing and communication between suppliers, manufacturers, and customers improve inventory management, demand forecasting, and production planning. This reduces waste associated with overproduction, excess inventory, and inefficient logistics, resulting in a more sustainable and streamlined supply chain.

2. Reduce Subtractive Manufacturing Practices

Subtractive manufacturing is a manufacturing process that involves removing material from a solid block or stock to create a desired shape or product. It involves tools and techniques such as cutting, milling, turning, drilling, or grinding. Unlike traditional manufacturing processes that often involve cutting away excess material from a larger block, 3D printing utilizes an additive approach.

This means that objects are built layer by layer, adding material only where it is needed. This method minimizes material waste since the printer uses only the necessary amount of material to create the desired object. For instance, when creating an engine part prototype, 3D printing requires significantly less material compared to machining it from a solid block of metal.

The U.S. Department of Energy estimates that (compared to traditional manufacturing) 3D printing might slash waste and materials costs by nearly 90% and cut manufacturing energy use in half.

3. Reduce Emissions & Pollution

Nearly 30 percent of U.S. greenhouse gas emissions come from industries, including indirect emissions from the sector’s electricity consumption.

To create a sustainable environment, manufacturers need to adopt practices that drastically reduce the number of emissions and pollution created, including switching to lower-emitting fuels, such as decarbonized gas, utilizing renewable energy, recycling materials, and practicing additive manufacturing processes. This is especially important because industrial waste is a landfill liability that contaminates the environment, degrading many important ecosystems

4. Prioritize Local Resources

Many manufacturing supply chains begin with sourcing materials from long distances and transporting them back for on-site processing. However, this process of transporting materials via road, air, or sea contributes to noxious emissions and energy waste that is harmful to the environment.

Prioritizing local resources means sourcing production materials within one’s vicinity. By sourcing materials and resources locally, manufacturers can reduce the carbon footprint associated with transportation and logistics, as shorter distances lead to lower emissions.

More importantly, sourcing materials locally also offers companies the chance to control their supply chain and the overhead costs of production.

Reduce, Reuse, Recycle

The “reduce, reuse, and recycle” approach is crucial for sustainable manufacturing due to its ability to conserve raw materials and minimize environmental impact. Let’s explore how these principles can be applied specifically to 3D printing:

- Reduce: 3D printing enables manufacturers to reduce various aspects of the production process. It allows for the reduction of materials needed by optimizing designs and minimizing waste. Through precise control of the printing process, manufacturers can use only the necessary amount of material, minimizing excess and reducing overall material consumption.

- Reuse: This means to use materials that have already been used once, such as by printing new objects with leftover filament or by repurposing supports that were used to print a part. Reusing materials helps to reduce the amount of waste that goes to landfills or incinerators.

- Recycling: This means breaking down materials into their component parts and then using those parts to create new products. Recycling can help to conserve natural resources and reduce pollution.

In 3D printing, both reuse and recycling can be used to reduce waste. However, there are some important differences between the two practices.

- Reuse is typically simpler and less energy-intensive than recycling. This is because reused materials do not need to be processed or transported, which can save energy and resources.

- Recycling can create new products that are different from the original product. This can be a benefit if the new product is more valuable or useful than the original product.

In general, reuse is the preferred option for reducing waste in 3D printing. However, recycling can be a good option if the reused materials cannot be used for another purpose.

How 3D Printing Can Support Sustainable Production

As the world becomes increasingly aware of the need for sustainable practices, 3D printing is well-positioned to play a major role in the future of manufacturing. Here are some ways 3D printing contributes to sustainable manufacturing practices.

On-demand Manufacturing

On-demand manufacturing, also known as custom manufacturing or digital manufacturing, is a production approach that focuses on producing goods in response to specific customer orders, rather than producing in bulk and holding inventory.

In traditional manufacturing, companies typically forecast demand, produce goods in large quantities, and store them in warehouses until they are needed. This approach carries the risk of overproduction, inventory obsolescence, high carrying costs–and therefore wasted products and lost investments.

On-demand manufacturing offers a more streamlined and responsive method by only creating products when they’re needed. However, to do this successfully, manufacturers need high-quality production processes that can still create parts quickly.

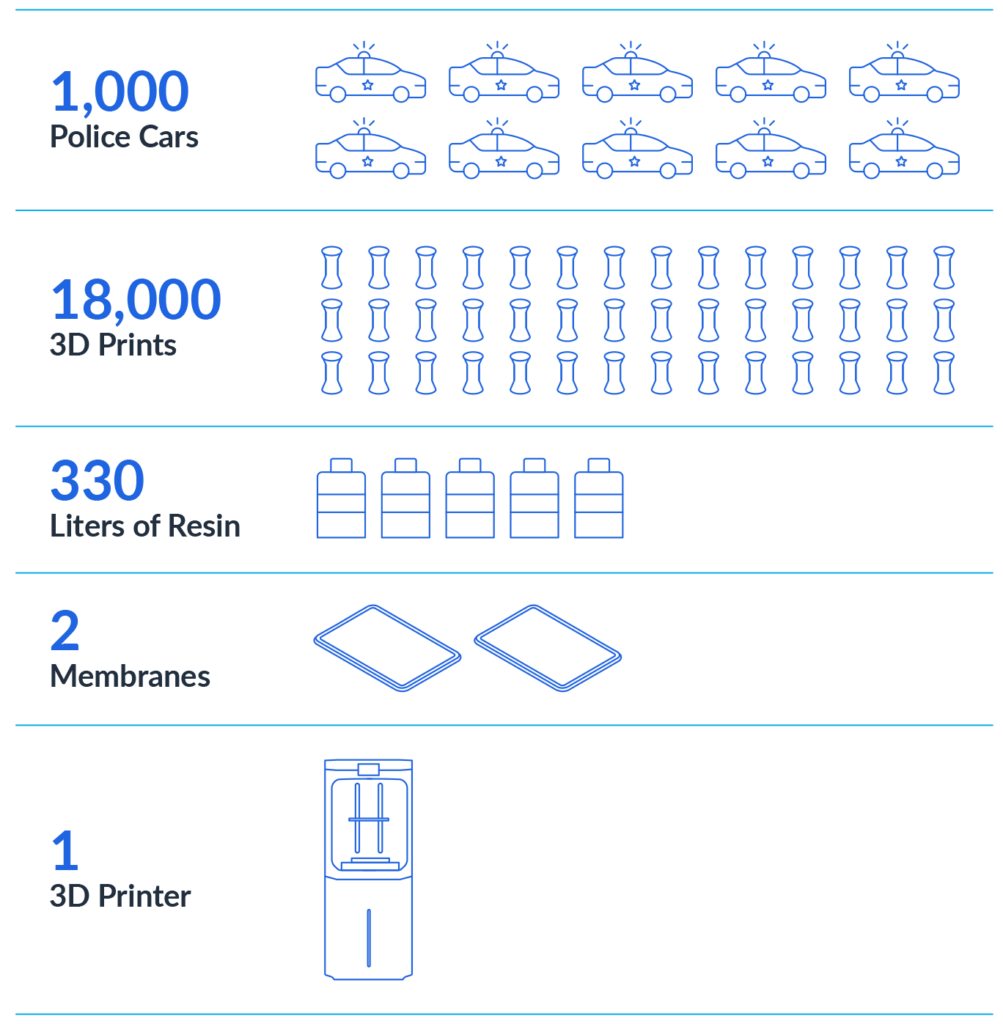

3D printing enables the production of highly customized products on demand. An example of this can be seen when Stellantis posted a bid for the design and manufacture of aftermarket components for 400 police cars for the French Gendarmerie. The vendor would have only three months to turn around 7200 components (18 individual components for each of the 400 vehicles). Not a lot of time because these parts had to be custom designed from scratch.

But R3D was able to achieve the initial run of 7200 components well within the 3-month timeline with the help of Nexa3D. Something that would not have been possible with traditional manufacturing. The reception was so positive that two additional orders for 12,600 parts for 700 additional vehicles were placed and R3D delivered flawlessly.

Nexa3D x R3D

Reduced Waste

3D printing generates an average of 70-90% less waste than traditional subtractive manufacturing processes. Many 3D printing materials are eco-friendly, like the filament PLA which is made from cornstarch or sugarcane and is biodegradable and compostable.

3D printers like the Nexa3D QLS 230 and QLS 236 use thermoplastic materials that can be melted and reused multiple times. This allows for the recycling and reusability of materials, reducing the consumption of resources and diverting waste from landfills.

3D printing also enables design optimization. With this technology, designers can confirm whether a design works as intended, identify potential flaws or improvements, and make necessary adjustments without requiring a substantial amount of energy or materials. Instead of manufacturing multiple physical prototypes using traditional methods, which can be time-consuming and wasteful, 3D printing allows for rapid iterations at a fraction of the cost and resource consumption.

Fewer Emissions During Production

With traditional manufacturing processes, large amounts of energy are often used for production, leading to higher levels of CO2 and other emissions. Alternatively, most 3D printers produce fewer emissions and require fewer raw materials–and therefore less energy to procure and transport those materials.

Printing parts locally and on-demand further reduces carbon emissions typically associated with the transportation of goods from the point of manufacturing to the point of use.

Improved Production Efficiency

3D printing boosts production efficiency through rapid prototyping, enabling quick iterations, and accelerating the product development cycle.

3D printing also enables the creation of products in-house and locally. This eliminates the need for outsourcing or relying on external suppliers, reducing lead times and dependency on third-party production schedules. By bringing the manufacturing process in-house, businesses gain greater control over their production timelines and can respond quickly to changes in demand or design iterations.

This direct control over production reduces bottlenecks, optimizes supply chains, and ultimately improves overall production efficiency.

Sustainable 3D Printers

Although 3D printing is a more sustainable substitute for traditional manufacturing, not all 3D printers are considered sustainable.

Sustainable 3D printers typically employ eco-friendly materials to reduce their environmental impact. They also incorporate energy-saving features, like low-power consumption or sleep modes, to minimize energy usage and reduce toxic emissions.

Let’s take a look at some of the most sustainable 3D printers.

1. QLS 820

Nexa3D QLS 820 thermoplastic 3D printer is a quad laser system with unprecedented production capabilities designed with automation and scalability. It has the highest part throughput in its class, and offers print speeds of up to 8L per hour and an average packing density of 20%, delivering up to 4x productivity gains over other powder-based polymer 3D printing systems.

The QLS 820 has an open-source platform that allows for printing many materials, including PA12, PA11, and Polypropylene, as well as aluminum, glass, and fiber-filled options.

With the QLS 820, manufacturers such as JawsTec were able to eliminate sintering powder waste while lowering the waste ratio of sintering powders used, which in turn enhanced company sustainability and streamlined costs. With QLS 820, the company could utilize 100% of its powders, which was impossible with their older systems that were running a 50% new powder refresh rate. As a result, JawsTec was able to reduce the wastage of end-of-life powder and raise SLS manufacturing output by 50% due to the platform’s shorter printing cycles.

2. QLS 230 & QLS 236

Nexa3D QLS 236

Nexa3D’s QLS 230 and QLS 236 are the most affordable open-platform selective laser sintering (SLS) 3D printers for industrial use. They offer cutting-edge productivity and rapid printing, with the QLS 230 boasting a 24-hour cycle speed and the QLS 236 offering an unrivaled 21-hour cycle speed.

When it comes to sustainability, the QLS 230 & 236 printers are most notable for their material flexibility and open-source platform that permits the use of recycled powders from HP® and EOS. By recycling unused materials from previous prints, the QLS 230 & 236 printers facilitate material usage efficiency while reducing waste.

The QLS 230 and 236 exemplify sustainability at every stage by incorporating a range of eco-friendly features to minimize their environmental impact optimizing resource utilization.

Nexa3D QLS 230

The CEO of JawsTech, Oscar Klassen, explains: “Our QLS 230 SLS printers offer something others do not, the ability to use end-of-life powder from our EOS and HP MJF machines for high-quality SLS parts. On top of the operational sustainability, the smaller build volume of the QLS 230 allows for a 22 hour complete build cycle that only requires a 2-hour cooling cycle with zero negative effect on part accuracy or surface quality.

The adoption of the smaller platform for high daily throughput is a game changer. We have options for an expedited two business day turn-around in our 3D Printing Service.”

Learn more about QLS 236 and QLS 230

3. XiP Pro

Nexa3D XiP Pro is the world’s fastest industrial 3D printer. The XiP Pro 3D printer delivers the highest production throughput at the lowest cost of operation. At 19.5L, the XiP Pro offers the largest build volume and fastest print speed in its class–and its unrivaled productivity allows you to produce functional prototypes and production parts at previously unattainable economics.

XiP Pro is an open platform printer and can support reduced manufacturing waste by using its open material platform to print in a variety of resins that meet manufacturing specifications without excess inventory. Whether you’re looking to build quick models in clear resins, prototype functional parts in engineering materials, or produce end-use components and 3D-printed molds using heat-resistant resins, like xPEEK, xCERAMIC, or xMOLD you’ll find that XiP Pro is the most versatile industrial 3D printer on the market.

“XiP Pro gives us about 10x the throughput of what we had before. Nexa3D has done a really great job taking the costs out of 3D printing while increasing the capacity. Their printers are getting bigger, faster and more affordable at the same time. It’s a total win for the users.”

Glen Mason

DeMarini Sports / Wilson Sporting Goods

Improve Your Sustainable Manufacturing Practices

The future of sustainable manufacturing is bright, and 3D printing is playing a leading role. As the technology continues to develop, we can expect to see even more innovative and sustainable applications for 3D printing in the years to come.

3D printing can be used to achieve sustainability in manufacturing by:

- Reducing waste: 3D printing only uses the material that is needed to create a part, which can help to reduce waste by up to 90% compared to traditional manufacturing methods.

- Conserving resources: 3D printing can be used to create parts from recycled materials, which can help to conserve natural resources.

- Supporting local production: 3D printing can be used to produce parts locally, which can reduce the need for long-distance transportation and the associated emissions.

To fully improve your sustainable manufacturing practices, it is important to use 3D printers that prioritize sustainable manufacturing

At Nexa3D, we believe in the power of an abundant material ecosystem–our 3D printers have been designed to reduce manufacturing waste by using an open material platform, operational sustainability, and recycled materials. We also continue to partner with leading material providers to deliver a comprehensive range of high-performance functional materials that are tailored to your needs.

Are you ready to experience sustainable manufacturing?