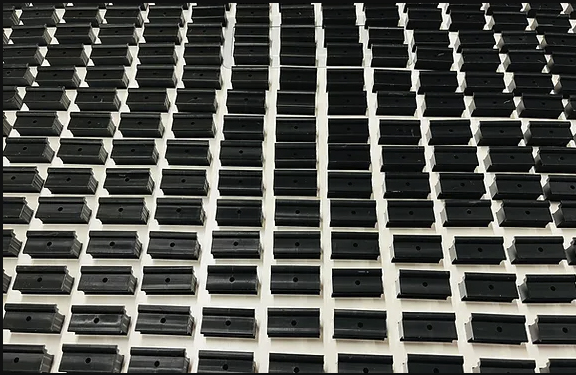

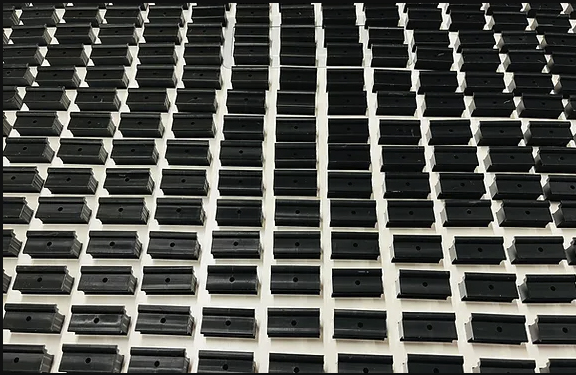

MaxResolution3D and FormFoundation Case Study

By utilizing NXE 400Pro 3D printers MaxResolution3D was able to design, print and deliver 500 parts to FormFoundation in just 5 days.

View Case Study

By utilizing NXE 400Pro 3D printers MaxResolution3D was able to design, print and deliver 500 parts to FormFoundation in just 5 days.

View Case Study

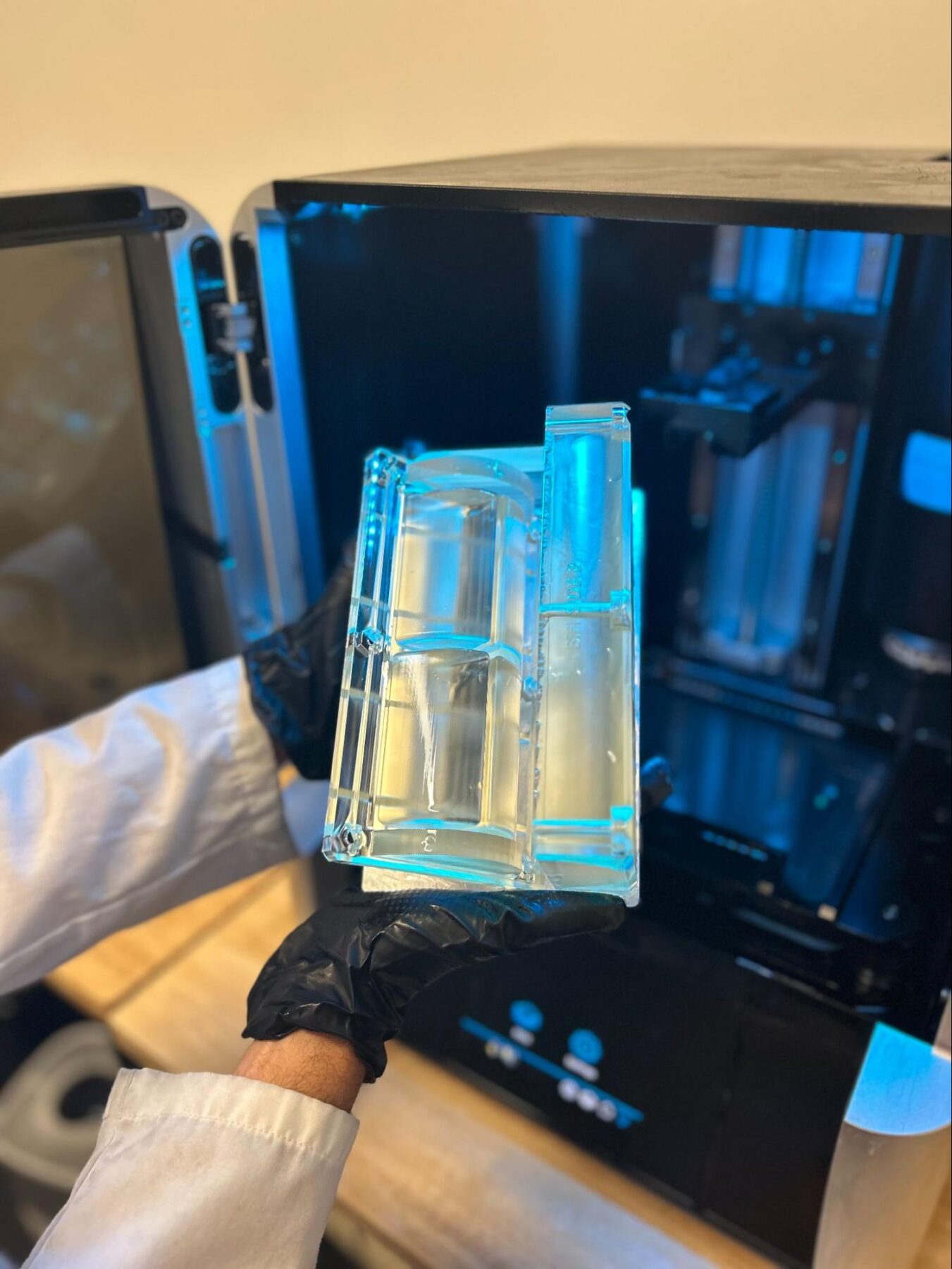

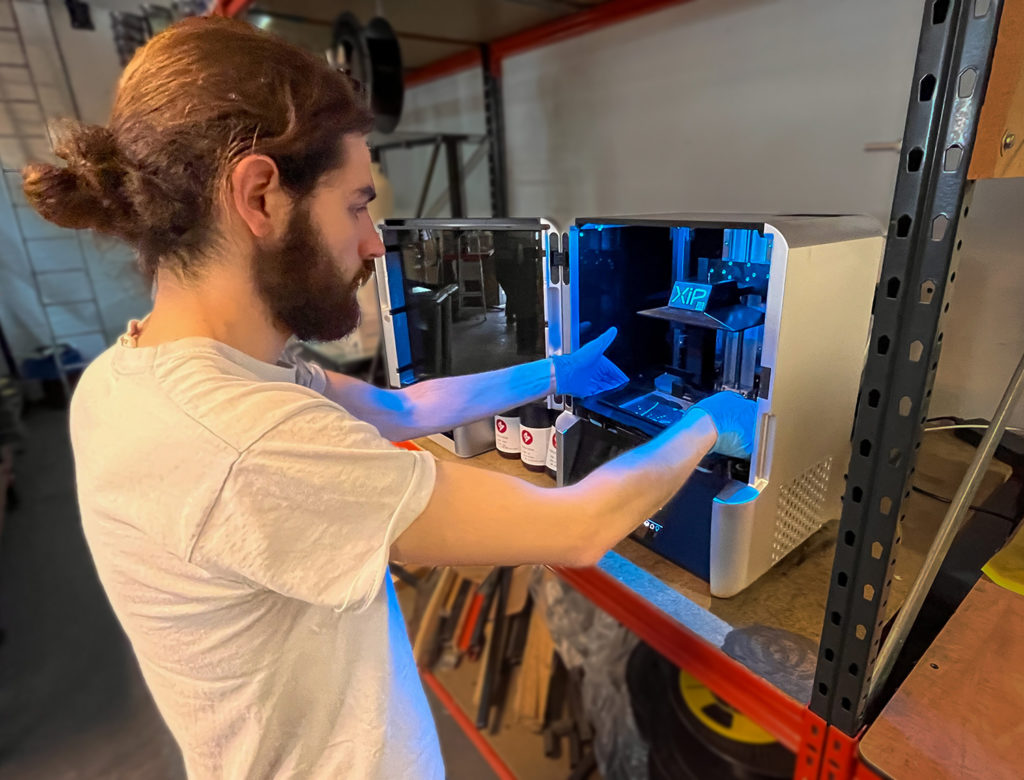

By adopting the freeform injection molding (FIM) process using Nexa3D’s XiP desktop 3D printer and xMOLD material, Alpine Advanced reduced production costs by as much as 86% and lead time by as much as 91%.

View Case Study

Yawman Flight collaborated with MotoCilino Engineering Service firm to develop a unique controller in record time, going through 17 different design iterations before validating the final assembly in just a few weeks. The final prototype controller consists of 36 different components, all of which were printed on the XiP desktop 3D printer using xABS3843 high performance resin.

View Case Study

Using fast printing XiP, the Gentle Giant team swiftly iterated designs and gained Disney’s approval within 48 hours.

View Case Study

Combining a seamless impression-capturing process with the speed and open material platform of XiP Desktop 3D Printer unlocks mass customization opportunities for a medical device startup.

View Case Study

JawsTec chose QLS SLS 3D Printers by Nexa3D to eliminate powder waste while dramatically increasing machine throughput and uptime.

View Case Study

New solutions like XiP allow MTB3D to produce pristine parts with unmatched throughput opening the door to new customer industries and applications.

View Case Study

In one year, R3D used their single NXE 400 3D printer to manufacture 18,000 parts for 1,000 police cars. They used over 330 liters of resin during the process, but only two Everlast 2 Membranes (the main wear consumable of the NXE 400).

View Case Study

Learn how Alstom extends the life of their high-speed rail cars with 3D printed replacement parts.

View Case Study