PepsiCo Case Study

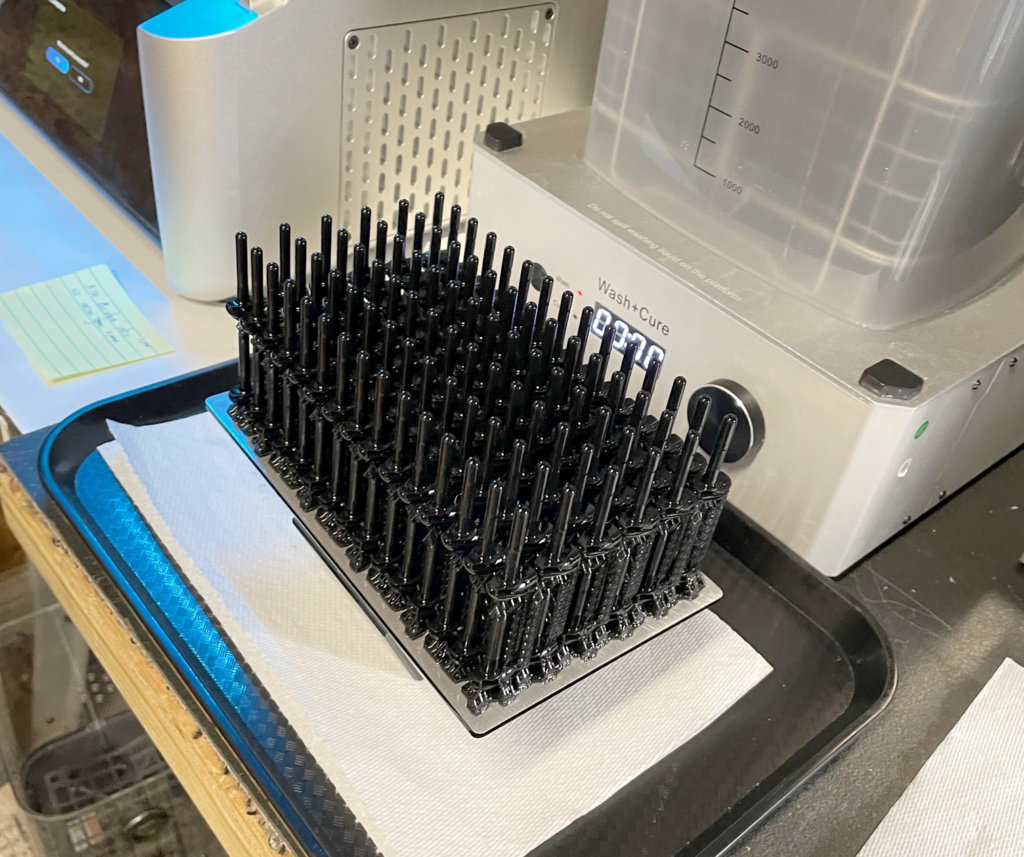

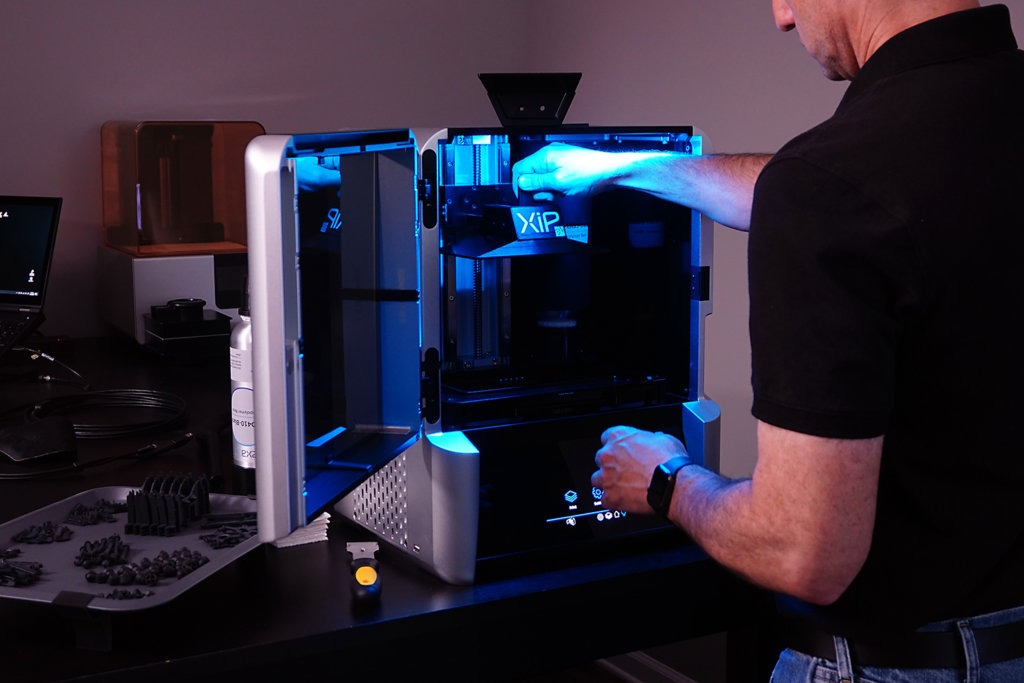

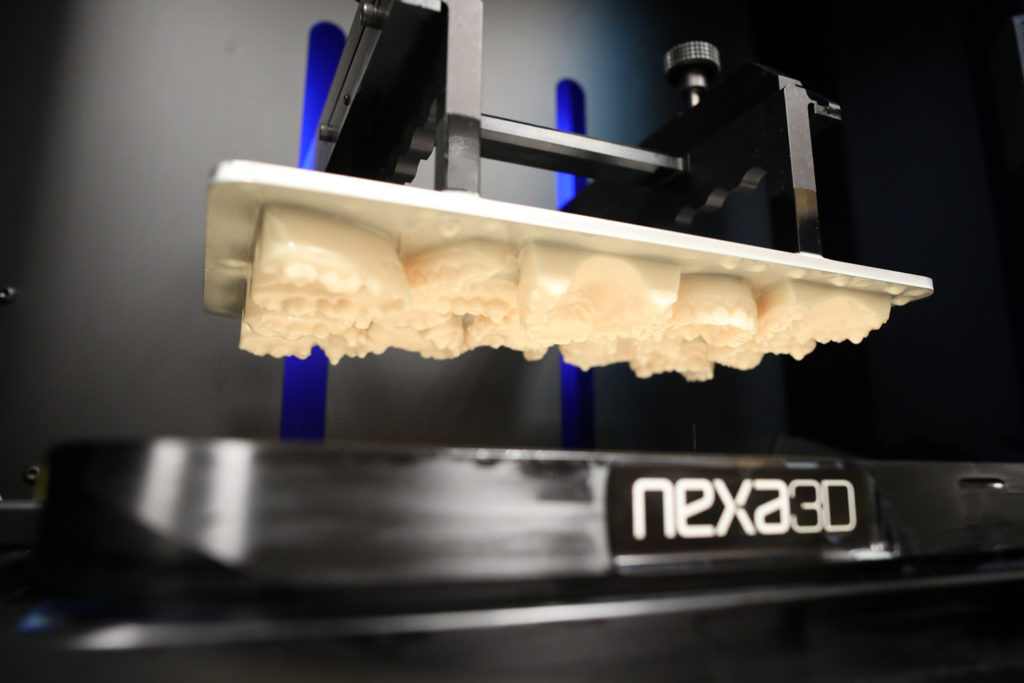

PepsiCo’s patented hybrid-made molds made on NXE 400 industrial 3D printer can be successfully used for more than 10,000 bottles before failure at up to a 96% reduction of cost compared to traditional metal tooling.

View Case Study