Wilson Case Study

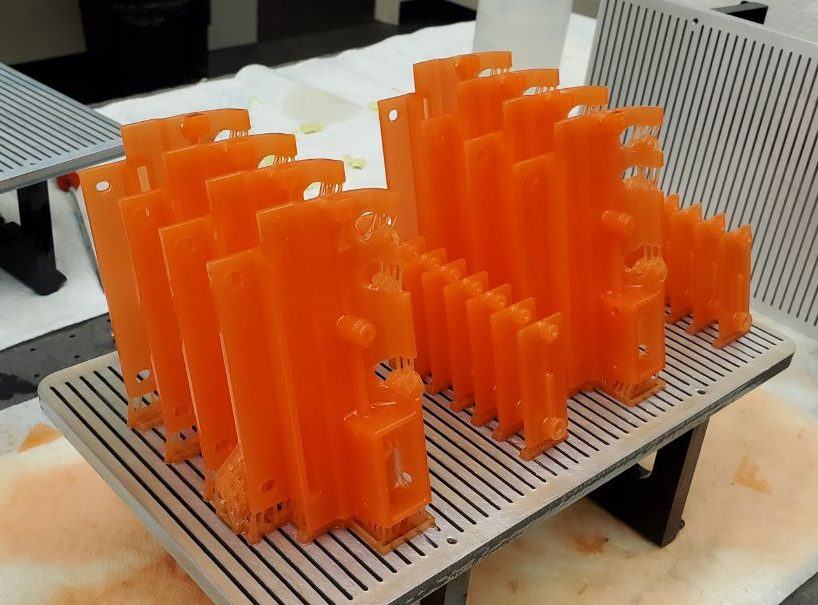

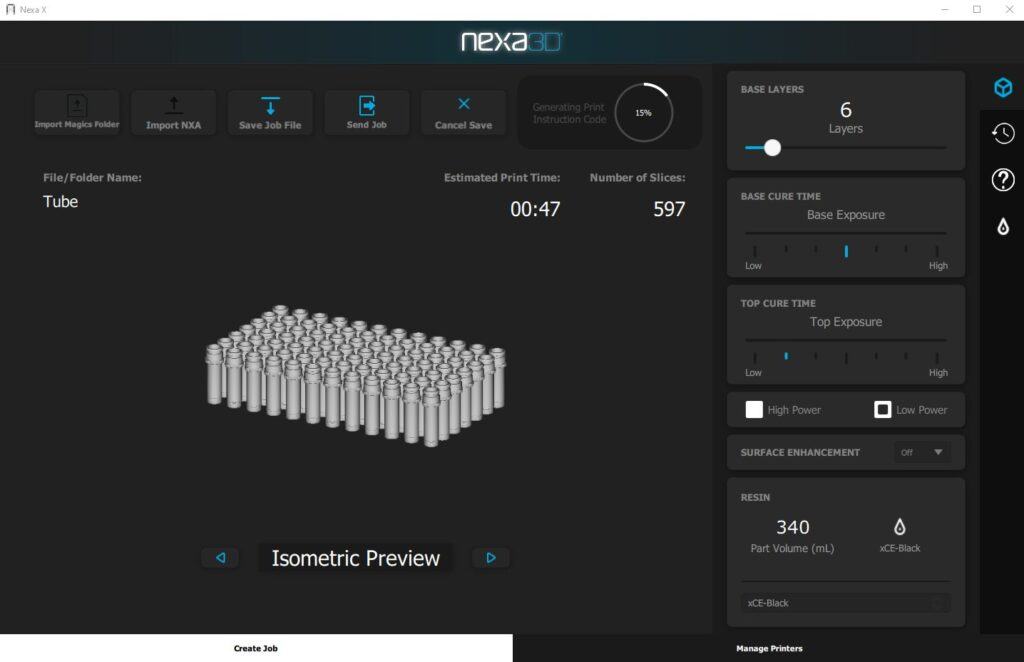

With Nexa3D’s large print envelope and ultrafast LSPc process, the Wilson R&D group can now produce multiple parts at once, in a rapid manner, allowing for multiple design iterations in a single print batch.

View Case Study

With Nexa3D’s large print envelope and ultrafast LSPc process, the Wilson R&D group can now produce multiple parts at once, in a rapid manner, allowing for multiple design iterations in a single print batch.

View Case Study

By investing in an ultrafast production-focused system with a larger build plate, the team quickly found they were decreasing design and production costs while increasing output and quality.

View Case Study

When starting a company, ensuring the right product, processes, and market fit that can adequately be served is just part of the overall equation. For the MaxResolution3D team, having a 3D printing system they could grow and scale with was essential to starting off on the right foot.

View Case Study

When traditional 3D printing technology failed to keep pace with the production speed of machine building business VUTS, the company turned to long-time partner Industrial Technology Systems s.r.o to find the answer.

View Case Study

With depleting supplies of personal protection equipment (PPE) for front line workers during COVID-19 pandemic, the demand on supply grew sharply, resulting in significantly longer lead times and price increases. Henkel/LOCTITE and Nexa3D worked fast to meet the demand for face shields.

View Case Study

HAUX-LIFE-SUPPORTdemands outstanding technical performance, innovation, quality and reliability because their life-saving equipment can’t fail. They trusted the NXE 400 because of its ability to deliver the quality and tolerances the product demands.

View Case Study

Growing up around traditional manufacturing, the founder of Optomiz3D knew that there was potential for a business that joined the best of both worlds— that vision was realized with the NXE 400.

View Case Study

FLYER has a history of innovation in the e-bike category, so 3D printing was a natural addition to the design process.

View Case Study

As one of the most trusted open-source resin suppliers in the industry, Keystone partners with 3D printer manufacturers, rigorously validating each printer to ensure it meets the necessary accuracy and quality parameters. Nexa3D’s NXD 200 not only met Keystone’s criteria–it provided a game-changing option for the dental industry.

View Case Study