- Metal 3D Printing Guide: What It Is & How It Works [2024] - February 5, 2024

- Metal Injection Molding: What It Is & Top Alternatives [2024] - January 11, 2024

- 11 Fastest 3D Printers on the Market (Industrial and Desktop) [2023] - December 11, 2023

Powder bed fusion is a type of additive manufacturing that involves melting or sintering layers of powdered material using a heat source to create a finished product.

Powder bed fusion, like other 3D printing processes, is helping transform industrial manufacturing by providing the ability to accurately create intricate designs that are otherwise unachievable using traditional manufacturing. However, as with any manufacturing process, the accuracy and precision of a powder bed fusion process depend on the choice of PBF 3D printer.

This detailed guide will explore the fundamentals of powder bed fusion technology and highlight some of the best 3D printers sold in the market today.

What is Powder Bed Fusion?

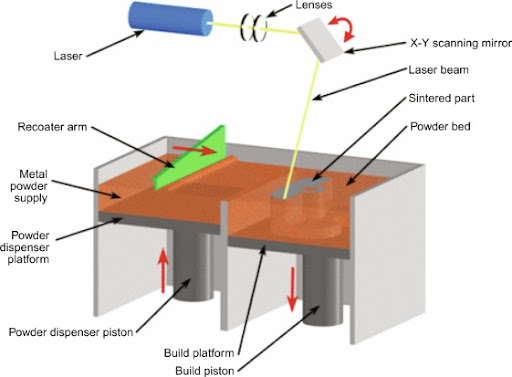

Powder bed fusion is a collection of additive manufacturing processes that fuse powdered materials to create a solid object with a laser, thermal energy, or electron beam. The heat source’s path is determined at each layer by near-accurate calculation to define the structure’s contour, thereby mapping a fusing sequence or raster pattern.

Powder bed fusion is favored for its ability to produce complex geometries with high levels of detail and accuracy. It’s used across multiple industries to create automotive and aerospace parts, personal protective equipment, HVAC components, shoe insoles, eyewear, and much more.

The Powder Bed Fusion Process

The powder bed fusion process begins with creating a 3D CAD file, which is the design template or model for the object the manufacturer wishes to print.

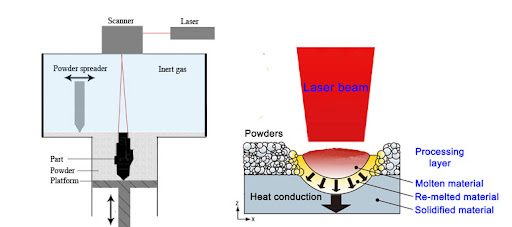

After the 3D CAD file is created, a thin layer of powder is spread evenly across the building platform at the beginning of the process. The particles are selectively melted to a desired pattern as the laser or beam is directed to the powder bed. When one distinct layer is completed, the build platform shifts downward by one layer thickness, then proceeds with the sintering and fusing of a new layer. Every layer is then bonded to each other sequentially and uniformly until the complete object is formed.

All PBF processes have a lengthy post-print cooldown cycle before the breakout and depowdering steps. Factors influencing the cooldown period include build time, packing density, material, and cooling method.

After the cooldown, parts are extracted from the surrounding powder, which is often called breakout. The remaining unfused material is then processed for reuse via a bunch of processes that begin with sieving and end with mixing. After PBF parts have been extracted and depowdered, they move into post-processing to enhance aesthetic qualities, modify features, or augment functionality.

Laser-Based vs. Binder-Based Powder Bed Fusion

Laser-based PBF processes like selective laser sintering utilize high-power lasers to selectively fuse polymer powder particles to form solid objects while binder-based PBF uses a liquid binder to selectively bond together layers of metal powder to form a part.

Binder-based PBF uses a computer-controlled system that sketches out the contour of each layer of the structure being created and directs the dispensing of the binder onto the metal powder layer by layer. After the part is finished, it’s taken out of the powder bed and put in an oven to remove the binder and sinter the metal powder into a solid part. Multi-jet fusion is an example of binder-based Powder Bed Fusion 3D printing.

Deciding which sub-category of PBF technology to adopt in your manufacturing process can be challenging. To help, we have curated a detailed, tested, and trusted guide to make the decision process easier and determine which is the right one for you.

Read More: SLS vs. HSS—Which AM Plastic Powder Bed Fusion Technology is Best for You?

Powder Bed Fusion 3D Printing Processes

Different types of PBF processes vary by the heat source and material being used.

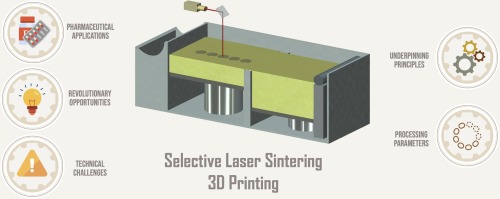

Selective Laser Sintering

SLS also called Laser Sintering (LS) or Laser Powder Bed Fusion (L-PBF), uses a laser to deliver thermal energy to the powder bed to sinter polymer powder particles (such as nylon and polyetherketoneketone or PEKK). Like the typical PBF process, the SLS machine fuses each layer starting from the bottom part, with the build platform lowering continuously to move from one layer to the other. As the particles are heated, the layers fuse to form one whole shape.

Pros:

- Less wastage since unused powder can be recycled

- Support-free structure for optimal geometrical freedom

- Provides access to a richer set of build parameters to refine part characteristics

- Provides visibility into process parameters and build data for tuning builds and providing process traceability

- The ability to create end-use parts due to the strength and versatility of thermoplastics.

Cons:

- Complex technology

- Not suitable for hobbyists

SLS 3D Printers:

- Nexa3D QLS 230: QLS 230 is the most affordable and professional SLS printer suitable for large-scale manufacturing processes. It offers a 24-hour building cycle with a 2-hour cooling window that uses a single 30 Watt CO2 laser to increase your daily throughput without the need for a lengthy cooling period due to its smaller build chamber. QLS 230 has an open platform with 10+ qualified nylon and metal fusion materials. It also excels with recycled powders from HP and EOS for ultimate operational sustainability. QLS 230 is powered by two advanced software suites, Buildware, and XYZprint AMSLS. Buildware controls the sintering process while the XYZprint AMSLS allows users to start and monitor jobs remotely.

- Nexa3D QLS 236: QLS 236 is another open platform SLS 3D printer with an unrivaled 21-hour cycle speed. QLS 236 is a productivity powerhouse and uses a single 60 Watt CO2 laser to increase daily throughput without the need for a lengthy cooling period due to its smaller build chamber.The QLS 236 also has over 16 qualified materials, including a range of Polyamides, PP, PBT, TPU, as well as patented metal powders. It uses recycled powder from HP and EOs, thereby offering operational sustainability.

- Nexa3D QLS 820: The QLS 820 has industry leading production throughput, producing up to 4x the output of traditional laser sintering 3D printers and other polymer powder bed technologies. It is a quad laser system offering unprecedented production capabilities designed with automation and scalability. The QLS 820 can also print up to 8 liters per hour at 20% job density and is designed to be scaled for production.

Selective Laser Melting

Selective Laser Melting, or SLM, is used for metal 3D printing during which a high-density laser beam welds metal particles together. Instead of sintering the particles like in SLS processes, the laser fully melting the powder creates a structure with more strength and fewer voids. SLM is used for aluminum alloys, titanium and its alloys, stainless steel, and exotic metals such as tungsten.

Pros:

- Metal parts are very strong

- Creations are precise and accurate to the smallest detail

- No restriction to the geometry of the creation

- Shorter assembly times

- A high mechanical load capacity

- Wide range of materials to choose from

Cons:

- An inert gas supply is required to prevent oxidation during the manufacturing process

- Higher cost of entry

- Metal materials can be expensive

SLM 3D Printers:

- 3D Systems Pro X DMP 320: It uses a technology known as Direct Metal Printing to build parts up to 275 x 275 x 420 mm in volume.

- EOS M 400: This SLM printer uses a 1 kW ytterbium laser to melt and fuse powder using modular construction processes.

- SLM 125: It has a build volume of 125 x 125 x 125 mm, which is scalable to 50 x 50 x 50 mm. It is equipped with a single 400 Watts fiber laser and can be used in industrial settings.

Direct Metal Laser Sintering

Direct Metal Laser Sintering, or DMLS, might be a misnomer because full melting, not sintering, is achieved during the manufacturing process. Compared to SLS, DMLS can be up to 95% dense steel parts with a higher resolution and thinner layers. Materials commonly used during DMLS are aluminum, bronze, cobalt-chrome, titanium, alloy steel, stainless steel, and tool steel.

DMLS is a relatively new 3D printing solution, having only been used commercially since 1995.

Pros:

- A wide range of metal materials to choose from

- Utilization of DMP processes

- Production of highly durable and extremely strong functional parts

- Absence of a support structure leading to dimension and design accuracy

- Ability to reuse unsintered metal after production

Cons:

- Printers are on the high end

- Materials are expensive to purchase

- Production of porous parts as porosity cannot be eliminated after the printing process

- A small build volume

- A slower printing speed than other 3D printing processes

DMLS 3D Printers:

- ProX 100: This is an entry-point DMLS printer with a build capacity of 100 x 100 x 100 mm. It works with a surface quality finish of up to 5 Ra μm (200 Ra micro-inches)

- ProX 320: Has a build volume of 275 x 275 x 420 mm and bi-directional powder deposition

High-Speed Sintering

In this raster-style printing method, the build platform is heated by an infrared (IR) heating element that sweeps across the powder bed. A thin layer of plastic material is added to the heated platform, and a jetting pass deposits fluid on the plastic material to facilitate IR energy absorption, causing it to melt and fuse.

Pros:

- Faster creation of multiple small to medium end-use parts

- High throughput

- High accuracy makes it a more effective option than injection molding.

Cons:

- More expensive than many other 3D printers

- Complex printing process

- Limited materials to choose from

- It can only produce smaller parts.

HSS 3D Printers:

- VX1000 HSS: Has a working volume of 1000 mm x 540 mm x 400 mm, which can make it a good option for medium-sized jobs.

Selective Absorption Fusion

Selective Absorption Fusion (SAF)is a type of HSS printing method. It’s a polymer PBF process that utilizes industrial-grade piezo-electric printheads, a type of inkjet printer that uses electric current to force ink into a substrate. The printheads jet high absorption fluid (HAF) on a polymer powder bed to fuse the powder into a 3D-printed object.

Pro:

- Make plastic parts with high longevity and durability

- Bulk production of components due to high throughput

Cons:

- Polymer-only process

- Risk of loose powder being encapsulated in the 3D-printed components

SAF 3D Printers:

- Stratasys H350: This 3d printer is powered by Selective Absorption Fusion (SAF) technology. The H350 utilizes the Big Wave™ powder management system and has a build envelope of 315 x 208 x 293mm.

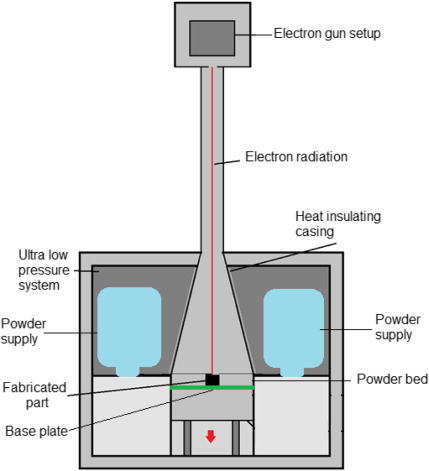

Electron Beam Melting

Electron Beam Melting is a 3D printing process that uses a high-energy electron beam to melt powdered metal. The beam creates a stream of electrons that are guided by a magnetic field and is used to melt powder material into a precise creation defined by a CAD model. The process is executed in a vacuum chamber to prevent the possibility of oxidation of highly reactive materials.

Pros:

- Less entry and set-up costs than other PBF techniques

- Less oxidation occurrence due to vacuum environment

- More geometric freedom for creations

- High suitability for metal production and a faster production process than laser sintering.

Cons:

- Less accuracy than laser sintering

- Only exclusively used in metal part production

- A limited build volume than laser printing processes

EBM 3D Printers:

- Arcam EBM Spectra H 3D Printer: Comes with a 6kW HV unit that supports large-scale production. It has a build volume of Ø250 x 430 mm and can exceed a production temperature of 1000 degrees Celsius.

- JAM – 5200: This EBM printer has a maximum beam power of 6kW and a Ø 250 x 400 mm build volume.

Multi Jet Fusion

Invented by HP as their proprietary 3D printer, MJF is a 3D printing process used for the swift production of end-use parts. It works by using an inkjet array to deposit fusing and detailing agents in a bed of powder material and then repeatedly fusing them layer by layer. MJF is used for rigid plastics such as Nylon PA11 and flexible plastics such as Estane 3d TPU M95A.

Pros:

- Speedy printing for a fast production cycle

- Design freedom due to the absence of supports

- Less material waste

- A high-quality surface finish

- Less warping in the final print

- Ability to print fine details

- Low individual print costs

Cons:

- Only single-color models are available

- Expensive initial installation costs

MJF 3D Printers:

- Jet Fusion 4200: Invented by HP, this MJF printer uses polyamide as a printing material and has a max volume of 2210 x 1200 x 1448 mm.

- Jet Fusion 540: Also patented to H, Jet Fusion 540 uses engineering polymers and polyamides and has a max volume of 190 x 332 x 248 mm.

Powder Bed Fusion Advantages and Disadvantages

While PBF undoubtedly contributes to creating significant and novel technology, it also has limitations that could make its optimization difficult.

PBF 3D Printing Benefits

Since the process involves using a laser or electron beam to selectively melt layers of powdered material, this 3D printing process allows for high precision and accuracy in the finished product, making it easier to create high-quality end-use parts or prototypes.

PBF 3D printers can offer a faster manufacturing time than traditional manufacturing processes, work with a wide range of materials, and have a high repeatability level than other traditional manufacturing processes. This is due to a layer-by-layer production process, integration with digital control (through the creation of a CAD file), and high precision, all of which are factors that reduce human error and make it possible to create identical designs continuously.

PBF can also reduce material waste since excess powder can be collected and reused after the production process.

PBF 3D Printing Limitations

One major challenge with using PBF as an AM technique is the higher 3D printing costs associated with the process. PBF 3D printing requires specialized machinery and materials that are expensive to obtain. It’s therefore not the best option for hobbyists or businesses with a smaller production budget.

Another drawback of PBF printing is that it may require additional equipment for post-production processes.

Powder Bed Fusion Applications

PBF technology can be used to make tire molds in automobile companies, applied in surgeries such as hip joint implantations and jaw reconstruction in medicine. One of PBF’s technology applications is evident in JawsTec.

JawsTec is a manufacturing service provider that offers rapid prototyping to innovators, engineers, and entrepreneurs, as well as high-volume production of parts to large businesses. The company specializes in 3D printing, CNC machining, and metal fabrication services, and produces parts for some of the most prominent brands on the planet, including Tesla, Apple, BMW, Ford, Delta, and SpaceX. However, JawsTec faced a challenge with the wastage of end-of-life powder, which not only raised the company’s operating overhead and impacted profit, but also represented a significant environmental issue for a company committed to sustainable manufacturing.

To tackle this problem, JawsTec chose the QLS laser sintering technology by Nexa3D. With the help of Nexa3D’s application engineering team, JawsTec quickly deployed four QLS 230 machines and a QLS 820 machine, completing setup and training in less than a month. The QLS series printers helped JawsTec eliminate sintering powder waste altogether while significantly lowering the waste ratio of sintering powders used, which in turn enhanced company sustainability and streamlined costs.

The QLS series printers also helped JawsTec optimize the usage rates of recycled powder. With the enhanced packing density rate of the QLS series printers, JawsTec was able to utilize 100% of their powders, which was not possible with their older systems that were running a 50% new powder refresh rate. As a result, JawsTec was able to reduce the wastage of end-of-life powder and raise SLS manufacturing output by 50%, due to the platform’s shorter printing cycles. The QLS series printers also provided remote maintenance, which slashed JawsTec’s downtime in the event of build fails–from days to just hours.

“The QLS 230 printers give us the ability to use end-of-life powder from other SLS and MJF machines to produce high-quality parts while eliminating powder waste. On top of the operational sustainability, the smaller build volume of the QLS 230 allows for a much shorter build cycle and cooling cycle with zero negative effect on part accuracy or surface quality.”

–Oscar Klassen, Co-founder & CEO, JawsTec

Use the Best Powder Bed Fusion 3D Printers

With better accuracy, precision, a faster turnaround time, and production processes that cut costs massively, it’s not difficult to see why companies are using PBF 3D printing.

While there’s an array of PBF 3D printers to choose from, we’re confident that the ultrafast QLS 3D printer series from Nexa3D can change the future of your manufacturing business. Go from days and weeks of development and prototyping to hours and minutes–without sacrificing quality and while reducing the cost of ownership.

Interested in learning more about powder bed fusion 3D printing?

Download our Ultimate Production Readiness Guide to determine which plastic powder bed fusion technology is best for your business.