- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

3D printing applications are available in a wide range of industries spanning from medical and healthcare to manufacturing and engineering. 3D technology has made it more possible to produce complex objects that were previously challenging – or impossible – to make using traditional methods.

Plus, with the continued advancements in 3D printing technology, the cost of 3D printing services has become more affordable. This has allowed more small and medium-sized businesses to take advantage of this additive manufacturing technique.

This guide will discuss the various applications of 3D printing and how this technology can enhance productivity and reduce costs.

3D printing applications in medicine and healthcare

Medical professionals can now use 3D printing for various applications, such as creating surgical tools, implants, prosthetics, and organ fabrications. Some of the most notable applications of 3D printing in the healthcare industry include:

Production of dental models

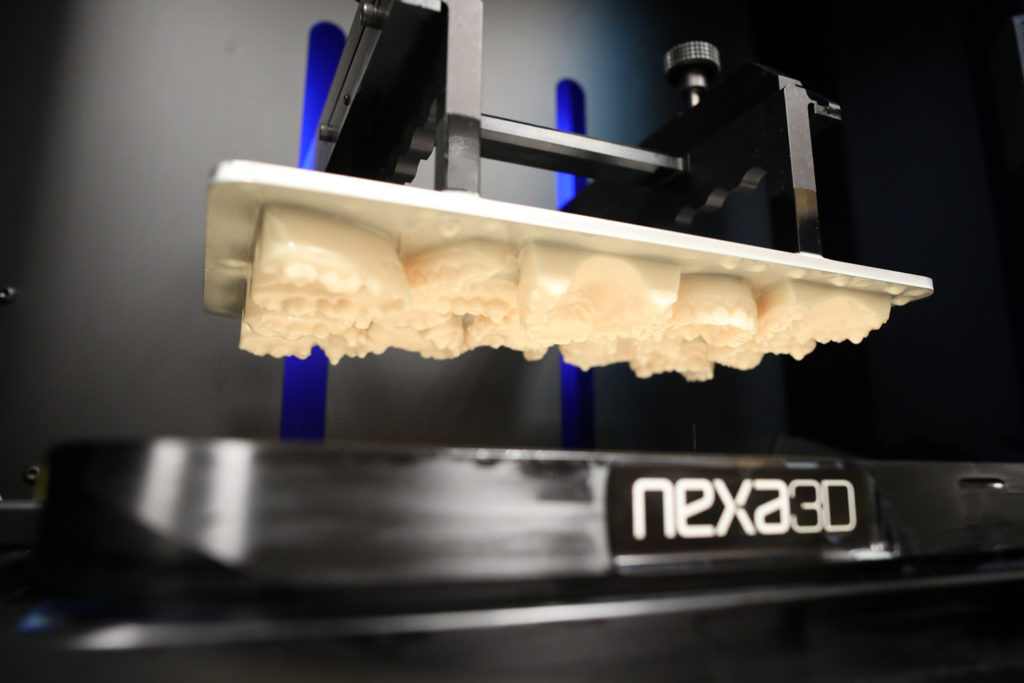

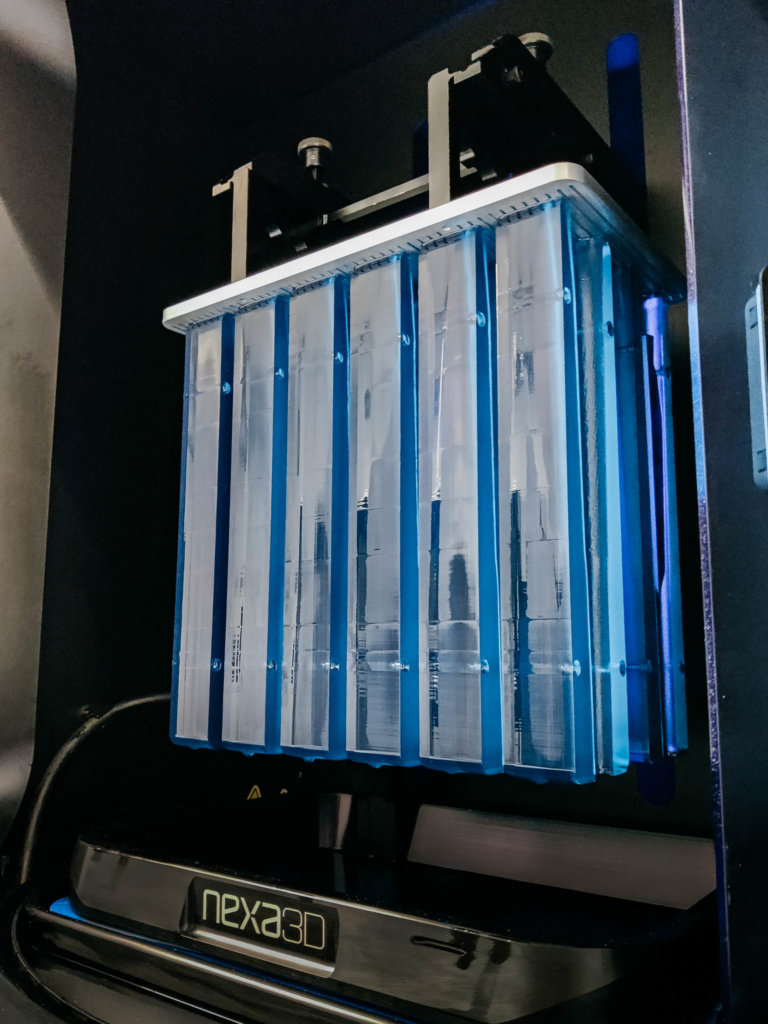

KeyDental x Nexa3D

3D printing is widely used to create dental models and materials, such as crowns and bridges. These 3D-printed models are ready for use in just a few minutes, eliminating the need to outsource the process.

Key Dental Technologies is a digital laboratory that supplies clear orthodontic aligners to MyOrthodontist, the largest network of family orthodontic clinics in North Carolina with 13 physical locations and a mobile clear aligner van.

To expand its average model printing, KDT turned to 3D printing technology. The company adopted Nexa3D NXD 200 dental 3D printer and xModel 2505 resin for the perfect combination of speed, accuracy, and throughput. KDT now meets its target of producing over 2100 orthodontic models per month (with an average of 20 models every thirty minutes) while achieving extreme accuracy and fine feature detailing.

Designing devices and materials for telemedicine

WeMed SKOP

WeMed is one of the companies leveraging 3D printing technology to improve access to healthcare through telemedicine. Intending to provide remote diagnostic medical devices, WeMed partnered with Nexa3D to produce the SKOP™ 3D printed stethoscope, a product that substitutes the need to visit a doctor’s office and allows easier access to remote medical diagnosis.

The collaboration contributes to a global impact by increasing the accessibility of medical devices and improving the efficiency of remote diagnosis. The company’s investment in NXE 400Pro printer has been substantial in bringing the SKOP to a global market in need of these solutions.

Production of orthodontic appliances

Excel Orthodontic x Nexa3D

Excel Orthodontic Lab, a full-scale laboratory, produces orthodontic appliances for patients in the United States. The company has significantly cut production costs and tripled its overall efficiency by using 3D printing technology to produce custom-made retainers, aligners, and dental splints.

After obtaining the NXD 200Pro at one-third of the cost of what it was paying for a three-year lease with other Carbon 3D printers, the firm sees a significantly higher return on investment and a longer lifetime to build value-added products. Plus, Nexa3D’s 3D-printed parts are more precise and make it easier to customize the appliance for better fit, comfort, and efficiency.

3D printing applications in manufacturing

Manufacturers are adopting 3D printers to produce complex objects with intricate geometries, tooling and fixtures, prototype parts, and even end-use products – in a fraction of the time it would take them to produce the same items using traditional methods.

Here are some of the most prominent 3D printing applications in manufacturing:

Production of molds, jigs, and fixtures

3D printing technology is ideal for producing complex molds, jigs, and fixtures. Manufacturers can use 3D printers to quickly produce geometries with intricate designs at a fraction of the cost it would take using traditional methods.

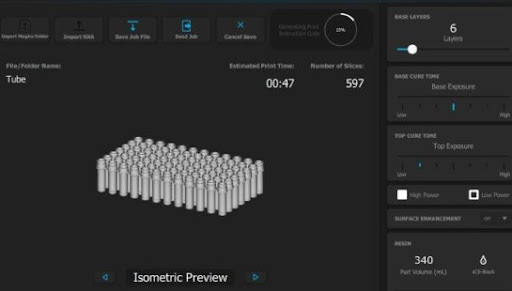

Applied Rapid Technologies (ART) is a good example of a company that uses 3D technology for mold and fixture production. The firm is an additive manufacturing service provider that uses SLA 3D printers and urethane casting to produce customer parts. However, with a minimum of 24 hours per mold, significant amounts of labor, and achieving low-quality results, the firm decided to transition its operations to modern 3D printing.

At the crux of the investment in the NXE 400Pro 3D printers, ART now prints over 25 pieces of mold parts, jigs, and fixtures in an hour or two and uses its advanced post-processing solutions to ensure consistent mechanical properties and predictable part performance. The firm now delivers mold and jig parts on-demand and with superior quality in a fraction of the time it was taking them previously.

Short-run manufacturing and custom production applications

3D printing has proven to be a great tool for short-run production and custom parts. They’re ideal for producing low-volume parts, prototypes, and even end-use products in a matter of hours.

Optimiz3D specializes in 5-axis CNC manufacturing as well as offers 3D printing services. The firm’s portfolio includes on-demand production of prototypes, short-run manufacturing, and custom production applications.

After initially using traditional manufacturing processes, Optimiz3D now leverages 3D printing technology for most of its low-volume and complex parts production. With the acquisition of the NXE 400 printer, Optimiz3D has been able to speed up production times while decreasing overall costs, resulting in decreased lead times and improved customer satisfaction.

Applications of 3D printing in construction

Builders and contractors are increasingly turning to 3D printing technology for its cost-effectiveness and speed of production.

Production of new buildings and architectural designs

WinSun, a Shanghai-based firm, has been leveraging 3D printing technology to revolutionize the construction industry. WinSun specializes in 3D printing architecture and D&R, the production of building new materials, buildings, and walls using a combination of recycled materials and proprietary 3D printing technology.

The firm upgraded its operations in 2015 by building ten 3D-printed houses in under 24 hours. To achieve this feat, the firm used a 20-meter-tall 3D printer to print the components of each house layer by layer before assembling them into completed structures onsite. This process significantly reduced construction costs and production times from months to days.

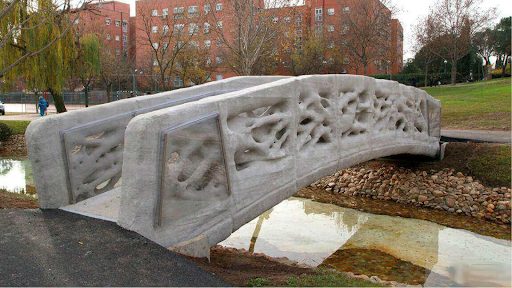

3D pedestrian bridge

3D printing technology for construction of bridges is also on the rise. The Acciona pedestrian 3D bridge in Spain is an example of how 3D printing technology can quickly construct structures. This bridge was printed onsite with a large-scale 3D printer.

3D printing rapid prototyping

With 3D printers, designers and engineers can now easily produce prototypes quickly and accurately. This process reduces the lead times associated with traditional methods while preserving the quality of the parts produced.

The accuracy of 3D printing ensures that only a few iterations are required to perfect a design. But, the speed and efficiency of the production process allows for as many iterations as a product requires.

Rapid prototyping of consumer electronics parts

Firms are using 3D printing technology to produce auto parts. MotoCilino is one example of a company that leverages 3D printing technology to produce lightweight parts.

MotoCilino uses the Nexa3D XiP Desktop 3D printer to increase its design iteration and validation process for producing hardware products. The firm now prints with reduced force and achieves next-generation geometries with ultrafast print times and flexibility.

Aircraft components and parts

3D printing offers more precise and lightweight solutions for aerospace projects. This innovative technology can create everything from turbines and engine plates to structural frameworks and environmental control systems.

Aircraft engineers can now quickly develop custom components tailored to their exact specifications, leading to a new level of efficiency in manufacturing.

3D printing in education

3D printing technology is also being used extensively in the education sector. 3D printing allows students to quickly and easily produce physical models of their designs, allowing them to better understand the concepts they are learning.

3D printers are also a great teaching aid for STEM courses, as they allow students to create intricate models that would be difficult to create using traditional methods. From printed organs for medical science classes to metal parts used for robotics clubs and aerospace engineering projects, researchers in schools can produce test models in mere hours.

Furthermore, 3D printers are incredibly cost-effective and allow institutions to produce teaching materials in-house without ordering them from external suppliers. 3D printing technology also enables schools and universities to customize their teaching materials, allowing them to tailor the lessons they provide based on the needs of their students.

3D printing for transportation

3D printed components allow transportation companies to quickly produce intricate components that are lightweight, durable, and cost-effective.

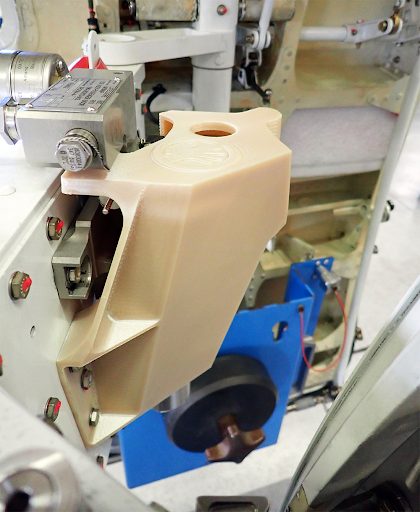

High-speed train component parts

Alstom is one of the largest railway companies that manufactures high-speed trains. The company leverages 3D printing technology to produce components for its trains, including interior fittings and exterior decorative pieces. In Mid-2022, the company also decided to use 3D printing as an alternative to producing new tools and molding.

With the NXE 400Pro Industrial 3D Printer and xABS3843 Resin, Alstom achieved significant cost savings by using 3D printing for its production needs. The 3D printed components also reduce lead times and improve product quality, resulting in a much faster turnaround time from concept design to production.

Automotive parts

William Racing, a Formula 1 racing team, has significantly improved its functionalities by using 3D printing technology to manufacture custom polymer parts for motorsport applications. The racing team partners with Nexa3D and leverages Nexa3D’s high-speed NXE400 3D printer to produce functional wind tunnel components.

The partnership now helps test the aerodynamic properties of William’s race cars, ensuring they are competitive enough for the fast-paced world of Formula 1.

Custom aftermarket components

R3D x Nexa3D

Companies like R3D are leveraging 3D printing technology to create custom-designed parts for classic cars and vehicles. R3D is an automotive and aeronautical engineering company that has been a pioneer in using 3D printing for tooling, prototyping, and production.

Facing the challenge of handling toolless production for over 7,000 custom aftermarket components, R3D required a more advanced 3D printing strategy. The company was able to implement an advanced additive manufacturing workflow after adopting NXE 400Pro industrial 3D printers.

With this 3D printing technology, R3D has increased its production speed by achieving an initial run of 7200 components well within a 3-month timeline.

3D printing consumer goods examples

3D printing is also becoming increasingly popular for the rapid production of consumer goods.

Sporting goods

Wilson Sporting x Nexa3D

Wilson Sporting is one of the world’s largest manufacturers of sporting goods. The company leverages 3D printing technology to produce parts for its golf clubs and other sports equipment quickly and cost-effectively.

Wilson’s design team embraced Nexa3D’s 3D printers and LSPc® technology for better prototype injection mold tooling and multiple-part production. Wilson Sporting was able to reduce costs and time-to-market while still achieving the perfect balance between strength and flexibility.

Wooden products

Woodworkers also use 3D printing in their development processes. It can be used to manufacture knobs, clamping brackets, corner brackets, angle gauge, and other tools that support traditional woodworking processes.

There are also companies that are actually 3D printing wood parts in design configurations that are almost impossible to achieve with conventional subtractive woodworking procedures. For example, the brand Forust uses sawdust and adhesive in a 3D printing process to achieve better design configurations and surface finishes. 3D printing can support more sustainable woodworking practices as well as open new possibilities for wood products.

High-quality toy trucks

KADEN x NXE 400Pro

KADEN is a toy manufacturing company that specializes in producing high-quality toy trucks. However, KADEN hoped to scale up its production without moving from its Norway location–or outsourcing its manufacturing.

KADEN turned to 3D printing as a solution and adopted the NXE 400Pro industrial 3D printer as part of its additive manufacturing workflow. Thanks to this state-of-the-art technology, KADEN is now decreasing design and production costs while increasing output and quality.

Food packaging and bottle development

PepsiCo x Nexa3D

PepsiCo is a perfect example of a 3D application for consumer goods. The company uses 3D printing technology to produce intricate parts and products that are lightweight yet durable, such as food packaging and vending machine components.

By leveraging 3D printing technology, PepsiCo was able to decrease its production costs while increasing build quality and accuracy. They also incorporate the NXE 400 and xPEEK147 material as enablers in bottle development, including accelerating performance simulation and high-quality prototype productions.

Discover New 3D Printing Applications

3D printing has a wide range of applications, and this list is only growing. This exciting technology is allowing for new methods of production that can be faster, more complex, and more affordable than traditional manufacturing.

There are a lot of good 3D printers and 3D printer companies out there. Nexa3D is here to provide the best 3D printing technology with our array of advanced 3D printers that deliver unmatched speed, increase production throughput, and lower total cost of ownership.

Experience the possibilities of 3D printing right now.