- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Selective Laser Sintering (SLS) 3D printers are used in manufacturing and engineering for structure prototyping, small-batch manufacturing, and custom designs. SLS 3D printers can make it easier, faster, and more cost-effective for industries to implement rapid prototyping into their operations.

Of course, this requires using the best SLS 3D printer. SLS 3D printers can vary in the materials they use, build platform size, printer speed, and much more.

This article will explore how SLS 3D printing works, some of the best SLS 3D printers, and what to consider before making a purchasing decision.

What is Selective Laser Sintering 3D Printing?

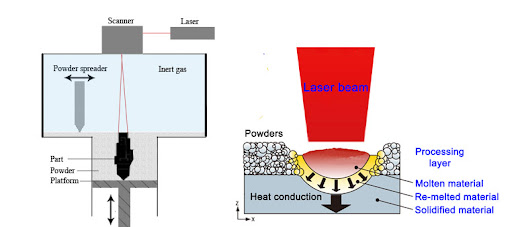

Selective Laser Sintering 3D printing is an additive manufacturing technology that uses a process known as sintering to fuse small particles of various materials like plastic powders and build up an object layer by layer until a 3D structure is formed. The process belongs to the powder bed fusion (PBF) family and involves using a high-power laser as a heat source to bind small, finely powdered polymer material particles to create a 3D-printed object seamlessly.

SLS printing offers high precision and flexibility for producing complex geometries and intricate designs out of materials such as metal, ceramic, and glass powders.

The technology is used to produce parts with varying physical and chemical properties in diverse sectors, such as aerospace, automotive, and healthcare.

How Does SLS 3D Printing Work?

The SLS 3D printing procedure commences with developing a computer-aided design (CAD) model representing the intended structure. These CAD models are generated in 3D modeling software, representing the object to be produced. Once the CAD is created, it is sliced into a format that a 3D printer can understand and execute.

A thin layer of polymer powder is evenly distributed on the build platform inside the printer’s build chamber. The printer preheats the powder to a temperature slightly below its melting point. This allows the laser to consume less energy as it moves across the powder, raising its temperature and solidifying it into the desired shape.

The laser scans each cross-section of the CAD model, selectively heating the powder and fusing the particles to form a single layer of the model. After completing a layer, the printer lowers itself by one layer and repeats the process until all the layers are completed.

After the model has cooled down, it can undergo post-processing techniques like cleaning, sanding, and painting to enhance its surface finish, strength, or rigidity.

SLS 3D printing vs SLM 3D printing

Selective laser melting (SLM) uses a high-power-density laser to fully melt and fuse metallic powders to produce a three-dimensional structure. Like SLS printing, the laser is the heat source that melts the powder particles into one whole structure. However, unlike SLS printing where the laser selectively sinters and fuses particles, the laser in SLM systems completely melts entire layers of a part into one homogeneous solid part.

SLM uses metal powders such as titanium, aluminum, or stainless steel alloys to create metal parts. As a result, structures created using SLM printing techniques have higher density and superior mechanical properties.

Compared to SLS printing, SLM printing usually requires extensive post-processing, needs increased material usage due to the need for support during the printing process, and is more expensive.

SLS vs SLA

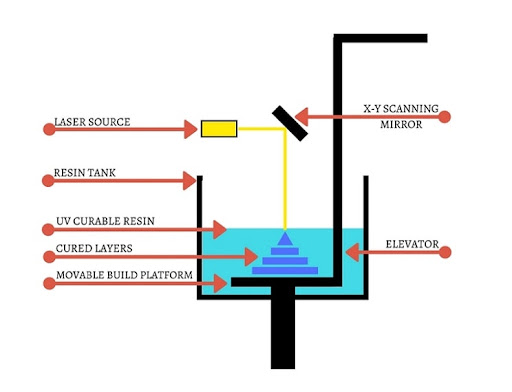

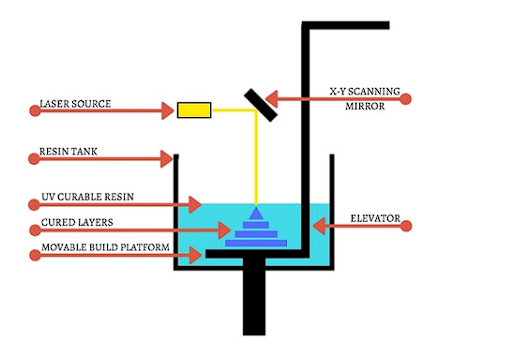

Stereolithography (SLA) 3D printing is a form of vat photopolymerization: a resin 3D printing technique that makes objects by selectively curing photopolymer liquid resin through light-activated polymerization. With SLA, the build platform is lowered into or raised out of a vat of liquid photopolymer resin during the process.

SLA resins come in various formulations, offering a wide range of properties such as flexibility, transparency, or high heat resistance. This helps SLA technology excel in producing highly detailed, accurate, parts with intricate geometries and a smooth surface finish.

Comparatively, SLS technology is compatible with a broader range of 3D printing materials, including nylon, thermoplastic elastomers, polystyrene, and even metals like aluminum and titanium. The powdered nature of the materials allows for more design flexibility and the production of functional parts with robust mechanical properties.

Best Industrial SLS 3D Printers

With the numerous SLS printers available in the market today, it can be difficult to know which is the best option for your manufacturing and industrial-grade engineering needs.

To help, we created this list of the best industrial SLS 3D printers for manufacturing and engineering operations.

1. QLS 260

QLS 260 is an open platform selective laser sintering 3D printer that offers limitless application options thanks to its compatibility with 16+ qualified materials including a range of Polyamides, PP, PBT, and TPU. Other than these approved materials, the QLS 260 printer is also compatible with patented metal powders from headmade materials®.

QLS 260 offers an unrivaled 21-hour cycle speed using a single 60 Watt CO2 laser and an estimated 22mm per hour build speed. With a 230 x 230 x 250mm build volume, it is perfect for rapid prototyping and the creation of end-use products using a broad range of high-temp thermoplastic materials.

QLS 260 is not only one of the fastest 3D printers but also has one of the lowest entry points in the professional selective laser sintering market, combined with lower operating costs due to its powder refresh rate of just 20% and use of third-party materials to reduce 3D printing costs. It is also compatible with cold metal fusion and can produce titanium and steel parts.

Printer specifications:

- One of the lowest costs of entry in the SLS printer market

- Cold metal fusion compatible

- 230 x 230 x 250mm build volume

- Open material platform and material versatility (including a range of Polyamides, PP, PBT, TPU, as well as the patented metal powders from head made materials)

- Powered by the intuitive NexaX 3D printer software suite

Best For: The QLS 260 printer is a workhorse best for harnessing material flexibility and versatility to create durable structures with robust mechanical and thermal properties. Also perfect for those who prioritize environmental sustainability, and are looking for a printer that can create titanium and steel parts.

2. QLS 820

QLS 820 is a quad laser system offering unprecedented production capabilities designed with automation and scalability. The QLS 820 produces up to 4x the throughput of traditional laser sintering 3D printers and other polymer powder bed technologies. The QLS 820 has smart automation, removing pain points in capacity utilization and downstream labor intensity. It can print up to 8 liters per hour at 20% job density.

QLS 820 has an open-source platform that allows for the printing of many materials, including PA12, PA11, and Polypropylene, as well as aluminum, glass, and fiber-filled options.

As one of the best 3D printers in the market today, Nexa3D QLS820 is trusted by many reputable manufacturers for their production needs. The drone manufacturing company, SmartDrone, used the QLS820 to scale up its production throughput. SmartDrone gained a 60% faster build speed, 2x the packing density, larger build volume, hot-swappable build units, and more.

Printer specifications:

- Open source platform for plastic, metal, and fiber-filled materials

- High throughput (4x the throughput of traditional SLS printers)

- Smart automation & advanced fleet management software

- 350 x 350 x 400 mm build volume

Best For: High-volume production manufacturing in a variety of materials. Injection mold tolerances for full production capabilities, including high temp thermoplastics like PBT and PA6 materials.

3. QLS 230

The QLS 230 printer is one of the most affordable fast-cycle industrial SLS printers in the market today. It offers a swift 24-hour cycle speed using a single 30 Watt CO2 laser to manipulate a broad range of high-temp thermoplastic material into high-quality 3D structures.

The QLS 230’s versatility is notably one of its most important properties, making it one of the best industrial 3D printers today. It is compatible with 10+ qualified nylon and metal fusion materials and also works with recycled powders from HP and EOS for ultimate operational sustainability.

In addition to this, the printer’s compatibility with cold metal fusion makes it perfect for a wide range of metallurgical manufacturing processes in the engineering industry, including the creation of titanium and steel parts.

Printer specifications:

- Lowest cost of entry and low operating costs

- 20% powder refresh rate

- 230 x 230 x 230mm build volume

- Compatible with 10+ qualified nylon and metal fusion materials

- Up to 20mm per hour build speed

- Utilizes recycled powder from HP and EOS

Best For: Companies who look for versatility, swift printing, high-quality structures, and sustainability. They are especially great for creating durable and tough titanium and steel parts.

Learn more about QLS 230 here.

4. 3D Systems SLS 380

The 3D Systems SLS 380 is a production-grade system that offers high throughput, versatility, and repeatability for manufacturers looking to integrate SLS additive printing in their factory-floor ecosystem. This large 3D printer features a closed-loop process for consistency, a water-cooled laser for thermal uniformity, automated material handling, and a fully automated post-processing workflow.

The SLS 380 printer uses a complementary 3D Sprint software for all editing, printing, and management practices. It is compatible with production-grade nylon materials.

Printer specifications:

- 2.7 l/hr production speed

- Build envelope capacity 15 x 13 x 18 in (381 x 330 x 460 mm)

- Automated material handling using material quality center (MQC)

Best For: Industrial-scale, process controlled additive manufacturing.

5. HP MJF

HP Multi Jet Fusion is HP’s patented SLS printer. This series of printers that work by combining inkjet-style printing with powder fusion techniques to create high-quality and functional parts. These industrial SLS printers offer high volume, material flexibility, and scalability to create final printed parts.

Of the many printers in the HP MJF series, the HP Jet Fusion Series 5600 is an industrial printer designed for flexible production at scale. It has a large build volume of 380 x 284 x 380 mm and a building speed of up to 3,466cm3 per hour. The 5600 series of 3D printers is compatible with Ethernet, the HP software suite, and Autodesk third-party software.

Printer specifications:

- 380 x 284 x 380 mm build volume

- 3,466cm3 per hour

- 0.09 mm layer thickness and 1200 dpi print resolution

- Supports file formats 3MF, STL, OBJ, and VRML

- Material flexibility and reusability

Best For: Building swift and cost-effective intricate 3D designs with high accuracy.

6. EOS Formiga P 110 Velocis

The Formica P 110 Velocis is used to build small to medium-size structures. It is compatible with a wide range of polymer materials, including Polyamides (PA), Thermoplastic Elastomers (TPE) and Polyaryletherketones (PAEK). It has a low running costs that keeps maintenance fees to a minimum and a fast print speed.

The Formica P 110 Velocis is a great option for rapid prototyping and the creation of durable end-use products. However, its inability to properly recycle used powder makes it a poor choice for sustainability.

Printer specifications:

- 200 x 250 x 330 mm build volume

- Build rate of 1.2 l/h with a packing density of 5%

- Approximately 600 kg (1.323 lb)

Best For: Companies that require low processing costs and small-scale production of high-resolution and intricately detailed parts.

7. 3D Systems ProX SLS 6100

The 3D systems ProX SLS 6100 is a large-scale, industry-grade SLS printer suitable for production of tough parts from a wide-range of production or engineering-grade nylon materials. It offers a fast build time, 25% larger build volume capacity, and repeatability (consistently creating identical designs). It comes with a Material Quality Control (MQC) system that enables automated mixing, recycling, and manual-free material transportation to the printer.

Printer specifications:

- Wide material compatibility

- 381 × 330 × 460 mm build volume

- Automated production capabilities

Best For: Nylon and thermoplastic 3D printing applications.

8. EP-P3850 – Eplus3D

The EP-P3850 Eplus3d is an SLS printer for industrial-grade production and research processes manufactured by Eplus3D, a Chinese company with two facilities in Beijing and Hangzhou. It is suitable for various polymer materials, including PA12, PA12GF, PA11, PA11CF, and TPU. The printer offers a large build size and is a great option for producing functional end-use products in various engineering industries.

Printer specifications:

- Build volume of 380 x 380 x 500 mm

- Works with a wide range of polyamides

- Detachable forming cylinder

Best For: Producing functional end-use products in various engineering industries.

Best Desktop SLS 3D Printers

Desktop SLS 3D printers allow users to create functional prototypes, complex geometries, and small-scale production parts with high accuracy and durability–right at their desk.

Although there are numerous SLS desktop printers available in the market today, some of the best options include:

1. Fuse 1 Formlabs

![]()

The Fuse 1 3D printer offers many features of a traditional SLS printer but on a smaller scale and with less footprint. Its build chamber is significantly smaller than that of industrial 3D printers using SLS technology.

It is compatible with a few of SLS’s most in-demand industrial-standard powders, making it a good option for low-volume prototyping and some production opportunities.

Printer specifications:

- Touchscreen display and camera view of printing process

- Limited range of materials

- Build volume 165 x 165 x 300 mm (6.5 x 6.5 x 11.8 in)

- Fiber laser

Best For: Best for manufacturing durable small-batch parts

2. Lisa Pro Sinterit

The Lisa Pro Sinterit is an SLS 3D printer with an open environment and access to a wide range of materials. It offers an open printing system that supports various materials including multiple PA11 varieties, PA12, PP Polypropylene, and Flexa varieties. The Lisa Pro Sinterit includes 32 open printing parameters and an option to easily change materials.

Printer specifications:

- Max print volume: PA – 110 x 160 x 230 [mm] (4.3 x 6.3 x 9 [in]) Flexible – 110 x 160 x 245 [mm] (4.3 x 6.3 x 9.6 [in])

- 3 [mm/h] build speed

- Microsoft Windows compatibility

Best For: Prototyping and small-batch production of structures across various industries.

3. Sinterit Lisa X

Sinterit Lisa X is a compact SLS 3D printer with a printing speed of 14 mm/hour and a platform compatible with an array of printing powders, including PA12 industrial, PA11 Onyx, PA11 CF, and Polypropylene. It comes with dedicated 3D printing software, ATEX Safety certification for working with powders, and an expert mode for more control over the bed and recoater.

Printer specifications :

- Compact size that takes up less than 2m2

- IR Fiber Coupled Diode laser

- Inert gas control system

- Max print volume: TPU-based/ Flexible material- 130x180x340 mm (5.1 x 7.1 x 13.3 in), PA/PP- 130x180x330 mm (5.1 x 6.7 x 13.3 in)

- Compatible with Microsoft Windows 10 or higher

- Supports file types STL, 3MF, OBJ, 3DS, FBS. and DAE.

Best For: Manufacturers who require a printer with an impressive size to print ratio.

4. Formlabs Fuse 1+ 30W

Formlabs Fuse 1+ 30W is a compact SLS 3D printer that offers rapid printing of industrial-grade 3D printing materials. It typically prints a 3D model in 14 hours. The Formlabs Fuse 1+ 30W is built with a complete SLS ecosystem to streamline workflow from setup to finished parts while ensuring complete design freedom.

With the Formlabs Fuse 1+ 30W, manufacturers can print functional models from a wide range of materials, including Nylon 11, Nylon 11 CF, Nylon 12, Nylon 12 GF, and polypropylene powder.

Printer specifications

- 165 x 165 x 300 mm build volume

- 30W Fiber Laser

- Compatible with six materials

- Inert gas and air environment

- 24/7 Uptime with Remote Control Dashboard

Best for: Designers, manufacturers, or 3D printing services looking for a small printer with industrial printing capabilities.

5. Sharebot SnowWhite 2

The Sharebot SnowWhite 2 is an SLS printer equipped with a 14 CO2 laser, a nitrogen/argon modified atmosphere, and fully open parameters that can work with any kind of powder. It offers remote control features, Ethernet connectivity, and an ability to have more than one spoofer distributor to instantly change build volume to match the needs of specific printing projects.

Printer specifications

- 100 x 100 x 100 mm standard build area

- Building speed of 35 mm/h

- XY resolution of 100 microns with Z resolution of 50 microns

- Scan speed of 3500 mm/s

Best for: Scalable 3D printing operations.

More About Selective Laser Sintering 3D Printing

Some more information to know about SLS 3D printing include:

SLS 3D printing applications

SLS is a versatile technology that can be applied to a wide range of functional applications across various industries like aerospace, automobile, consumer products, and even healthcare. It is commonly used in these industries for 3D-printed tooling, rapid prototyping, manufacturing of specialized parts, or custom production and mass manufacturing.

SLS 3D printing materials

The materials used for 3D printing vary from plastic to metal, ceramic, and glass powders. Some common material options include:

- Polyamide: Polyamide, often referred to as “nylon”, is a synthetic polymer created by linking long and thin filaments with an elastic structure. There are different types of PA suitable for 3D printing, including Polyamide 6 (PA6), Polyamide 11 (PA11), and Polyamide 12 (PA12).

- Polypropylene (PP): PP is a crystalline synthetic thermoplastic polymer made from a combination of propylene monomers. It is tough, rigid, and commonly used in SLS 3D printing due to its excellent durability, high plasticity, high elongation, and low moisture absorption.

- Polyethylene (PE): PE is a lightweight synthetic thermoplastic resin made from the polymerization of ethylene. It is a versatile 3D printing material with a high chemical resistance, high stability under low temperatures, and excellent wear resistance.

- Thermoplastic Urethane (TPU): TPU is a recyclable and eco-friendly thermoplastic elastomer with high flexibility, excellent wear resistance, and a typical smooth finish. While its rubber-like features make it a commonly used SLS 3D printing material, TPU is highly prone to warping and may be difficult to work with.

- Thermoplastic Elastomer (TPE): TPE is another runner-like material that can be recycled. It is lightweight, flexible, fatigue-resistant, solvent resistance, and resistant to both low and high temperatures.

- Polyketone: Polyketones are a family of non-toxic high-performance thermoplastic polymers with a high impact strength, excellent chemical resistance, and excellent wear resistance. They are typically used in mechanical and automotive industries as fuel lines and to make products such as housings or switches.

- Polybutylene Terephthalate (PBT): PBT is a highly-crystalline polymer with excellent strain resistance, high strength, good creep resistance, low moisture absorption, and high tensile strength. It is often used in SLS 3D printing to produce durable models with impressive mechanical properties in various industries, including engineering and biomedical fields.

- Polymer-Coated Metal Powders: Polymer-coated metal powders are made by coating metal particles in a thin layer of polymer. Polymers and metals are bonded together to create polymer-coated metal powders in a process known as Cold Metal Fusion patented by Headmade materials. Only a few SLS 3D printers like Nexa3D QLS 3D printers can carry out Cold Metal Fusion to produce durable and strong materials.

Benefits of SLS 3D printing

SLS offers several benefits, including rapid manufacturing of final-use products with high-quality finish, cost-effectiveness in producing a small number of parts over a short period of time, and the ability to create models with superior mechanical properties due to the strong adhesion between each 3D-printed layer.

SLS 3D printing also enables quick reiteration of designs, reduced product development time, and freedom over printing process compared to other technologies such as high speed sintering (HSS).

Additionally, certain SLS 3D printers like Nexa3D QLS 230 and QLS 260 support sustainable manufacturing by allowing the reuse of unused powder material from previous 3D printing processes. This reduces waste and printing costs compared to other traditional production methods.

SLS printing encourages the use of a wide range of materials ranging from polymers to powders, making it easier to explore 3D printing with polymers and powders alike.

SLS 3D printer price

SLS 3D printer costs vary depending on the manufacturer, specifications, capabilities, and other features. Depending on the type of 3D printer, the average cost of a printer can range from $100-$500 for beginner 3D printers to $500-$1500 for hobbyist printers, $1,000-$10,000 for professional desktop printers, and $10,000-$100,000+ for large industrial printers. However, SLS 3D printers are typically more expensive than other types of 3D printers due to their advanced technology and precision. SLS 3D printer price can range from $20,000 to well over $500,000.

It is important to know that although the printer is the bulk of the cost associated with 3D printing, there will be other budgetary considerations to make beyond the SLS 3D printer price. Some other factors to consider when it comes to 3D printing costs include printing technology, material used, size of the printing project, design complexity, software used, required post-processing steps, and labor, including the cost of assembly and printer maintenance.

SLS printing technology typically requires a controlled environment to house the printers, which contributes to expenses. This printing technology also has higher implementation costs due to the need for additional safety measures and specialized equipment. These factors contribute to the higher upfront costs and ongoing operational expenses associated with SLS 3D printers.

SLS 3D printing vs SLA 3D printing

SLA 3D printing is a form of vat photopolymerization: a resin 3D printing technique that makes objects by selectively curing photopolymer liquid resin through light-activated polymerization in resin 3D printers. With SLA, the build platform is lowered into or raised out of a vat of liquid photopolymer resin during the process. SLA is often used interchangeably with masked stereolithography (mSLA 3D printing), which is a variation of SLA technology that uses a digital micromirror device (DMD) to selectively cure resin instead of laser as with standard SLA.

SLA resins come in various formulations, offering a wide range of properties such as flexibility, transparency, or high heat resistance. This helps SLA technology excel in producing highly detailed, accurate, parts with intricate geometries and a smooth surface finish.

Comparatively, SLS technology is compatible with a broader range of 3D printing materials, including nylon, thermoplastic elastomers, polystyrene, and even metals like aluminum and titanium. The powdered nature of the materials allows for more design flexibility and the production of functional parts with robust mechanical properties.

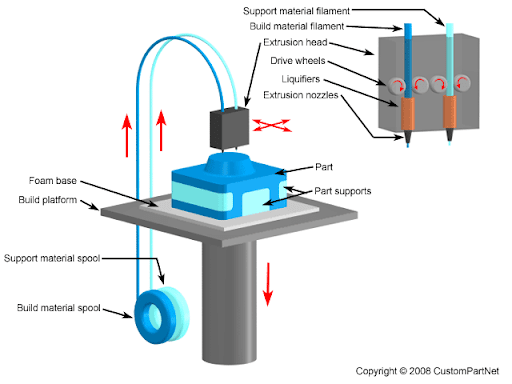

SLS 3D printing vs FDM 3D printing

FDM, also known as fused deposition modeling or fused filament fabrication, uses a heated nozzle to make and deposit melted thermoplastic filament layer by layer until the design is fully created. The plastic or thermoplastic filament is fed through a heated nozzle where it’s melted and then deposited onto the build platform. Once the first layer has cooled, the next layer is deposited. This continues until every layer is complete and the structure is fully formed.

On the other hand, SLS 3D printing uses a high-powered laser to selectively fuse and sinter powdered thermoplastic materials later by later to create 3D objects.

FDM is widely used across various industries such as architecture, consumer goods, medical, aerospace, and even automotive for 3D printing car parts.

Choose the Best SLS 3D Printer

To enjoy the numerous advantages this additive printing process offers, it is essential to invest in the right and choose the best SLS 3D printers.

Although every printer on our list offers swift printing speed and high-quality operations, Nexa3D’s range of SLS 3D printers provide unprecedented capabilities, including smarter operations and the fastest print speed in the market today.

Designed with automation and scalability in mind, Nexa3D printers offer high quality, precision, accuracy, and large build volumes to accommodate numerous printing needs.

Ready to experience it yourself?