- Metal 3D Printing Guide: What It Is & How It Works [2024] - February 5, 2024

- Metal Injection Molding: What It Is & Top Alternatives [2024] - January 11, 2024

- 11 Fastest 3D Printers on the Market (Industrial and Desktop) [2023] - December 11, 2023

From industrial prototyping to functional parts for the medical and dental fields, resin 3D printing has revolutionized various industries. An essential component of this groundbreaking technology is the resin material used to make high-quality, durable products with smooth surface finishes.

This guide will review the basics of resin 3D printing, various types of 3D printer resins, their physical properties, and their uses across a variety of industries.

What is Resin 3D Printing?

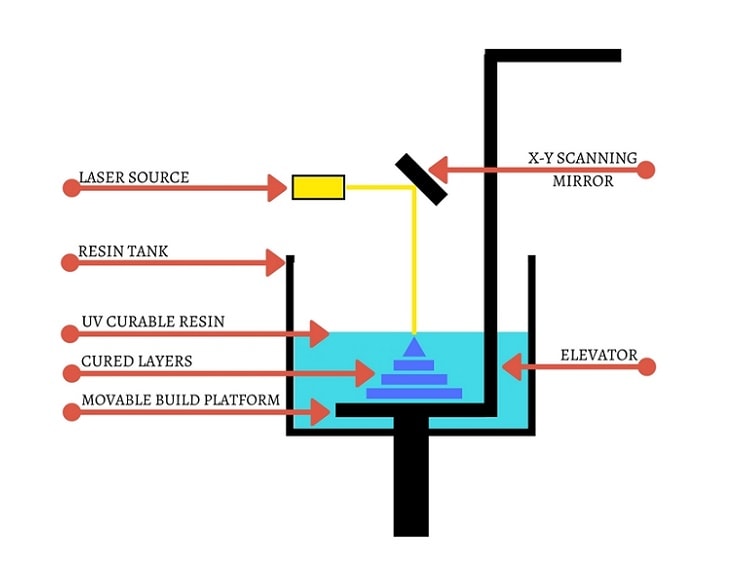

Resin 3D printing, of which vat photopolymerization is most commonly used, is an additive manufacturing technology that utilizes resins to make complex 3D-printed objects. Resin 3D printers start with a build platform filled with liquid resin. The printer selectively emits 405nm short wavelength light, layer by layer, which causes the liquid resin to solidify. This process continues iteratively until all the layers of the object have been successfully printed.

There are a few 3D printer resin technologies to know:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Masked Stereolithography (mSLA)

Stereolithography

SLA technology is the first generation of resin 3D printing. It operates by utilizing ultraviolet lasers to solidify liquid resin, resulting in the creation of solid objects. SLA 3D printers offer excellent accuracy and resolution, making them suitable for applications that require intricate designs and fine details, such as miniatures, figurines, and architectural models as well as very large parts.

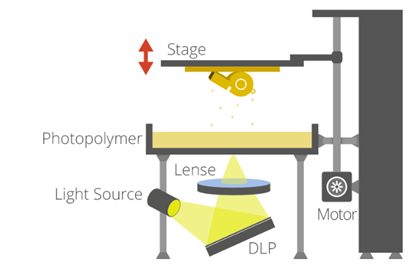

Digital Light Processing

Digital Light Processing represents the second generation of resin 3D printing, using 385 nanometer wavelength ultraviolet light to solidify resin materials. DLP works with a liquid resin in conjunction with a DLP chip and projector to display the images of each layer, subsequently curing them upon exposure to ultraviolet light.

In the DLP process, the projector swiftly projects the entire layer image at once, significantly reducing the overall 3D printing time. This characteristic makes DLP a notably faster printing method when compared to SLA, rendering it highly suitable for a wide array of applications. However, due to the projected light at varying angles, the pixel shape can be altered in different areas, which poses challenges in achieving complex geometries and maintaining precise build quality across the build platform.

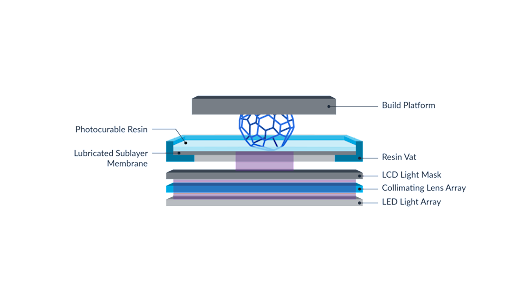

Masked Stereolithography

Masked Stereolithography, or mSLA, is the latest advancement in resin 3D printing technology, representing an evolved version of SLA and DLP. What sets mSLA apart is its utilization of an LED array light source coupled with an LCD screen instead of a laser or a single projection point .

In mSLA, the LED array projects light through an LCD panel, selectively masking specific pixels while allowing only the unmasked pixels to transmit light. Curing solely occurs in the unmasked section, enabling users to achieve highly detailed prints at a faster pace than traditional SLA and DLP printers, all while maintaining exceptional build quality through pixel-level control across the build.

Nexa3D’s resin 3D printers enhance the power of mSLA 3D printing with proprietary Lubricant Sublayer Photo-curing (LSPc®) technology. LSPc® combines a UV LED light array with an LSPc Optical lens layer, ensuring uniform light distribution at ultrafast speeds. Additionally, the patented lubricated Everlast 2 membrane significantly reduces the “peel force” exerted during the detachment of each layer from the vat’s base. This remarkable combination allows for the market’s fastest mSLA printing with the largest build area in its class, all without compromising image quality.

mSLA is compatible with various types of SLA resin 3D printing materials, making it suitable for a diverse range of applications. It offers excellent resolution, accuracy, and process repeatability, accommodating a wide range of compatible resins such as flexible, biocompatible, and castable resins.

Industrial vs. Hobbyist Resin 3D Printers

Resin 3D printing has gained significant popularity in both industrial and hobbyist settings. While the fundamental principles remain the same, there are distinct differences between industrial and hobbyist resin 3D printers.

- Scale and Capacity: Industrial resin 3D printers are designed for high-volume production and can handle demanding manufacturing requirements with exacting specifications. In contrast, hobbyist resin printers have a more limited build volume, making them suitable for smaller-scale projects and personal use.

- Print Quality and Precision: Industrial resin printers are capable of producing intricate and detailed parts with tight tolerances. Hobbyist resin printers can offer good print quality–but often can’t achieve the same level of precision as industrial-grade machines.

- Speed and Productivity: Industrial resin printers employ faster printing processes, larger resin tanks, and automated systems to enable rapid and continuous production. Hobbyist resin printers generally have slower print speeds and are better suited for smaller, individual projects that prioritize print quality.

- Material Compatibility: Industrial resin printers often support a broader range of materials, including specialized resins with high temperature resistance, flexibility, or biocompatibility. They offer versatility in material selection to meet specific application requirements. Hobbyist resin printers usually have a more limited selection of compatible resins, with a focus on general-purpose materials with various aesthetic differences like color.

An example of an industrial resin 3D printer is the Nexa3D XiP Pro. This resin 3D printer is designed to meet the needs of industrial and dental applications with a spacious 19.5L build volume and ultrafast printing speeds. This cutting-edge 3D printer incorporates the innovative LSPc® technology, which enables the XiP Pro to achieve exceptional levels of accuracy, tight tolerances, and an impeccable surface finish.

3D Printer Resin Properties

The various characteristics of resin materials determine the strength, durability, and functionality of the final product.

Tensile Modulus

Tensile modulus is defined as the stress-strain ratio within the elastic limit. It is an important mechanical property of 3D printer resin that determines its ability to withstand tensile forces. A high tensile modulus communicates a high degree of stiffness while a low tensile modulus indicates a material might be more susceptible to elastic deformation.

Tensile Strength

Tensile strength is the maximum stress that a material can withstand before breaking under tension, which impacts the durability of the finished product. A high tensile strength is necessary for parts that need to be subject to constant external forces, such as mechanical or structural components.

Tensile Elongation at Break

Tensile elongation at break is the maximum deformation that a material can withstand before breaking under tension. A high tensile elongation ensures a product can resist and maintain its original shape after deformation. It’s a helpful property for resins used in products that encounter stretching forces, such as plastic and rubber components.

Flex Modulus

Flexural modulus is the ratio of the stress to the strain during bending or flexural deformation. It’s an essential property for products that experience any bending forces, such as springs or support beams.

Flex Strength

Flexural strength is the stress at which a material will break under bending or flexural deformation.

Notched Izod

Notched Izod impact strength measures the amount of energy required to break a material under high-velocity impact. It’s important for products that encounter high-velocity impacts or are exposed to harsh environments.

Water Absorption

Water absorption indicates a resin’s tendency to absorb moisture over time. This property is important to consider for applications where exposure to water or humidity is likely since this can affect the material’s other mechanical properties.

Hardness Shore D

Shore D hardness measures the resistance of a material to indentation. High Shore D hardness is essential in products that need to maintain shape under constant pressure.

Color

While not a mechanical property, the color of the resin is an essential consideration for aesthetic and functional purposes.

Types of Industrial 3D Printer Resins

This section explores three major categories of industrial 3D printer resins: General Purpose Resins, Engineering Resins, and Dental Resins.

General Purpose Resins

General purpose resins are widely employed in the field of prototyping due to their exceptional qualities. These resins excel at producing highly detailed prints with a smooth surface finish and excellent color or clarity. They often boast faster printing speeds, making them perfect for iterative design and testing processes.

Resin Types:

- x45: A versatile and durable material suitable for prototyping. It offers excellent optical clarity, high resolution, and good mechanical properties like strength and reliability, making it an ideal choice for a wide range of applications.

- xMODEL15: An economical modeling material with superb speed and surface finish quality. Suitable for polishing, painting, and plating, providing next-level finishes. Derived from plant-based materials, it has a low odor and can be easily cleaned with water and gentle brushing.

- xMODEL17-Clear: A rigid and durable modeling material known for its enhanced clarity. It is ideal for precise prototyping applications that demand fine feature details and high-quality translucent or transparent surface finishes.

- xMODEL35: A rigid, high-performance modeling resin with excellent mechanical properties. It maintains dimensional accuracy in extreme temperatures and humidity. Suitable for functional models and end-use applications, xMODEL35 ensures first-time print success and achieves fine detail and precision with Nexa3D’s LSPc® technology.

- xPRO410: This rigid resin material offers extreme accuracy and exceptional surface finish. Designed for use with Nexa3D’s NXE, XiP, and XiP Pro 3D printers, it is a great solution for general-purpose prototyping.

Example Use Cases:

Kaden

Kaden, a toy manufacturer based in the Czech Republic, has integrated the advanced capabilities of the NXE 400 Pro system into their operations. By harnessing the power of xPRO410 resin, Kaden successfully prototypes and mass produces parts for their range of die-cast toy trucks. This strategic implementation of resin 3D printing enables Kaden to optimize both their new product development and manufacturing processes, resulting in streamlined operations and enhanced efficiency.

Read More About General Use Resins

Engineering Resins

In recent years, engineering resins have undergone significant advancements. The market now offers a range of specialty resins from high-temperature molding tools to versatile ABS-like production materials, as well as electrostatic dissipative (ESD) resins and remarkably flexible rubber-like elastomers. These specialized resins are pushing the boundaries of what is achievable with resin 3D printing, enabling true manufacturing-grade outputs.

Resin Types:

- xABS3843: This tough and durable material has excellent flexural and tensile properties, high green strength, and good heat deflection temperature. Tested under QUV exterior weathering conditions, it shows minimal change in tensile and impact properties after 800 hours.

- xCE: Offers high stiffness and temperature resistance, emulating the aesthetics and long-term durability of injection molded nylons, polyesters, and polyimides. It demonstrates its resilience in challenging outdoor conditions involving sun, humidity, and heat.

- xPEEK147: This stiff and heat-resistant material maintains exceptional long-term stability even at temperatures surpassing 100°C. It is an ideal choice for prototypes, end-use parts, and rapid tooling for plastic molding needing to operate in elevated temperatures.

- xCERAMIC3280: Enables the production of rigid parts with exceptional heat deflection temperature and high tensile modulus at remarkable speeds. Used for tooling applications, wind tunnel testing models, and products that demand a ceramic appearance and tactile experience or products that need to operate at elevated temperatures (i.e. injection molding).

- xESD: Ideal for the electronics manufacturing industry, xESD enables the rapid production of custom jigs, fixtures, grippers, assembly aids, and enclosures, safeguarding high-value electronic components from electrostatic damage.

Example Use Cases:

Alstom

Alstom is a French-based rolling stock manufacturer that manufactures train cars for some of the world’s largest rail agencies. The high-speed trains they manufacture can be found in every major rail market across 6 continents and over 60 countries around the world.

In mid-2022, the team was tasked with producing hundreds of footrests that required replacements. Using xABS3843 resin with their NXE 400 Pro 3D printer, they were able to manufacture hundreds of passenger footrests to replace designs that were no longer available from suppliers.

Read More About Engineering Resins

Dental Resins

The growing demand for customized dental pieces has paved the way for a diverse array of highly productive dental resins. These advanced resins are designed to cater to the specific needs of the dental field, enabling the production of a wide range of dental components. From detailed dental models to protective guards, from surgical guides to orthodontic aligners, dental resins offer exceptional precision and reliability.

Resin Types:

- xDENT341-Beige: High-resolution material for 3D-printing precise removable die models. Used to achieve accurate margins and contacts for custom prosthodontic treatments, ensuring a proper fit. Ideal for crowns, bridges, and implants.

- xDENT241-Gray: High-resolution dental model material for ultrafast production of thermoformed models, removable dies, and other dental applications. Used to achieve exceptional detail and accuracy in dental models.

- xMODEL2505: Dental model material for production of orthodontic models and other dental applications.

- KeyModel Ultra™: A material designed for 3D printing of dental and orthodontic models.

- KeySplint Hard®: A splint material with comparable performance to lab-processed Lucitone 199. Offers excellent wear resistance, no tearing or cracking, and exceptional fatigue failure resistance.

- KeySplint Soft®: KeySplint Soft is a strong material for splints, night guards, and bleaching trays.

- KeyGuide®: KeyGuide is a stiff, biocompatible (class I) 3D Printing resin designed to create surgical guides. The material is stiff and durable to withstand the forces of guided surgery in the oral cavity.

Example Use Cases:

KeyDental Technologies

Key Dental Technologies is a digital laboratory supplying orthodontic clear aligners to MyOrthodontist, the largest network of family orthodontic practices in North Carolina.

Key Dental Technologies uses the xModel 2505 resin from BASF for its dental model material and leverages Nexa3D’s LSPc® photopolymer printing technology, allowing them to keep up with growing demand and produce 2100 models per month on just one 3D printer.

“I will always choose [Nexa3D] because of the high definition, plus it’s faster, has a greater capacity, and it’s cost effective.”

Cristina Montiel, Laboratory Technician at Key Dental

More About 3D Printer Resins

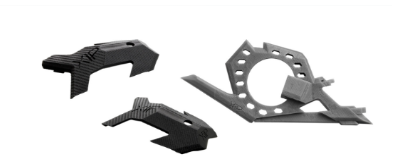

3D-printed product created by Nexa3D’s XiP Pro resin 3D printer.

Is 3D Printer Resin Expensive?

Compared to filament-based 3D printing materials like PLA or ABS, resin can be more expensive. However, resin-based printing materials provide more value to professional users. This is because Vat polymerization delivers better part quality, smoother finishes, and finer detail.

Strongest Resin for 3D Printing

It’s crucial to recognize that strong is a very relative term when it comes to 3D printing materials. The strength of a resin is not solely dependent on a single characteristic: it varies by impact resistance, tensile strength, and tensile modulus.

Different types of resins offer varying levels of durability and mechanical properties. Engineering resins, such as tough or impact-resistant resins, tend to be stronger than standard resins. One example of this is carbon fiber resin, which is a highly durable and versatile material used for creating components in the automotive and aerospace industries.

Is Resin Stronger Than PLA?

As we just mentioned, the strength of 3D printed materials is determined by various factors including impact resistance, tensile strength, tensile modulus, and tensile elongation. Therefore, not all resins will be stronger than PLA or vice versa.

For example, xPEEK147 boasts an impressive tensile strength of up to 75MPa. But for exceptional tensile modulus, the xCERAMIC3280 leads the way at 9410MPa and xFLEX402 offers a remarkable tensile elongation at a break of 230%.

Where to Buy Resin for 3D Printer

Resin can be bought at most locations where you can get 3D printing materials and equipment. When purchasing resin, it is crucial to ensure compatibility with your specific 3D printer model. Therefore, opting for a printer that supports a diverse range of materials is advisable to expand your options. Fortunately, Nexa3D printers boast an open platform design, granting you virtually limitless possibilities when it comes to material selection.

Nexa3D printers offer a broad range of high-performance manufacturing materials, ranging from strong and durable resins, like xABS, xPP, and xCE, to elastomeric materials, like xFLEX475 and xFLEX402. With Nexa3D printers, you can confidently explore a broad spectrum of material choices, ensuring your creations are precisely tailored to your requirements.

How Long Does 3D Resin Last?

Some resin manufacturers suggest a shelf life of one year, however, the life of a particular resin can be extended by careful storage and handling. Once in use, resin generally has a limited shelf life, usually being disposable after 6 months.

Use the Best 3D Printer Resins

Resin 3D printers have gained a reputation for their impressive capabilities in producing high-detail parts with a premium surface finish. However, modern resin 3D printers have advanced considerably beyond aesthetics.

With the rise of high-performance materials and cutting-edge technologies, such as Nexa3D’s Lubricant Sublayer Photo-curing Technology, resin parts can now surpass the durability of some of the most widely recognized manufacturing polymers, all while being manufactured at speeds that were previously unimaginable.

Nexa3D offers an array of ultrafast and high-quality 3D printer resins including;

- XiP is the ultrafast 3D printing solution for desktop 3D printing. Powered by the industrial light engine and innovative LSPc membrane technology, the XiP delivers lightning-fast production-grade printing in a compact and user-friendly package.

- XiP Pro sets a new standard for throughput in industrial and dental applications. With an impressive 19.5 liters of build volume and an incredible 7K resolution, you can effortlessly mass-produce hundreds of small nested or large single parts within hours.

- For laboratories, workshops, and production facilities, the NXE 400Pro offers a generous build volume, exceptional accuracy with 4K resolution, and swift printing capabilities, all thanks to our proprietary LSPc® technology.

Ready to experience the power of resin 3D printing yourself?

Want to know more about revolutionary 3D printer resins?