- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

3D printing, or additive manufacturing, has evolved rapidly over the past decades–introducing novel techniques with various applications and benefits. Among these, one technique is gaining increasing recognition for its ability to deliver high-precision prints at impressive speeds: Masked Stereolithography Apparatus 3D printing, also known as mSLA 3D printing.

A generation beyond traditional stereolithography, mSLA 3D printing is used for high-resolution industrial prototyping and production applications. This comprehensive guide will take a deeper dive into the world of mSLA 3D printing. We’ll cover what mSLA is and how it works, what materials it uses, its advantages and disadvantages, and its range of applications. We’ll also compare mSLA with other popular 3D printing techniques, including SLA, DLP, and FDM 3D printing.

Whether you’re a seasoned professional in the 3D printing world or are just curious about this exciting technology, this article will provide you with a thorough understanding of mSLA 3D printing.

What is mSLA 3D Printing?

Masked Stereolithography Apparatus (mSLA) is a form of resin 3D printing that uses a light source to cure a photopolymer resin layer by layer. Similar to Stereolithography (SLA) and Digital Light Processing (DLP), the light in mSLA selectively hardens the liquid resin into the desired 3D shape.

However, what sets mSLA apart is the way the light source works. In mSLA, a digital screen, often an LCD, is used as a mask to shape the light that cures the resin. This masking process allows for the simultaneous curing of entire layers of resin, leading to faster printing speeds–especially for larger models. It also facilitates a high level of precision and detail since the digital mask can control light exposure with exceptional accuracy.

The choice of 3D printing materials, the resolution of the digital screen, the intensity, and wavelength of the light, and the precise control of the z-axis movement all come together to make mSLA a versatile and powerful 3D printing technique.

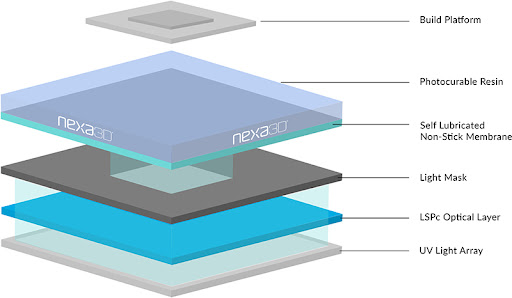

Nexa3D’s unique LSPc® technology, an innovative method that uses UV light to transform photopolymer liquid resin into structural plastic, is at the heart of our mSLA 3D printing offerings. When combined with advanced membrane technology, like the Everlast Membrane, and scalable 4K LCD image masking, this technology provides a highly efficient manufacturing system so users can swiftly move from rapid prototyping to immediate production.

Also from Nexa3D, the Everlast Membrane is a revolutionary interface layer technology designed to surpass the limitations of existing alternative membrane technologies, like clouding, chemical instability, and doming effects. It’s constructed from a highly durable and resilient material and can extend the lifespan of a printer by more than 25 times compared to other available vats and trays. The Everlast Membrane can process over 50,000 layers and manage up to 20 liters of material per membrane, leading to less downtime for membrane replacements and longer continuous runs.

mSLA Materials

The essence of mSLA 3D printing lies in its use of photopolymer resins. These resins are a unique type of polymer that transitions from a liquid state to a solid form in reaction to light. It’s this special property that allows mSLA printers to build highly detailed 3D objects layer by layer. The choice of resin can significantly impact the end result, influencing not just the visual appearance of the printed object, but also its mechanical properties, durability, and functionality.

Standard resins are often used for general prototyping, offering a balanced mix of strength, flexibility, and cost-effectiveness. Tough resins are designed to withstand high stress or strain, making them ideal for parts that need to be durable and resistant to impact, while castable resins burn out cleanly with no residue, perfect for jewelry making and precision casting. Flexible resins can mimic the properties of rubber, while high-temperature resins resist deformation under heat. There are even biocompatible resins that are safe for use in medical and dental applications.

Leading companies in resin 3D printing technology, like Nexa3D, often offer their own ecosystems of materials. Nexa3D provides an extensive selection of resins for its mSLA 3D printers, including PP-Like and ABS-Like, as well as engineering-grade functional materials. Additionally, we provide specialty materials specifically crafted for the creation of high-temperature components.

However, Nexa3D 3D printers have open-material platforms, allowing clients to use proprietary materials developed and validated by partners or third-party manufacturers–as well as materials developed and validated by users themselves.

mSLA Advantages

mSLA 3D printing offers several advantages:

- High detail: mSLA is known for its ability to capture intricate designs with a high level of precision. The resin used in mSLA 3D printing has a high resolution, allowing it to create more intricate designs with sharper edges and finer details.

- Dimensional accuracy: This high-resolution capability also allows for better layer heights, meaning that the layers of the 3D-printed object can be thinner and more precise. It also provides excellent dimensional accuracy, which is critical in industries like engineering and healthcare.

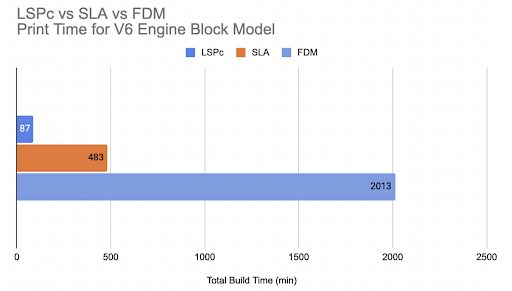

- Speed: Since mSLA cures an entire layer of resin at once, it can often complete prints faster than traditional SLA, particularly for larger models.

- Excellent surface finish: The prints from an mSLA printer often have a smooth and high-quality surface finish. The thinner layers created by the high-resolution resin result in a smoother surface finish.

mSLA Disadvantages

While mSLA 3D printing offers impressive benefits, it’s also important to be aware of its drawbacks. Here are some considerations to bear in mind:

- Costly materials: Photopolymer resins used in mSLA can be more expensive than the materials used in other 3D printing methods. However, while material costs can be a bit higher, printing with resin allows for higher-quality prints at faster speeds–making them well worth the initial investment.

- Handling of materials: The uncured resin and the chemicals used in post-processing can be toxic and should always be handled with care.

- Post-processing: mSLA prints may require a significant amount of post-processing, which can be time-consuming.

Fortunately, the best resin 3D printers can print and cure products much faster. Nexa3D’s XiP printer is designed to overcome the challenges of longer cure times. This breakthrough is achieved through Nexa3D’s proprietary LSPc® technology, which allows for faster layer transitions and minimizes the time spent waiting for individual layers to cure.

The XiP 3D printer from Nexa3D also employs advanced motion systems and optimized curing settings that enhance the overall speed and efficiency of the printing and curing process.

Get a free mSLA 3D printed part.

mSLA 3D Printing Applications

mSLA 3D printing has found a home in various industries and fields due to its high precision and accuracy. Here are some of the key applications of this 3D printing technology:

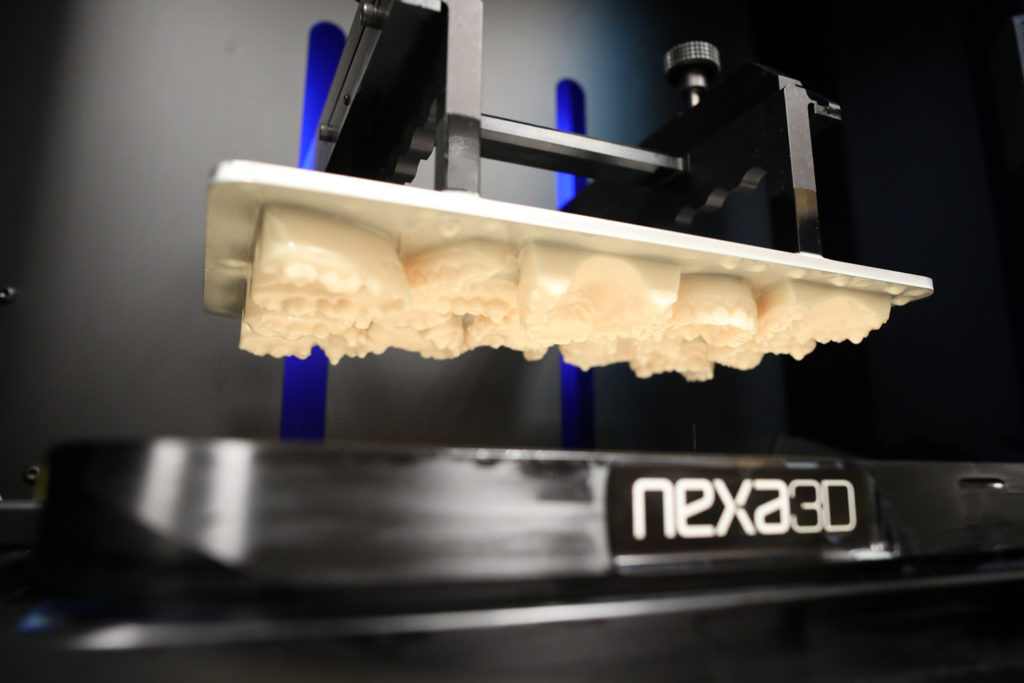

- Dental and medical applications: mSLA’s precision and the availability of biocompatible resins make it a good fit for dental aligners, surgical guides, and other medical devices.

- Automotive aftermarket production: mSLA 3D printing has also revolutionized automotive aftermarket production. For instance, a company like R3D used just a single NXE 400 printer to manufacture 18,000 parts for 1,000 police cars in a year, showcasing the potential of this technology in large-scale production.

- Product prototyping: The excellent surface finish and dimensional accuracy of mSLA prints are beneficial for prototyping and model testing.

- Large-scale 3D printing service providers: Large-scale 3D printing service providers like MTB3D are also benefiting from mSLA technology. Solutions like XiP enable these providers to produce high-quality parts with unmatched throughput and expand their service capabilities and customer base.

- Jewelry design: The high level of detail achievable with mSLA makes it ideal for creating intricate jewelry designs.

- Product packaging: mSLA 3D printing also finds utility in product packaging. For example, PepsiCo used Nexa3D’s xPEEK147 from Henkel Loctite to produce sturdy mold inserts for their packaging needs. The Nexa3D NXE 400 3D printer not only reduced the production time to a mere 12 hours for a complete mold set but the resulting molds could also be used for more than 10,000 bottles before failure.

- Acoustic instruments: Even the music industry is not left untouched by the mSLA revolution. Innovators like Liquid Sound Tech have successfully used engineering material from Nexa3D, such as xCE, to create and extensively stress test acoustic instruments, demonstrating the robustness and versatility of mSLA 3D printing.

- Miniatures and model making: mSLA is increasingly being used to create highly detailed miniatures for tabletop games and model making.

mSLA vs SLA 3D Printing

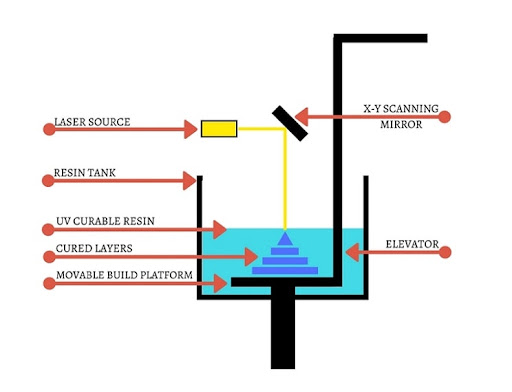

While mSLA and SLA 3D printing both use light to cure a photopolymer resin, they differ in how they deliver this light. SLA employs a laser to trace out each layer, which can sometimes offer a slightly higher level of detail. However, this process is much slower, since the laser has to individually trace every detail of each layer.

On the other hand, mSLA uses a digital screen as a mask to shape the light, allowing it to cure entire layers simultaneously. This process often results in faster print times, particularly for larger models, making mSLA a more efficient choice in most scenarios.

While both technologies have their place, mSLA often comes out ahead due to its blend of detail, speed, and efficiency. If you’re looking for a method that balances precision with time efficiency, mSLA is going to be the superior choice.

mSLA vs DLP 3D Printing

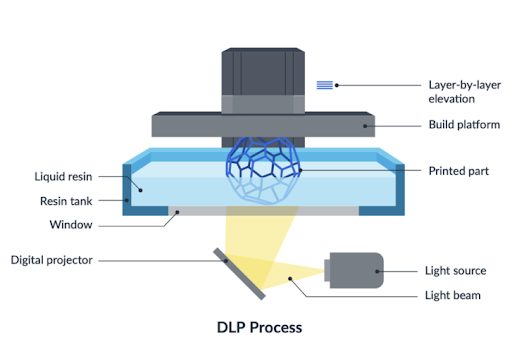

mSLA and DLP are similar in that they both use a digital screen to project light, but they differ in the specifics of their light sources and longevity. DLP typically relies on a more traditional light source, such as a high-powered lamp, and a micromirror array to shape the light. This means that while DLP can deliver high-resolution prints, the light source can degrade over time and require replacement, potentially increasing operational costs.

mSLA, however, utilizes a UV LED light source, which generally has a longer lifespan than traditional DLP light sources. Additionally, when a light source needs replacing, UV LEDs are often less expensive than their DLP counterparts.

While DLP may be suitable for some applications, mSLA often provides a more cost-effective and long-lasting solution. The longevity and cost-effectiveness of its light source make mSLA a compelling option for those seeking to balance quality with long-term operational costs.

mSLA vs FDM 3D Printing

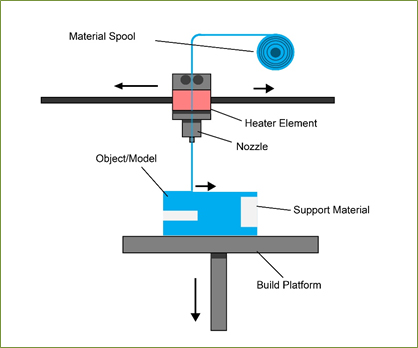

Fused Deposition Modeling (FDM) and mSLA represent two vastly different approaches to 3D printing. FDM builds parts by melting and extruding plastic filament layer by layer. It’s a popular choice for its simplicity and cost-effectiveness, particularly for beginners and hobbyists, but can fall short in terms of precision and surface finish. Its layered construction often results in visible lines on the final print, which may need additional post-processing to smooth out.

mSLA, conversely, uses light to cure a photopolymer resin, allowing for high levels of detail and a smooth surface finish that FDM simply can’t match. Even though the materials for mSLA can be pricier, the quality of the output often justifies the additional cost. Plus, the growing range of resin options, from flexible to high-temperature and even biocompatible materials, make mSLA a highly versatile choice for a broad array of professional applications.

While FDM may be adequate for basic prototypes or hobbyist projects, when it comes to professional applications that demand precision, smooth surface finish, and intricate detailing, mSLA tends to be the superior choice. Its ability to produce high-resolution prints quickly and reliably is proving invaluable across industries, from manufacturing and engineering to design and dentistry.

Use the Best mSLA 3D Printers

mSLA 3D printing offers a unique blend of speed, precision, and quality that stands out among today’s 3D printing technologies. However, to fully leverage these advantages, it’s essential to use the best mSLA 3D printer.

Nexa3D’s 3D printers take the best of mSLA technology–and then go a step further. With advanced features including LSPc® technology, the Everlast Membrane, and scalable 7K LCD image masking, Nexa3D’s mSLA 3D printers provide unparalleled performance in additive manufacturing.

Experience the power of mSLA 3D printing today.