- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

From creating intricate jewelry to printing human organs for medical research, the applications of 3D printing are endless. Resin 3D printing specifically is ideal for producing complex parts and components with extraordinary detail.

This article will delve into the exciting possibilities of resin 3D printing and provide a review of the best resin 3D printers on the market.

What Is Resin 3D Printing?

Resin 3D printing is a vat photopolymerization form of additive manufacturing that uses liquid resins to create objects layer-by-layer. A light source cures liquid resin, solidifying it in layers until the entire product has been printed.

Due to the thin layers and precision of the light, resin 3D printers can produce models with higher detail, accuracy, and a smoother finish than other 3D printing technologies.

Since Charles Hull invented the first resin-based 3D printer in 1984, the technology has come a long way. Several generations of resin 3D printing technology have been developed, including Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (mSLA).

Each emerging technology significantly improves over its predecessor and broadens the range of objects for 3D printing. mSLA, the latest generation of SLA 3D printing, uses masks to control where light reaches the build plate. Masked light ensures that only specific areas are exposed to the light, allowing for highly detailed prints that can be printed faster than traditional SLA printers.

Since it projects pixels straight on, it creates more consistent parts from edge to edge. Plus, the LCD panels used in this process are much more readily available than DLP chips–and at resolutions of 8k and beyond. This leads to overall faster printing speed and reduces the cost of producing objects.

Resin 3D Printing vs. 3D Printing with Filaments

Fused Deposition Modeling (FDM) 3D printing uses heated plastic or metal filaments to produce objects layer by layer. The printer feeds a solid polymer filament into an extruder assembly where a motor drives it through a thermal core. The materials heat close to their melting point before they are extruded onto a build plate through a nozzle. The melted materials are deposited layer-by-layer until the entire object is formed.

Though it’s a popular 3D printing technique, there are some drawbacks to filament 3D printers. They can’t print with the same level of quality and detail as resin 3D printers, and they tend to print much more slowly than resin printers.

Resin 3D printing can also produce more accurate and detailed objects than filament 3D printing. The thinner layers and precision of the light result in smoother surfaces with higher resolutions. Due to the liquid nature of resins, they can create complex shapes or internal structures that are impossible to make with filaments.

Download the Guide

Choosing Between Filament and Resin 3D Printers

We’ve curated this guide specifically to assist you in making your decision between the resin 3D printer and the filament 3D printer.

Resin 3D Printing vs. PLA

Polylactic Acid is one of the most common 3D printing filaments used in Fused Filament Fabrication (FFF) 3D printing. Unlike resin 3D printing, which uses a liquid photopolymer, PLA filament 3D printing utilizes molten plastic that is extruded in layers.

Compared to printing with resin, PLA filaments do not produce as accurate or as detailed objects.

Best resin 3D Printers at-a-glance

While there are several resin 3D printers in the market, some of the best printers include:

- Nexa3D XiP Pro: The XiP Pro by Nexa3D is a powerful industrial resin 3D printer that offers the highest production throughput at the lowest cost of production. It packs a punch with an impressive 19.5L build volume, fast print speed, and advanced LSPc technology for exceptional print quality and unbeatable surface finish

- Nexa3D XiP: A professional desktop printer, the Nexa3D XiP prints 3D models at a speed up to 10 times faster than many popular resin printers. It comes with a compact 4.8L print volume and the patented LSPc technology for exceptional print speed, quality, and surface finish

- Nexa3D NXE 400Pro: The NXE 400 Pro is an industrial-grade 3D with a large 17L build volume, incredible provision, and an open material platform to process various resin materials. It offers a higher part throughput and 6.5x more speed than many printers in the market

- Anycubic Photon M3 Plus: It is a resin 3D printer with a 5.9L print size measuring 245 x 197 x 122 mm and a print speed of about 100 mm/hour

- Phrozen Sonic Mega 8K S: Offers a 15-inch build plate, fast print time, and features like a lift-up lid for print comfort

- Prusa SL1S Speed: This is based on mSLA technology and comes with a tilting resin VAT, a monochrome LCD, and a sensitive resin VAT sensor

- Creality Halot-One Plus: The Halot-One Plus is an industrial-grade printer that works with 405NM UV resin

- Formlabs Form 4: This is another evolution of Formlabs’ first-generation laser-based system.

- Elegoo Jupiter: It is a large-format resin 3D printer with an all-metal structure and the ability to print detailed large models

- Hunter DLP Printer: Has a build volume of 120 x 67.5 x 150 mm and uses a DLP projector to cure layers of resin

- Phrozen Sonic Mini 8K: Comes with a 7.1-inch mono LCD screen and an LED module with linear projection as its light source

- 3D Systems SLA 750: A large 3D printer with a 750 × 750 × 550 mm build volume and a complete ecosystem of automation, processing, and smart software

- Carbon M3 Max: Has a build volume of 307 x 163 x 326 mm and uses the continuous liquid interface production technology to produce thermoset parts from resin feedstock

- Stratasys Origin One: An industrial photopolymer 3D printer used for mass production of end-use parts from a wide range of resin materials

- Elegoo Saturn S: Has a build volume of 196 x 120 x 210 mm and is used by both enthusiasts and professionals alike

We’ll go into more detail on each of these resin 3D printers below.

How do resin 3D printers work?

Resin 3D printing is a vat photopolymerization form of additive manufacturing that uses liquid resins to create objects layer-by-layer. A light source cures liquid resin, solidifying it in layers until the entire product has been printed.

Due to the thin layers and precision of the light, resin 3D printers can produce models with higher detail, accuracy, and a smoother finish than other 3D printing technologies.

Since Charles Hull invented the first resin-based 3D printer in 1984, the technology has come a long way. Several generations of resin 3D printing technology have been developed, including Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (mSLA).

Each emerging technology significantly improves over its predecessor and broadens the range of objects for 3D printing. mSLA, the latest generation of SLA 3D printing, uses masks to control where light reaches the build plate. Masked light ensures that only specific areas are exposed to the light, allowing for highly detailed prints that can be printed faster than traditional SLA printers.

Since it projects pixels straight on, it creates more consistent parts from edge to edge. Plus, the LCD panels used in this process are much more readily available than DLP chips–and at resolutions of 8k and beyond. This leads to overall faster printing speed and reduces the cost of producing objects.

Resin 3D Printing vs. 3D Printing with Filaments

Fused Deposition Modeling (FDM) 3D printing uses heated plastic or metal filaments to produce objects layer by layer. The printer feeds a solid polymer filament into an extruder assembly where a motor drives it through a thermal core. The materials heat close to their melting point before they are extruded onto a build plate through a nozzle. The melted materials are deposited layer-by-layer until the entire object is formed.

Though it’s a popular 3D printing technique, there are some drawbacks to filament 3D printers. They can’t print with the same level of quality and detail as resin 3D printers, and they tend to print much more slowly than resin printers.

Resin 3D printing can also produce more accurate and detailed objects than filament 3D printing. The thinner layers and precision of the light result in smoother surfaces with higher resolutions. Due to the liquid nature of resins, they can create complex shapes or internal structures that are impossible to make with filament.

Resin 3D Printing vs. PLA

Polylactic Acid is one of the most common 3D printing filaments used in Fused Filament Fabrication (FFF) 3D printing. Unlike resin 3D printing, which uses a liquid photopolymer, PLA filament 3D printing utilizes molten plastic that is extruded in layers.

Compared to printing with resin, PLA filaments do not produce as accurate or as detailed objects.

Best Resin 3D Printers

Here is a review of some of the best resin 3D printers in the market:

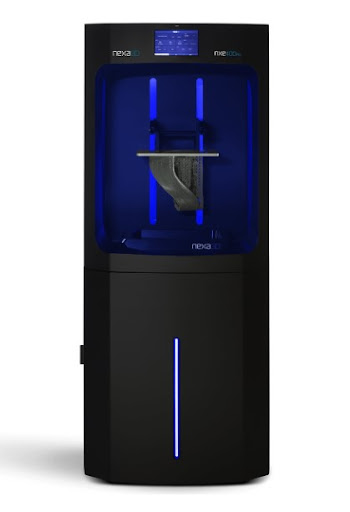

1. Nexa3D XiP Pro

The Nexa3D XiP Pro is an industrial resin 3D printer that delivers the highest production throughput at the lowest cost of operation. XiP Pro offers the largest 19.5L build volume and fastest print speed in its class–and its unrivaled productivity allows you to produce functional prototypes and final-use parts at previously unattainable production economics.

The Nexa3D XiP Pro 3D printer uses the patented LCD-based LSPc print technology to provide unprecedented production value, producing 3D structures with excellent print quality and surface finish. The printer is equipped with a cutting-edge 10-inch 7K resolution LCD screen, an advanced sensor package, adaptive layer-by-layer printing technology, an environmental monitoring system, and a debris detection function, all within a Billet Aluminum enclosure.

With an open platform that supports a wide range of manufacturing materials ranging from strong and durable resins, like xABS, xPP, and xMOLD to elastomeric materials, like xFLEX475 and xFLEX402, XiP Pro is a forerunner when it comes to manufacturing, prototyping, and digital dentistry.

Various industries use XiP Pro printers for their manufacturing needs. Glen Mason, Manager of Advanced Innovation/Industrialization at DeMarini, a division of Wilson Sporting Goods, explained: “XiP Pro gives us about 10x the throughput of what we had before. Nexa3D has done a really great job taking the costs out of 3D printing while increasing the capacity. Their printers are getting bigger, faster, and more affordable at the same time. It’s a total win for the users.”

Best for: Professional engineers and designers who need rapid iteration prototyping or small businesses who need low volume production.

Get a free sample part from the Xip Pro

2. Nexa3D NXE 400Pro

The Nexa3D NXE 400Pro is an industrial-grade 3D printer that offers high throughput, low operational costs, and incredible precision. It has a 17L build volume, ultrafast speeds and uses patented Lubricant Sublayer Photo-curing (LSPc®) technology to deliver accuracy with a superior surface finish. It can accommodate a range of materials including polypropylene, acrylonitrile butadiene styrene and other functional materials.

The NXE 400Pro is used for industrial applications, rapid prototyping, and consumer products. For example, iconic brand PepsiCo found the quick speeds and high throughput of the NXE 400 3D printer–accompanying material performance–is ideal for producing the mold components it needs. The NXE 400Pro allowed for up to a 96% cost reduction compared to traditional metal tooling.

Best for: Production and on-demand manufacturing and functional prototypes.

Request a NXE 400Pro sample part.

3. Nexa3D XiP

The Nexa3D XiP is a professional desktop resin 3D printer that uses a patented Lubricant Sublayer Photocuring technology to achieve ultra-fast printing speeds. It combines a compact footprint with a 4.8L print volume and fast print speed to deliver high-quality prototypes on your desktop.

The Nexa3D XiP printer allows parts to print up to 10 times faster than other leading 3D printers on the market. Its LSPc® technology has a self-lubricated membrane that eliminates the forces between the parts being printed, enabling faster print speed without sacrificing the print quality or surface finish. The XiP is also affordable, with printing packages starting at $6995.

The XiP is used by professionals for engineering, designing, and manufacturing. Liquid Sound Technologies, a business that develops sound-enhancing accessories for acoustic instruments, used the XiP 3D printer for its patented product, the Droplet Sound System. This partnership enabled them to print a batch of 60-70 pieces in less than 30 minutes and cut production costs by up to 90%.

With this unprecedented performance, the Nexa3D XiP easily won the 3D Printing Industry Awards for Desktop non-FFF 3D Printer of the Year in 2023.

Best for: Professional engineers and designers who need rapid iteration prototyping or small businesses who need low-volume production.

Ready to experience the XiP in action?

4. Anycubic Photon M3 Plus

![]()

The Anycubic Photon M3 Plus is a desktop resin 3D printer with quick print times, and large build plate size. It has a 5.9L print size measuring 245 x 197 x 122 mm and a print speed of about 100 mm/hour.

This device comes with a 6K LCD resolution, laser-engraved aluminum alloy printing platform, 5-inch resistive touch screen control panel, smart resin filling, and an open material platform that can accommodate different materials, including specialty and advanced resins.

Best For: Hobbyists and small-volume part production.

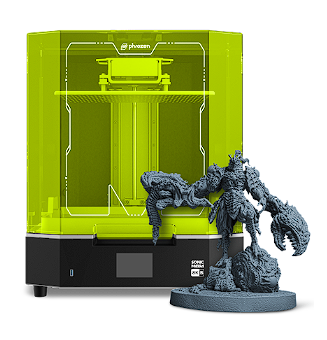

5. Phrozen Sonic Mega 8k S

Phrozen Sonic Mega 8K S is a professional desktop resin 3D printer with a print volume of 33 x 18.5 x 30 cm (330 x 185 x 300 mm). It has a large 15-inch build plate, a 3.5-inch Touch Panel, and an all-metal built-in drip hanger to save every last drop of resin after print.

The Phrozen Sonic Mega 8k S offers energy-efficient LED lighting and a wide range of temperatures so it can print with high-temperature materials like ABS, ASA, and Polycarbonate.

Best For: Model making and printing detailed parts and small-scale miniatures.

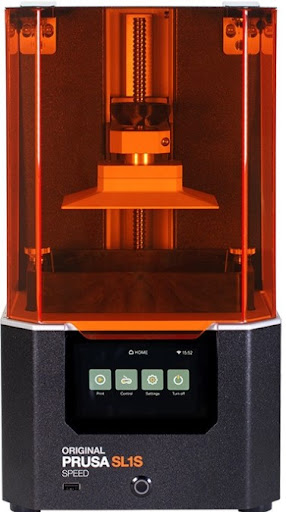

6. Prusa SL1S Speed

The Prusa SL1S Speed is based on mSLA printing technology, using a high-resolution LCD panel and a UV LED array to cure thin layers of resin to achieve unprecedented detail. It has a build volume of 127 × 80 × 150 mm, a 5.96-inch LCD resolution, and a large build plate with considerably fast print times.

The Prusa SL1S Speed comes equipped with several features, including a quick-release platform, advanced LCD cooling system, carbon filter, a fully-featured network interface, and silent operation using an auto-homing function. The printing platform supports UV-sensitive liquid resin and long-exposure materials

Best For: Rapid prototyping, designing, and manufacturing detailed models and objects.

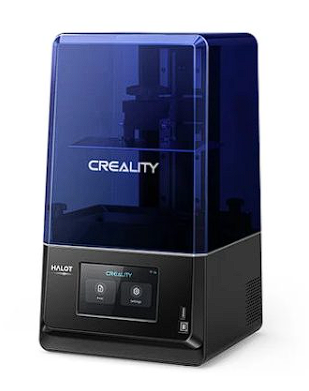

7. Creality Halot-One Plus

Creality Halot-One Plus is an industrial-grade resin 3D printer that can print large, detailed models with a build volume of 172 x 102 x 160 mm. It has an LCD resolution of 4K and a physical size of 310 × 300 × 530 mm. Its embedded temperature control system helps ensure consistent printing conditions.

Best For: Large-scale industrial 3D prints and end-use production parts.

8. Formlabs Form 4

Formlabs Form 4 is an industrial 3D printer that uses masked stereolithography technology. It has a build volume of 200 x 125 x 210 mm (5.25 liters) and a print speed of 40 mm/hour across all materials. The Formlabs Form 4 3D printer comes with an Intelligent Control System, a 7-inch interactive touchscreen, sensors to control printing efficiency, an open material platform that prints 23+ different materials, including third-party materials.

Best For: Producing 3D prototypes.

9. Elegoo Jupiter

The Elegoo Jupiter 3D Printer is an all-metal structure with a build size of 277.848 x 156.264 x 300 mm and a 5-inch capacitive touchscreen interface. It has automatic resin feeding, a 286 x 168 mm mask LCD, and a printing speed between 30 and 70 mm/h.

The Elegoo also comes with a 12.8-inch mono screen and a large fan for heat dissipation. It uses mSLA technology to print resins with different features, ranging from water-washable to standard, ABS-like, and plant-based.

Best For: Creating mid-size to large resin prints.

10. Hunter DLP Printer

The Hunter DLP Printer by Flashforge functions with Digital Light Processing technology, using uniform, continual, and stable LED lighting to accurately create 3D-printed models. It has a build volume of 120 x 67.5 x 150 mm, a positioning accuracy of 1920 x 1080 pixels, and a 10 mm/h build speed. The printer has a 3.5-inch touchscreen, a special precision compensation algorithm, removable aluminum resin VAT and FEP films, and multiple 3d model transfer options,

The Hunter DLP printer is compatible with multi-brand photopolymer resins, including Flashforge Hunter prints like FH1100 Castable Resin, FH1400 Tough Resin, and third-party 3D printing resins.

Best For: Small-scale manufacturing.

11. Phrozen Sonic Mini 8K

Phrozen Sonic Mini 8K is a professional-grade resin 3D printer with an 8K LCD screen and a build volume of 165 x 72 x 180 mm. It has an 18 cm Z- axis and 8K LCD screen, making intricate miniature printing better. The 3D printer has a physical dimension of 299 x 299 x 430 mm and weighs 13kg.

Best For: Model making and printing detailed parts and miniatures.

12. 3D Systems SLA 750

3D Systems SLA 750 is a production-grade resin 3D printer for industrial applications. This device has a build volume of 750 × 750 × 550 mm and it comes with an automatic calibration system, self-monitoring capabilities, and open platform support.

Best For: Industrial materials like mandrel tooling cores and aids for large cooling ducts, pipes, and manifolds.

13. Carbon M3 Max

Carbon M3 Max is a production-grade resin 3D printer for producing end-use parts. It has a build volume of 307 x 163 x 326 mm, a light engine of 4K, and it runs on an open platform for various materials. It uses a Digital Light Synthesis™ technology process to lower forces on the part.

Best For: Printing elastomeric parts and parts with features that are more sensitive to high forces.

14. Stratasys Origin One

Stratasys Origin One is an industrial-grade resin 3D printer for end-use production. It has a build volume of 192 x 108 x 370 mm, a proprietary P3™ Programmable Photopolymerization technology, and it uses optics to ensure detailed prints. This DLP 3D printer’s synchronized print process includes pneumatic controls to reduce pull forces during the print process.

Best For: Industrial-grade printing and mass production of resin-based consumer parts.

15. Elegoo Saturn

Elegoo Saturn S 3D printer is part of the Saturn series with a build volume of 196 x 120 x 210 mm and runs on an open platform. It has a USB-powered charcoal-filled air filter and a 9.1-inch 4K mono display with 4098 x 2560 pixels. The Elegoo Saturn S supports various resin materials and offers good print speed and accuracy.

Best For: Mid-sized to large prototyping.

What to Consider When Buying a Resin 3D Printer

Resin printers have no doubt revolutionized the process of manufacturing across several industries. However, when purchasing a resin 3D printer, it is important to consider several factors to ensure you select a 3D printer that fits your production needs. Some of these factors include:

1. Your Resin 3D Printing Application

Understanding the specific purpose for which you need a resin 3D printer is a great way to know which printer is the best fit for your production needs. Whether it is for creating jewelry, creating prototypes, manufacturing jigs and fixtures, or for more industry-specific purposes like dental solutions, knowing your application will help you narrow down your options and guide you in choosing a printer that best suits your needs.

2. Desktop vs. Industrial 3D Printing

3D printers can be categorized into two distinct types which are desktop and industrial printers. While both categories are used in resin 3D printing, they have vastly different specifications, such as printing sizes and capabilities, factors that determine their application.

Desktop 3D printers are compact and more affordable, making them a great option for hobbyists or professionals with smaller printing needs. Industrial 3D printers are larger and more expensive, often offering more advanced features in terms of printing speed and capability, making them perfect for professional applications and mass production.

3. Print Speed & Quality

Choosing a resin 3D printer with fast printing speed and superior printing quality is challenging for manufacturers, as many printers often sacrifice print speed for precision. However, powerful 3D printers like Nexa3D XiP and XiP Pro deliver both speed and superior quality using the state-of-the-art LSPc® technology that uses a self-lubricated membrane to optimize the curing process.

With the LSPc® technology, the Nexa3D XiP and XiP Pro resin 3D printers deliver unmatched speed without trading off print quality or surface finish.

4. Resin Materials

The type of resin material you use during 3D printing impacts the properties of your printed structures, including surface quality and durability. Since resin printers usually have different resin material compatibility, it’s important to choose a printer with an open platform such as Nexa3D XiP, XiP Pro, and NXE 400PRO with a broad material selection that allows you to process a wide range of resin materials.

5. Resin 3D Printer Cost

The cost of a resin 3D printer is also an important factor to consider when looking to purchase one. This not only includes the cost of purchasing and installing the printer but also the running costs that go into printing 3D models and performing maintenance.

While desktop printers are generally more affordable than industrial resin printers, it is important to remember that they offer very different functions. Hence, it is best to determine your budget and choose a printer that offers the best value in terms of functions, features, and print quality.

6. Post-processing Needs

Post-processing needs are another essential factor to consider when choosing a resin 3D printer. Resin prints typically require post-processing efforts that range from washing the parts to curing, support removal, and sanding and smoothing.

These processes can be time-intensive and require additional equipment that may increase printing expenses. That’s why it’s so critical to choose printers that minimize post-processing needs, such as those that have a built-in UV curing chamber and those with high printing detail.

More About the Best Resin 3D Printers

Getting a resin 3D printer to match your printing needs is ideal when choosing a resin printer. Some more information you need to know before choosing a resin 3D printer include:

Best Resin 3D Printer for Miniatures

When choosing a resin 3D printer for beginner-level, miniature printing projects, consider the Phrozen Sonic Mega 8k or Elegoo Mars 3.

If you’re looking to print miniatures for professional purposes, the Nexa3D XiP 3D printer is a great option. With a build volume of 4.8L and its use of LSPc® technology, Nexa3D XiP offers accuracy, precision, and the ability to print models with the finest surface finishing.

Best Resin 3D Printer for Beginners

If you’re a hobbyist starting your experience with 3D printing, consider the Anycubic Photon M3 Plus or Formlabs Form 4.

Large Resin 3D Printer

If you’re looking for larger 3D printers for bigger resin projects, Nexa3D’s XiP Pro and the NXE 400Pro are great options for large-scale manufacturing. The XiP Pro boasts a massive 19.5 build volume, while the NXE 400Pro boasts an equally large 17L build volume.

FAQs on Resin 3D Printing

Let’s take a look at some helpful information on resin 3D printing and resin 3D printers.

What is Resin 3D printing best for?

Resin 3D printing is best for models and products that require high accuracy, detail, and resolution. It is also ideal for producing end-use parts with a smooth finish. Many industries, such as automotive, medical, and aerospace, use resin 3D printing for rapid prototyping.

For instance, MotoCillino, an Italian automotive company, is using Nexa3D’s XiP 3D printer to accelerate its design iteration and validation for car part production. The company has reduced its lead time by up to 90% and improved product quality using this advanced resin 3D printing technology.

Is a resin 3D printer better?

Resin 3D printers are known for their superior and high-detail accuracy in capturing very fine details on printed models. However, the quality of a resin printer depends on the 3D printer being used. With resin 3D printers such as Nexa 3D, you can achieve exceptional precision and accuracy, producing intricate and detailed prints with unparalleled quality and surface finish.

Benefits of resin 3D printers

Resin 3D printers offer the following benefits:

- High detail accuracy for printing intricate models

- Superior surface quality

- Faster prototyping

- Versatility due to the ability to print different resin materials

- Cost-effectiveness compared to traditional methods like CNC machining

Is resin 3D printing good for beginners?

Resin 3D printing is a considerably great option for beginners who want to create miniature or small-sized intricate and detailed resin structures. This is because resin 3D printing is suited for creating complicated designs, prints with higher resolution and detail, experimenting with resin materials with different unique material properties, and producing structures with smoother surface finish.

How long does 3D resin last?

3D resin has a shelf life of around 12 months when unopened and stored properly in a dark place and at cool temperatures. It is important to store resin properly according to manufacturers’ directions, as old, expired resin is likely to produce failed parts.

In terms of the lifespan of printed parts, the longevity of 3D-printed resin structures depends on the specific resins used and the conditions in which they are used.

Is resin stronger than plastic 3D printing?

Yes, resin prints typically have stronger mechanical properties than PLA prints. This is because the process of solidifying liquid resin layer by layer results in a smooth surface finish and high accuracy. Some specialty resins have unique material properties like translucency, flexibility, and better temperature resistance not typically available to many plastics.

What is resin 3D printing best for?

Resin 3D printing is best for models and products that require high accuracy, detail, and resolution. It is also ideal for producing end-use parts with a smooth finish. Many industries, such as automotive, medical, and aerospace, use resin 3D printing for rapid prototyping.

For instance, MotoCillino, an Italian automotive company, is using Nexa3D’s XiP 3D printer to accelerate its design iteration and validation for car part production. The company has reduced its lead time by up to 90% and improved product quality using this advanced resin 3D printing technology.

Choose the Best Resin 3D Printer

While all printers on our list have unique features that place them at the top in the resin 3D printer market, printers like Nexa3D XiP, XiP Pro, and NXE 400Pro stand out for being a true workhorse, delivering unparalleled production throughput, speed, and efficiency.

If you’re ready to experience the power of ultrafast resin 3D printing, request a free sample part from Nexa3D. With a lineup that includes a wide range of high-quality 3D printers, such as the XiP, NXE 400Pro, and XiP Pro, printers can get the highest-performing 3D printing system for their needs.

Resin 3D Printing Resources

Resin 3D Printing Guide

Before attempting 3D printing as a beginner, it is important to become familiar with the concept of resin 3D printing, the types of resins, the printing process, and necessary post-processing techniques. Learn more about the resin 3D printing process in the ultimate guide to resin 3D printing.

Resin 3D Printing Materials

There are various types of resin 3D printing materials, all with different characteristics that determine the properties of the resin models printed. Learn more about the various resin 3D printing materials and their uses across various industries.

Clear Resin 3D Printing Guide

Clear resin 3D printing is an advanced process that uses transparent photopolymers to create detailed 3D-printed structures with a high degree of clarity and translucency. Learn more about the process in this guide to clear resin 3D printing.

What is Photopolymer Resin?

Photopolymer resin is a light-sensitive polymer that changes its properties when exposed to light, most commonly ultraviolet light. This type of resin includes monomers, oligomers, photoinitiators, and additives.

Learn more about photopolymer resins

SLA Resin 3D Printing

Short for Stereolithography Apparatus, SLA resin 3D printing is a form of vat photopolymerization resin 3D printing technique that produces objects by selectively curing photopolymer liquid resin layer by layer through light-activated polymerization.

In SLA 3D printing, the builder focuses a laser beam of UV light on the free surface of a photosensitive liquid in a point-to-point sequence. As a set of galvanometers reflects the UV light onto the photopolymer resins, the photopolymer resin is solidified into layers of the model being created.

Find more details and explore the world of SLA resin 3D printing in Nexa3D’s in-depth guide on SLA 3D Printing.