- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Finding the right 3D printer for your business can significantly enhance your productivity and profitability. With the market brimming with various 3D printers offering unique features and capabilities, choosing the right one can be difficult.

In this guide, we’ll explore a wide range of options of 3D printers ranging from budget-friendly desktop printers to the more sophisticated industrial options, all across different printing technologies. So, if you’re interested in staying up-to-date with the latest developments in 3D printing technology–and the best 3D printer options for this year–keep reading.

Download the Guide

Table of Contents

- Best 3D Printers: desktop, industrial, and more

- 1. XiP Pro: Best industrial resin 3D printer for fast print speeds

- 2. Nexa3D XiP: Best 3D Printer for Desktop Resin 3D Printing

- 3. Nexa3D NXE 400Pro: Best Resin 3D Printer for Industrial & Dental Applications

- 4. Nexa3D QLS260: Best SLS 3D Printer for Fast SLS Printing

- 5. Nexa3D QLS230: Best SLS 3D Printer for Economical SLS Printing

- 6. Nexa3D HSE™ 180 Series: Fastest filament 3D printer

- 7. Nexa3D HSE™ 280i: Best dual extrusion filament 3D printer

- 8. Nexa3D QLS820: Best SLS 3D Printer for High-Throughput Manufacturing

- 9. Formlabs Form 4: Best Budget Desktop 3D Printers for Prototyping Beginners

- 10. Creality Ender 3 V2 Neo: Best FDM Desktop 3D Printer

- 11. Ultimaker S3: Best Desktop Metal 3D Printer

- 12. 3D Systems ProX SLS 6100: Best 3D Printer for Large Projects

- 13. Stratasys F370: Best Industrial FDM 3D Printer

- 14. Markforged X7: Best carbon fiber 3D printer

- 15. PRUSA Mini+: Best budget 3D printer with color

- 16. Bambu Lab A1 Mini: Best 3D printer for beginners

- 17. Creality Ender 3 V3 KE: Fastest budget 3D printer

- Differentiating between the best 3D Printers

- More 3D Printer Picks

- How to Choose the Best 3D Printer

- Choose the Best 3D Printer for Your Additive Manufacturing Projects

Technical Review of LSPc®

Unleash your manufacturing potential with this guide, which explores the limitations of traditional SLA, offers a technical overview of Lubricant Sublayer Photo-curing (LSPc), and shows you how to achieve up to 20x productivity gains.

Best 3D Printers: desktop, industrial, and more

There are a variety of desktop and industrial printers in the market today, each with its unique specifications and capabilities. Some of the best 3D printers include:

1. XiP Pro: Best industrial resin 3D printer for fast print speeds

Nexa3D XiP Pro is an industrial resin 3D printer that delivers the highest production throughput at the lowest cost of operation. XiP Pro offers the largest 19.5L build volume and fastest print speed in its class–and its unrivaled productivity allows you to produce functional prototypes and final-use parts at previously unattainable production economics.

Various industries use XiP Pro printers for their manufacturing needs. According to Glen Mason, Manager of Advanced Innovation/Industrialization at DeMarini (a division of Wilson Sporting Goods), “XiP Pro gives us about 10x the throughput of what we had before. Nexa3D has done a really great job taking the costs out of 3D printing while increasing the capacity. Their printers are getting bigger, faster, and more affordable at the same time. It’s a total win for the users.”

3D Printer Specifications:

- 19.5L build volume & 10″ High-Resolution LCD Touchscreen

- Industry-leading print of up to 24 vertical cm per hour

- 7K resolution LCD screen with 46 µm pixel size and 23 µm sub-pixel resolution

- 10″ High-Resolution LCD Touchscreen

- Lubricant Sublayer Photocuring (LSPc) technology

- Advanced sensor package and adaptive layer-by-layer printing technology

- Open material platform with print resolution of 25 µm – 200 µm

Pros:

- Large industrial capacity and compact footprint

- Intuitive NexaX 3D printer software & Smart Resin Delivery System

- Environmental Monitoring System

- LCD-based VAT photopolymerization process uses patented Lubricant Sublayer Photocuring (LSPc) technology

- Self-lubricating membrane enables lighting-fast print speed and unprecedented production value without sacrificing print quality or surface finish

- Open material platform (ability to use with third-party resins)

Cons:

- Not for hobbyist 3D printing

- Onlyused for resin 3D printing processes

- Best For: Prototypes and production applications for engineering, dental, and other industries.

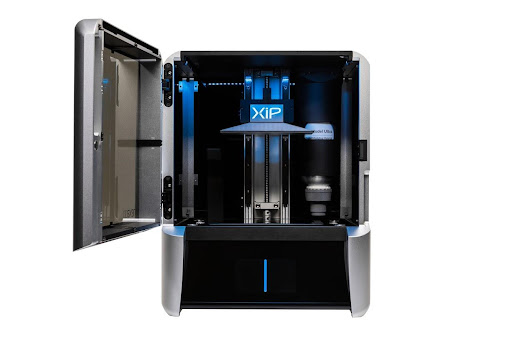

2. Nexa3D XiP: Best 3D Printer for Desktop Resin 3D Printing

Nexa3D makes ultrafast resin 3D printers for designers, engineers, and manufacturers who need to develop and create the products of tomorrow. One of Nexa3D’s fastest printers is the Nexa3D XiP high-performance printer.

The XiP combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes for any desktop. It’s patented under Nexa3D’s Lubricant Sublayer Photo-curing (LSPc) technology, which has successfully solved the historical speed vs. quality problem. This technology addresses common concerns over usable power, image homogeneity, heat buildup, layer separation, and resin replenishment cycles during the build process.

The Nexa3D XiP printer also has a build time of about 87 minutes, which allows parts to print up to 10 times faster than other leading 3D printers on the market. XiP is also affordable, with printing packages starting at $6995.

If you are looking for speed, precision, and reliability, the XiP printer is the right choice for you.

Pros:

- Allows users to print at speeds of up to 180 mm per hour.

- Large build volume of 4.8L.

- Provides ultimate flexibility to materials needed.

- Easily upgradeable.

- Easy to operate.

- Open material platform (ability to use with third-party resins).

- Comes with in-built wash packages for post-process.

- Produced from aluminum materials, making it recyclable.

- Modular design.

Cons:

- It’s best for professional printing, not hobbyist printers.

Best for: Prototypes and production-grade applications for engineering, dental, and other industries.

3. Nexa3D NXE 400Pro: Best Resin 3D Printer for Industrial & Dental Applications

The Nexa3D NXE 400Pro is a top-tier industrial 3D printer designed for professionals who require speed and precision in their printing. The photopolymer 3D printer boasts an unprecedented 17L build volume, delivering ultrafast speed and throughput without compromising its print accuracy.

The NXE 400Pro industrial 3D printer has an inbuilt patented Lubricant Sublayer Photo-curing (LSPc®) technology that delivers the required accuracy and tolerances with a superior surface finish for any mSLA 3D printing job. Also, the NXE 400Pro industrial 3D printer has one of the best use cases across various industries like automotive, aerospace, and more.

3D Printer Specifications:

- 17L build volume

- High-resolution pixels of 76.5 µm

- 6.5x print speed of standard industrial resin 3D printers

- Open material platform with broad material selection

- 7K (6480 x 3600) max resolution with a pixel size of 46 µm (0.0018 in)

Pros:

- Ultrafast photopolymer industrial 3D printer.

- Unmatched 17-liter build volume (274 x 155 x 400 mm).

- Best in its class for print speeds (6.5x faster than other SLA and DLP technology).

- LSPc light engine delivers uniform, high power, and distortion-free image to ensure part-to-part accuracy and uniformity.

- A self-lubricated membrane that prevents delamination forces and enables fast print speeds.

Cons:

- This is also a professional printer (not for hobbyists).

Best for: Production and on-demand manufacturing and functional prototypes.

4. Nexa3D QLS260: Best SLS 3D Printer for Fast SLS Printing

The Nexa3D QLS 260 is a ground-breaking open platform SLS 3D printer designed to offer unprecedented production capabilities. This advanced printer offers an industry-leading cycle time of just 21 hours with a maximum required cooling period of 2 hours, making it a powerhouse compared to other standard SLS 3D printers. It features a build volume of 230 x 230 x250mm and a build speed of up to 22 mm/hour. It is ideal for businesses and manufacturers seeking to accelerate their production timelines, reduce costs, and create high-performance parts with uncompromising quality.

The QLS 260 uses a single 60-watt CO2 and an open material platform to print16+ qualified high-temperature thermoplastics and metal materials. This large 3D printer manipulates materials like PP, PBT, and TPU into prototypes and production parts with robust mechanical and thermal properties. In addition to these materials, the QLS 260 prints recycled waste powder from other technologies, such as multi-jet fusion and third-party materials.

The QLS 260 has one of the lowest entry points in the professional SLS printing market. Thanks to a powder refresh rate of just 20% and its use of third-party materials, it combines unparalleled production capabilities with lower operating costs, making it the fastest 3D printer with the lowest cost of ownership in the market.

3D Printer Specifications:

- 230 x 230 x250mm build volume

- Open material platform compatible with 16+ qualified materials, including third-party materials

- Build speed of up to 22 mm / hour (Geometry dependent)

- Printer Dimensions of 148 x 85 x 204 cm (58.3 x 33.5 x 80.3 in)

- Later thickness of 0.06 / 0.08 / 0.1 / 0.15 / 0.2 / 0.3

- 20% powder refresh rate and ability to recycle used powder

- Powered by two advanced software suites, NexaX for QLS

- On-board nitrogen generator

Pros:

- Limitless open-material platform that is compatible with a range of materials, including third-party materials and recycled waste powder

- Industry-leading cycle time of 21 hours allows for high daily throughput

- Lowest total cost of ownership for industrial SLS 3D printing needs

Cons:

- Only suitable for processes requiring SLS technology

Best for: High-volume production of parts with robust properties in various materials like PBT and third-party materials.

Learn more about the QLS 260 3D printer.

5. Nexa3D QLS230: Best SLS 3D Printer for Economical SLS Printing

The QLS 230 is the most affordable open-platform SLS printer suitable for industrial use. It offers a swift 24-hour cycle speed to increase production while creating high-quality prints out of a wide range of quality materials.

Featuring a generous build volume of 230 x 230 x 230 mm (9.1 x 9.1 x 9.1 inches), the QLS 230 offers ample space for producing large parts or multiple smaller parts simultaneously. Its impressive build speed of up to 20 mm/hour ensures rapid production, allowing users to create high-quality parts efficiently.

The QLS 230 has an open material platform and a single 30W laser for processing 10+ qualified nylon and fusion materials into prototypes or final-use products with robust mechanical properties. In addition, the QLS 230 supports recycled powders from HP® and EOS for ultimate operational and manufacturing sustainability in both polymer and metal part production.

The Nexa3D QLS is another advanced printer in the Nexa3D series that boasts the lowest entry point within its class due to its 20% powder refresh rate and use of third-party materials.

3D Printer Specifications:

- 230 x 230 x 230 mm (9.1 x 9.1 x 9.1 inches) build volume

- 1,480 x 850 x 2,040mm (58.3 x 33.5 x 80.3in) printer dimension

- Build speed of up to 20 mm/hour

- 24 hour cycle time

- 0.08 / 0.1 / 0.15 / 0.2mm layer thickness with 0.2mm accuracy

- 1 x 30W CO2 laser

- Powered by two advanced software suites, Buildware and SLSware

- Inert gas control system

- Compatible with nature PA / black PA / white PA / composite PA / flexible PA / high temperature PA / TPU

Pros:

- Wide material compatibility, including recycled powders

- Affordable system for cost-effective printing

Cons:

- Only suitable for industrial use and not for beginners

Best for:

Designers, manufacturers, or 3D printing services looking for an affordable advanced printer to create parts efficiently across various industries.

6. Nexa3D HSE™ 180 Series: Fastest filament 3D printer

The HSE 180 series operate at a remarkable five to 15 times the speed of its competitors, ensuring the ability to unlock swift manufacturing of prototype or end-use products.

The HSE 180 printers, comprising the HSE 180LT, HSE 180ST, and HE 180HT, feature an X-Y stage equipped with linear servo motors to address longstanding challenges in additive manufacturing, specifically those related to strength, speed, and scalability that have traditionally constrained the industry. These printers easily achieve printing speeds of up to 500 mm/s with a swift 1 m/s travel speed.

With large build volumes and build plates that accommodate 85% of the world’s jigs and fixtures, the HSE 180 series printer can efficiently produce substantial components. Its open ecosystem makes it ideal for exploring any material, including industrial-grade high-temperature materials.

Nexa3D’s HSE 180 Series of 3D printers are employed across various industries, including aerospace, the medical field, oil and gas, and even automotive for 3D printing car parts.

3D Printer Specifications:

- 690 x 500 x 600 mm build volume

- Hozzle™ heated nozzle with nozzle diameters 0.4, 0.8 mm

- 0.081 mm XY and 0.005 mm Z motion system accuracy

- One print head

- 1.75mm filament diameter

- 4 KVA, 220/240V 20A for LT machine and 40A for ST and HT machines, Single Phase 50/60 Hz electrical requirements

- 850kg net weight

- 1590 x 1350 x 2490 mm printer dimension

Pros:

- Suitable for large volume production

- Can print a wide array of 3D printing materials, including Essentium Materials

- Suitable for use across various industries

Cons:

- Not suitable for use by hobbyists

Best for: High volume production of various structures from different quality materials across various industries.

Explore all HSE 180 models in the series.

7. Nexa3D HSE™ 280i: Best dual extrusion filament 3D printer

The HSE 280i is designed to overhaul factory floor operations, outpacing the competition at speeds up to five to fifteen times faster.

Using an X-Y stage equipped with linear servo motors, the cutting-edge HSE 280i is designed to address longstanding challenges in strength, speed, and scalability, breaking new ground in additive manufacturing.

The Nexa3D HSE 280i isn’t just another printer—it boasts true independent dual extruders (IDEX), signifying complete autonomy of each print head along the X and Y axes. Additionally, it harnesses a non-slip, high-torque extrusion system to deliver both speed and reliability. With an open ecosystem that supports limitless material options and five distinct print modes for a versatile printing experience, the Nexa3D HSE 280i offers the efficiency and flexibility to bring all 3D-printed innovations to life.

3D Printer Specifications:

- Five print modes: single head mode, copy mode, multi-process mode, support mode, and a planned future mode card Independent mode

- Build volume: 695 x 500 x 600 mm (Single head mode), 595 x 500 x 600 mm (Support mode), 595 x 500 x 600 mm (Multi-process mode

Two print heads - Gen 5 Hozzle™ Heated Nozzle

- Print speed of 500 mm/s

- Filament diameter of 1.75 mm

- 0.4, 0.8 mm Nozzle diameters

- Nozzle temperature up to 550ºC

- 200–240 VAC, 40A, single/dual phase electrical requirements

- 1590 x 1350 x 2490 mm printer dimensions

- 850kg printer weight

Pros:

- First-ever industrial 3D printer to offer true independent dual extruders for complete printing autonomy

- Generous build volume allows for printing large parts or multiple small parts

- Offers printing speeds up to 15 times faster than conventional filament 3D printers.

Cons:

- Suitable for industrial use but not for beginners or hobbyists

Best for: Use in manufacturing scenarios where swift printing, scalability, versatility, strength, and flexible 3D printing are priorities during production.

8. Nexa3D QLS820: Best SLS 3D Printer for High-Throughput Manufacturing

The Nexa3D QLS 820 is another advanced 3D printer from Nexa3D. With the highest throughput in its class, this thermoplastic 3D printer is a quad laser system with unprecedented production capabilities designed with automation and scalability. It’s about 60% faster than the existing industry standard – with double the average packing density.

The QLS 820 takes 3D printing to a new level, producing up to four times the throughput of traditional laser sintering 3D printers and other polymer powder bed technologies. QLS 820’s smart automation removes pain points in capacity utilization and downstream labor intensity and can print about 8 liters per hour at a 20% job density rate.

Its wide-use temperature range, open-source platform, and inert processing atmosphere allow for printing various materials, including PA11, PA12, and polypropylene, as well as PA12 composite materials with glass, aluminum, and carbon fiber billed options. glass, aluminum, and fiber-filled options.

3D Printer Specifications:

- 350 x 350 x 400 build volume

- Prints up to an impressive 8 liters/hour

- Removable automated build unit and modular material processing station

- Web dashboard interface

- Power handling and refreshing station

- 4x 100W CO2 laser type

- Automation-ready architecture featuring Siemens PLC factory automation controls

- Open Platform with inert, high-temperature capabilities

Pros:

- Powered by quantum laser sintering which delivers high-throughput, premium production capabilities at 8L per hour at 20% packing density.

- Incredible speed, end-to-end traceability, centralized printer management, and real-time data monitoring.

- Modular Material Processing Station (MMPS) enables safe, powderless, and efficient handling of materials.

- Nexa3D QLS 820 software offers fleet management, print preparation, and real-time printer performance.

Cons:

- Best for very large print volumes, so it may not be a great fit for smaller budgets.

Best for: High-volume production manufacturing in a variety of materials. Injection mold tolerances for full production capabilities, including high-temperature thermoplastics like PBT and PA6 materials.

Learn about the QLS 820 3D printer.

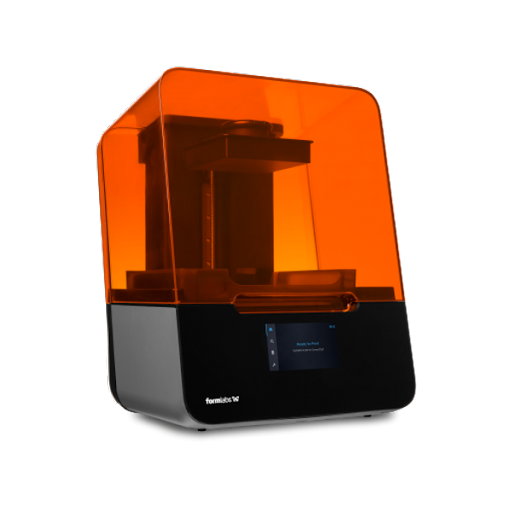

9. Formlabs Form 4: Best Budget Desktop 3D Printers for Prototyping Beginners

Formlabs Form 4 builds on its predecessor’s features, the Formlabs Form 3+. Unlike the Formlabs Form 3+, the Formlabs Form 4 uses masked stereolithography to improve its speed and accuracy. The Form 4 is driven by Formlabs’ new Low Force DisplayTM print engine, some ultra-high power LEDs, optical filters, and a liquid crystal display.

3D Printer Specifications:

- Stereolithography 3D printing technology

- Build volume of 7.9 × 4.9 × 8.3 inches

- LCD screen interface

- 100 mm/hour

- Wi-Fi compatibility

Pros:

- Offers good print quality and an optimized workflow.

- Relatively affordable.

Cons:

- It may take some time to understand its software.

- Closed material platform so you must use Formlabs branded resins.

Best for: IUsers that require speed for industrial production.

10. Creality Ender 3 V2 Neo: Best FDM Desktop 3D Printer

The Creality Ender 3 V2 Neo is a desktop 3D printer with reliable results and quality. The device has several features that make it accessible for new users, including its CR touch auto-leveling and quiet print technology.

However, it uses FDM technology, which can be less accurate than other technologies like Masked stereolithography (mSLA) and its subcategory lubricant sublayer photocuring (LSPc).

3D Printer Specifications:

- 220 x 220 x 250 mm build volume

- Maximum printing speed of 120mm/S

- 1 nozzle with diameter of 0.4mm

- Full-metal Bowden extruder

- CR touch auto leveling

Pros:

- A budget-friendly option for beginners.

- Auto-leveling and quiet print technology.

- Lightweight and easy to use.

Cons:

- FDM technology isn’t always as accurate as other 3D printing technologies.

- It lacks an inbuilt patented 3D printing software.

Best for: The Ender 3 V2 Neo is best for new users that want to use FDM technology.

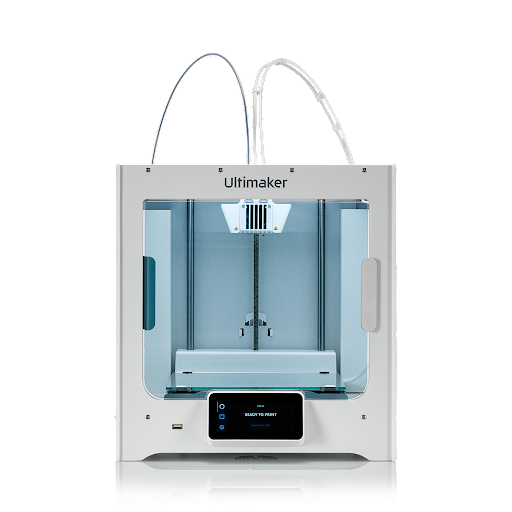

11. Ultimaker S3: Best Desktop Metal 3D Printer

Ultimaker S3 is a desktop 3D printer for professionals offering precision and fast printing speeds. The S3 has an open material platform that enables users to work with various materials and sizes, including nylon, polycarbonate, TPU, and PETG.

It’s equipped with swappable 0.4-to-0.8mm nozzles that allow users to get the necessary resolution for their parts.

3D Printer Specifications:

- 230 x 190 x 200 mm (9 x 7.4 x 7.9 inches) building volume

- Fused deposition modeling (FDM) technology compatible with 2.85 mm filament

- Build speed of less than 24 mm³/s

- Dual-geared feeder reinforced for composite materials

- Nozzle temperature between 180-280°C and 20 – 140 °C heated glass build plate

- Operating sound of less than 50 decibels

- 6.9, 6.9, 2.5 micron XYZ resolution

- 4.7-inch (11.9 cm) color touchscreen display

- Supported on MacOS, Windows, and Linux

Pros:

- Swappable nozzles offer flexibility in terms of resolution.

- Its open material platform allows for a broad range of materials and sizes.

- The semi-enclosed design ensures consistent temperature during the printing process.

- It prints metal parts.

Cons:

- It is relatively expensive compared to other desktop 3D printers on the market.

- It has limited connectivity options for other devices and networks.

Best for: Best for professionals who require metal printing.

12. 3D Systems ProX SLS 6100: Best 3D Printer for Large Projects

The ProX SLS 6100 is an industrial 3D printer from 3D Systems designed for large-scale, production-level 3D printing. The ProX SLS 6100 is powered by selective laser sintering technology and has a powder bed with a build envelope capacity of 381 x 330 x 460 mm, making it best for large parts and small series productions.

3D Printer Specifications:

- 381 x 330 x 360 mm (15 x 13 x 18 inches) build volume

- Closed material system that prints only DuraForm materials

- 100 W / CO2 laser with a build rate of 2.7l/h

- Power requirements of 208 VAC/10 kVA, 50/60 Hz, 3 PH

Pros:

- Produced by one of the oldest 3D printing companies in the world.

- Large build volume.

Cons:

- Relatively expensive compared to other 3D printing technology

- Expensive first-time investment

Best for: Printing durable parts in industries such as aerospace, automotive, medical, and consumer products.

13. Stratasys F370: Best Industrial FDM 3D Printer

The Stratasys F370 is an industrial-grade 3D printer designed for professional use. While it’s good for printing complex parts, the F370 3D printer has a smaller build volume than other top industrial 3D printers. It also uses Fused Deposition Modeling, which can be slower than other additive manufacturing technologies.

Source

3D Printer Specifications:

- 355 x 254 x 355 mm build volume

- Printing platform that supports 8 materials

- Cartridge capacity of 4 (2 models, 2 supports

- Automatic material changeover

- Maximum noise level of 46 dB during build, 35 dB when idle

- Compatible with GrabCAD Print & Insight and GrabCAD Print Pro

- Wireless-ready network compatibility

Pros:

- Quiet 3D printing process.

- Open material platform.

Cons:

- Smaller build volume.

- Limited FDM 3D printing technology.

Best for: Users looking for an industrial FDM printer

14. Markforged X7: Best carbon fiber 3D printer

Markforged X7 is a carbon fiber 3D printer designed for industrial-scale, production-level 3D printing. Its build volume is 330x270x200mm and is powered by FDM technology, which enables it to print parts with high strength and stiffness.

The X7 also comes with onboard Eiger software that allows users to tweak settings like temperature, speed, and layer height.

3D Printer Specifications:

- 330 x 370 x 200 mm ;13.0 x 10.6 x 7.9 inches) build volume

- Fused filament fabrication (FFF) and Continuous fiber reinforcement (CFR) printing technology

- Kinematic coupling print bed

- Second-generation extruder, out-of-plastic and out-of-fiber detection extrusion system

Pros:

- Large build volume.

- An inbuilt 3D printing software with various adjustability options.

Cons:

- High price point.

- FDM technology can have intrinsic limitations.

- Locked print settings exclusively for Markforged filaments.

Best for: Ideal for parts with high strength and stiffness, such as tooling, fixtures, and jigs.

15. PRUSA Mini+: Best budget 3D printer with color

PRUSA Mini+ is a desktop 3D printer that uses FDM technology and comes with an integrated automatic calibration system that helps to ensure good prints. The Mini+ also uses an open filament system, making it easy to use various materials like ABS and PLA.

3D Printer Specifications:

- 7″×7″×7″ (18×18×18 cm) build volume

- Sensorless homing and mesh bed calibration

- Magnetic heat bed with removable spring steel sheets

- Max nozzle temperature of 270°C and max heat bed temperature of 100°C

- 2.8’’ graphic 65k color screen with G-Code preview

- USB port, RJ-45, and Wi-Fi module connectivity

- Compatible with remote print management system via Prusa Connect

- Open source system

Pros:

- Fully enclosed frame to protect prints from drafts and dust.

- Lightweight and easy to set up.

Cons:

- Unable to achieve high-quality surface finish since it’s a filament-based printer.

- Limited customization options for parts.

16. Bambu Lab A1 Mini: Best 3D printer for beginners

Bambu Lab A1 Mini is a filament 3D printer with a steel frame structure and a 180 x 180 x 180 mm build volume. It features an all-metal hot end, stainless steel nozzles with a diameter of 0.4mm, and a PEI build plate that reaches a maximum temperature of 80°C. The Bambu Lab A1 comes with a touch-screen display, Wi-Fi connectivity features, a camera, power-loss recovery, and a platform that supports a range of materials, including PLA, PETG, TPU, and PVA.

3D Printer Specifications:

- 180 x 180 x 180 mm build volume

- Maximum printing speed of 500 mm/s and max acceleration of 10000 mm/s²

- 2.4 inches 320*240 IPS Touch Screen

- Touch Screen, APP, PC Application control interface

- Low rate camera of up to 1080p

- Filament runout sensor and filament tangle sensor

- Power loss recovery

- Supports third-party slivers

Pros:

- Supports multi-color printing

- Intuitive interface for beginners

Cons:

Not ideal for printing larger items

Not suitable for beginners and only suitable for professionals

Best for: Beginners looking for a plug-and-play 3D printer with high-speed precision.

17. Creality Ender 3 V3 KE: Fastest budget 3D printer

The Ender 3 V3 KE is a high-speed filament 3D printer with a build volume of 220 x 220 x 240mm and a printing speed of 300mm/s. It uses a hotend with a 60W ceramic heater to manipulate a range of filaments such as ABS, PETG, Hyper PLA, TPU (95A), and ASA filaments into durable parts.

The Creality Ender 3 V3 KE offers auto calibration, an intuitive user interface, and cloud printing to control the printer from anywhere.

3D Printer Specifications:

- 220 x 220 x 240 mm build volume

- Average printing speed of 300mm/s and maximum printing speed of 500mm/s

- Max acceleration of 8000 mm/s2

- PEI flexible build plate

- 4.3-inch color touchscreen display

- 32-but silent motorboard

- Power loss recovery and filament runout sensor

- Klipper firmware

- Supports Creality Print, Cura, and Simplify3D slicing software

Pros:

- Affordable open source platform

- User-friendly wireless control

Cons:

- Klipper interface is limited

- No enclosed system

Best for: Beginners and enthusiasts for a high speed printer with user-friendly features.

Differentiating between the best 3D Printers

Before investing in a 3D printer, it is important to understand and differentiate between the different types available. Below are some comparisons between the different 3D printers available today.

Resin vs Filament 3D Printers

One of the primary distinctions in 3D printing is the type of technology used. While various types of 3D printing technologies are available, two main categories that stand out are resin-based and filament-based printers.

Resin 3D printers, such as the Nexa3D XiP Pro, use a liquid photopolymer resin that is cured layer by layer using UV light. These printers are known for producing highly detailed parts with smooth surfaces, making them ideal for applications like jewelry, miniatures, and dental models. However, printers for 3D printing with polymers typically have smaller build volumes and require more post-processing steps than filament printers.

Filament 3D printers use solid thermoplastic filaments that are melted and extruded through a nozzle to build up the desired object. These printers, which include models like the Nexa3D HSE 180 printers, are generally more affordable and have larger build volumes. They are well-suited for creating functional prototypes, end-use parts, and larger objects. Filament printers are also easier to use and maintain compared to resin 3D printers.

Budget vs Professional 3D Printers

Another key consideration is whether you need a budget-friendly desktop printer or a more advanced, professional-grade, and more expensive machine.

Budget 3D printers, like the Creality Ender 3 V2 Neo, are designed for hobbyists and small businesses. These printers offer good value for money, with features such as auto-leveling, heated build plates, and Wi-Fi connectivity. While they may not match the performance of professional printers, budget models can still produce high-quality prints and are a great entry point into the world of 3D printing.

Professional 3D printers, on the other hand, are built for industrial applications and demanding uses. These printers, such as the HSE 280i, offer faster printing speeds, larger build volumes, and more advanced features. They are designed for high-volume production, rapid prototyping, and creating end-use parts. Professional printers often come with a higher price tag but deliver unparalleled performance and reliability.

When choosing between budget and professional 3D printers, consider factors such as your budget, the size and complexity of the parts you need to print, and the required print quality and speed. If you have a limited budget or are just starting out, a desktop printer may be the best choice. If you have demanding production needs or require industrial-grade performance, investing in a professional 3D printer may be worth the higher cost.

Desktop vs Industrial 3D Printers

Before choosing the best 3D printer for your products, it’s important to understand the key differences between desktop and industrial models.

Desktop 3D printers are no longer just for hobbyists and beginners. Professional desktop 3D printers offer convenience, accessibility, and a workforce unhampered by hardware limitations.

Desktop 3D printers are best for the rapid prototyping of small products to optimize workflows right in your office. They’re either fused deposition modeling (FDM) 3D printers or those that use resin-based vat polymerization. The latter include stereolithography (SLA), direct light processing (DLP), masked stereolithography (mSLA), and its subcategory lubricant sublayer photocuring (LSPc). These use a programmable light source to selectively cure part layers in a vat of photoreactive resin.

However, not all FDM or vat polymerization printers are desktop printers; they offer industrial-grade technologies as well. When most people think of industrial 3D printing, they think of powder-bed fusion and metal 3D printing technologies, but this is not always the case. In addition to the advanced technologies, industrial 3D printers also include Fused Deposition Modeling (FDM) and Vat Photopolymerization or resin 3D printing.

Today’s industrial 3D printing is highly reliable and consistent, has a high resolution, can print with engineering-grade materials, offer high-speed printing, have an ecosystem of materials and software supporting the 3D printer, have a large build volume, require little maintenance, and have foolproof safety features.

Industrial 3D printers are designed for large-scale production and are mainly used in manufacturing operations. The printer’s ability to create complex items from various materials using multiple techniques is a major plus for industrial setups. The cost of these printers can be quite expensive, but the results they offer often justify the investment.

Download the Guide

Technical Review of LSPc®

Unleash your manufacturing potential with this guide, which explores the limitations of traditional SLA, offers a technical overview of Lubricant Sublayer Photo-curing (LSPc), and shows you how to achieve up to 20x productivity gains.

More 3D Printer Picks

For more ideas on the best 3D printers, the following 3D printers have caught our attention.

Fastest 3D Printer

When it comes to speed, the 3D printer market has a wide array of printers with varying speed levels to offer. However, it is important to choose printers that not only offer swift printing speeds that can increase daily throughout but also those who do so with compromising print quality.

Some of the fastest 3D printers in the market include:

- Nexa3D XiP Pro

- Nexa3D NXE 400Pro

- Nexa3D QLS260

- Nexa3D HSE™ 180 Series

Best 3D Printers for Beginners

Hobbyists and new professional users often look for affordable and easy-to-use 3D printers that offer great value for their cost. Beginner 3D printers must offer high-quality prints with minimal setup time, hassle, and speed.

Therefore, the best 3D printer for beginners is the Nexa3D XiP which combines a compact footprint and a large build volume to offer a good balance of speed and quality.

Other reputable beginner 3D printers are:

- XYZPrinting da Vinci Mini

- Ender 3 Pro

- Creality CR6-SE

- Formlabs Form 3L

- Original Prusa i3 MK3S+

- Anycubic Kobra

Best 3D Printer for Small Businesses

Small businesses looking to scale need improved productivity and throughput at an affordable rate. The ideal 3D printers for small businesses should have quick print times and high accuracy so businesses can quickly produce prototypes for analysis or end-use parts for commercial production.

Nexa3D’s XiP is another winner here. The XiP is capable of full build volume print jobs that last as little as one hour for production applications. You can use 3rd-party materials and have a controlled experience–all for an incredibly affordable price.

How to Choose the Best 3D Printer

Choosing the right 3D printer for your printing needs is ideal for the success of any small or large-scale manufacturing process. Whether you are looking for an affordable desktop printer or a more industrial-grade powerhouse, it is important to consider certain important features in order to make the best choice.

Some of the factors to consider include:

Product Requirements

The most important factor to consider when choosing a 3D printer is your printing needs. Factors such as the expected print size, resolution, and detail accuracy are key determinants of the type of 3D printer to invest in.

Your Work Space

The size of your work space is another important factor to consider. Industrial 3D printers often require dedicated spaces due to their size and power requirements, while desktop printers are designed to fit comfortably in home or office environments.

Measure your available space and ensure the printer you choose will fit without compromising your workflow.

3D Printing Speed

The projected timeline for your project is also an important factor to consider. If time-to-market is a priority, consider investing in printers that can deliver high-quality parts quickly, such as Nexa3D HSE printers.

3D Printing Material

Different printing technologies, such as FDM, SLA, and SLS, are compatible with various 3D printing materials, each offering unique properties and applications. Determine the materials you’ll need for your projects and ensure the printer you choose can handle them effectively.

Want to learn more about the different 3D printing materials for your processing needs?

Explore Nexa3D’s guide to 3D printing materials.

Costs of 3D Printing

Consider the overall costs associated with 3D printing, including the initial 3D printer cost, ongoing maintenance, and material expenses. Desktop printers typically provide a more affordable entry point for hobbyists and small businesses.

Industrial 3D printers, on the other hand, may have higher upfront costs but also often offer better long-term value due to their efficiency, reliability, and ability to handle large-scale production. However, certain printers like the Nexa3D XiP offer the best of both worlds by combining affordability with professional capabilities.

Choose the Best 3D Printer for Your Additive Manufacturing Projects

Choosing the best 3D printer–whether desktop or industrial–can and should take some time. The right 3D printer allows you to move from days or even weeks of prototyping and development time to hours or minutes. This means you can enjoy faster design cycles, a quicker time to market, and, in some cases, eliminate reliance on traditional manufacturing technologies.

Though there is an array of 3D printers to choose from, we’re confident that ultrafast 3D printing from the Nexa3D XiP and NXE series can change the future of your products and business.

These 3D printers run on the most powerful 3D printing technology, Lubricant Sublayer Photo-curing (LSPc), and offer advanced features that make 3D printing highly accurate at incredible speeds without compromising accuracy.

Ready to see it in action?

Request a free sample part to experience the capabilities of ultrafast 3D printing.